Automatic water-supplementing water seal technology of water-seal well

A technology for automatic water replenishment and water sealing wells, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of failure to prevent fire and automatic water replenishment of water sealing wells, and achieve low cost and reduce the risk of safety accidents , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

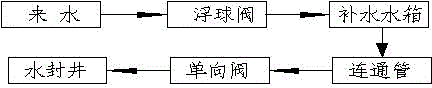

[0027] In order to overcome the problems that existing water-sealed wells cannot automatically replenish water, fail to prevent fire, and have potential safety hazards, this embodiment provides a method such as figure 1 The automatic water replenishment and water sealing process of the shown water sealing well comprises the following steps:

[0028] 1) Set up a water supply tank at a distance of 100mm to 200mm from the bottom of the water sealing well on the inner wall of the water sealing well.

[0029] 2) Lead a water supply pipeline from the water supply pipe network of the oilfield station or the high-level water tank in the station. The water supply pipeline passes through the wall of the water seal well and connects to the upper end of the water supply tank in the water seal well. Float valve, the float valve is placed in the replenishment water tank.

[0030] 3) A connecting pipe is connected to the lower end of the replenishment water tank to communicate with the wate...

Embodiment 2

[0036] This embodiment provides an automatic water replenishment and water sealing process for a water sealing well, comprising the following steps:

[0037] 1) Set up a replenishment water tank on the inner wall of the water seal well 100mm-200mm from the bottom of the water seal well. The replenishment water tank is made of stainless steel or fiberglass, and its length is 600mm-800mm, width 380mm-450mm, and height 650mm-1000mm.

[0038] 2) Lead a water supply pipeline from the water supply pipe network of the oilfield station or the high-level water tank in the station. The water supply pipeline passes through the well wall of the water seal well and connects to the upper end of the water supply tank in the water seal well. The water supply pipeline adopts de20~de63 cold and hot The water uses PP-R pipes, and the end of the water supply pipeline connected to one end of the water supply tank is connected to a float valve, and the float valve is placed in the water supply tank....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com