Full-automatic omni-directional unmanned forklift

An unmanned forklift, fully automatic technology, applied in the direction of the lifting device, etc., can solve the problems of excessive turning radius, reduced space utilization rate, high accident rate, etc., and achieve the effect of zero turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

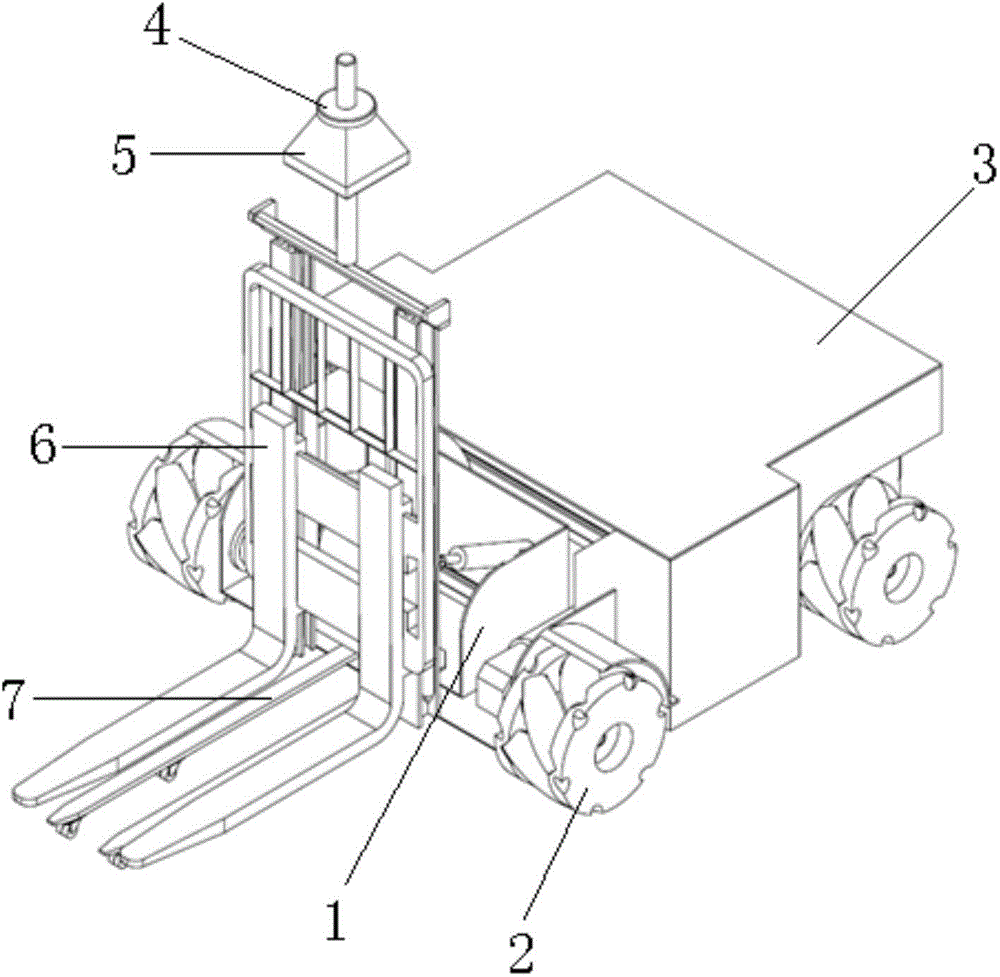

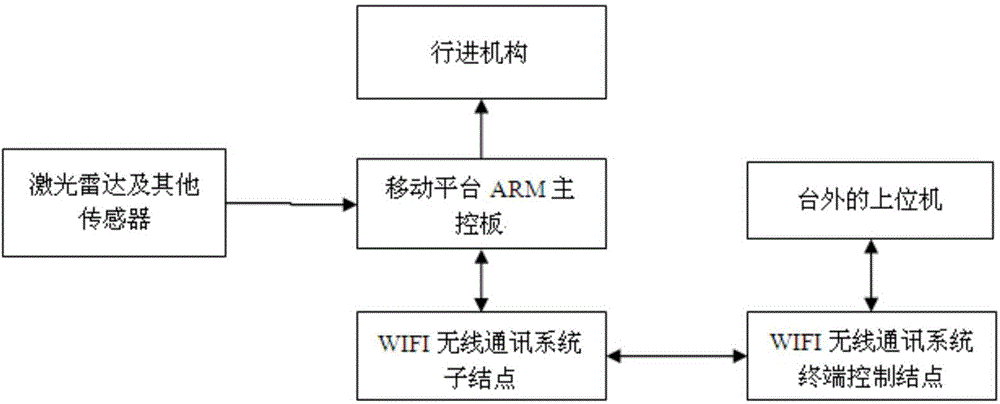

[0017] like figure 1 As shown, a fully automatic omnidirectional unmanned forklift described in the embodiment of the present invention includes: a forklift chassis 1, two groups of mecanum wheels 2 are installed on the bottom of it; a battery compartment 3, which is installed on the forklift chassis 1 Upper part; bracket, which is installed on the front of the forklift chassis 1; wherein the upper part of the bracket is equipped with a navigation device 5 and a 3D vision device 4, and the front of the bracket is also equipped with a door frame device 6 and a stabilizing device 7; the navigation device 5. It is used to guide the forklift to walk; the 3D vision device 4 is used for positioning when viewing the fork and picking up the goods; the stabilizing device 7 is located in the middle of the door frame device 6 and is used to control the stability of the goods, and its end is fixed on the forklift Chassis 1 interior. An ARM main control board that receives signals from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com