A kind of curing agent for solid phenolic epoxy resin powder and one-step preparation method thereof

A phenolic epoxy resin and epoxy resin technology, which is applied in the field of special additives for polymer materials, can solve the problems that affect the water resistance and corrosion resistance of the cured product, the molecular weight distribution of the product is easy to become wider, and it is not conducive to saving energy and production efficiency. and other problems, to achieve the effect of easy control of molecular weight, shortened process production steps, and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

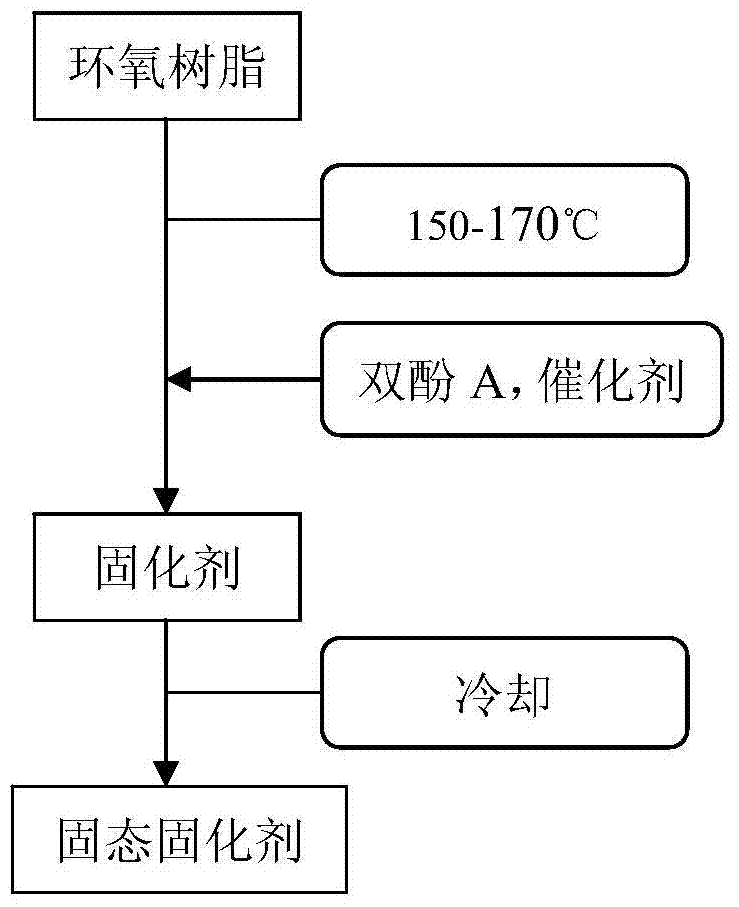

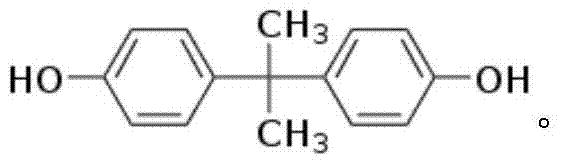

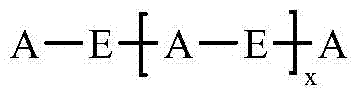

[0021] Add 100g of epoxy resin E into a 250ml three-necked flask, raise the temperature to 150°C, then add 140g of bisphenol A and 0.1g of catalyst tetrabutylammonium bromide, react for 5 hours, discharge the material, and obtain a curing agent after cooling.

[0022] The softening point of the product tested in the experiment is 94°C, the hydroxyl value is 0.5407eq / 100g, the epoxy value is 0.00017eq / 100g, and the cathodic disbonding and water resistance tests all meet the requirements.

Embodiment 2

[0024] Add 100g of epoxy resin E to a 250ml three-necked bottle, raise the temperature to 170°C, then add 125g of bisphenol A and 0.25g of catalyst benzyltriphenylphosphine chloride, react for 2.5 hours, discharge the material, and obtain a curing agent after cooling .

[0025] The softening point of the product tested in the experiment is 103°C, the hydroxyl value is 0.5011eq / 100g, the epoxy value is 0.00013eq / 100g, and the cathodic disbonding and water resistance tests all meet the requirements.

Embodiment 3

[0027] Add 100g of epoxy resin E to a 250ml three-necked bottle, raise the temperature to 150°C, then add 90g of bisphenol A and 0.15g of catalyst benzyltriethylammonium chloride, react for 3 hours, discharge the material, and obtain a curing agent after cooling .

[0028] According to the experimental test, the softening point of the product is 115°C, the hydroxyl value is 0.4721eq / 100g, the epoxy value is 0.00011eq / 100g, and the cathodic disbonding and water resistance tests all meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com