Skirting machine

A technology of base line and base line machine, which is applied in the direction of construction and building construction, which can solve the problems of slow working speed, flying dust, and uneven level of base line, so as to achieve high work efficiency, save physical strength, and reduce flying out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following combined with specific examples, for this invention To elaborate further:

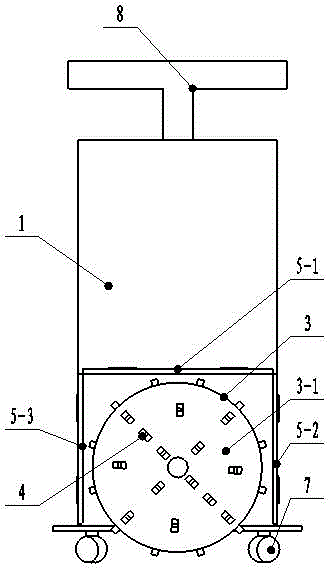

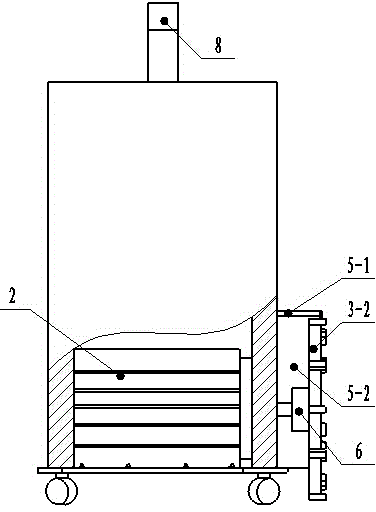

[0015] like figure 1 , figure 2 The present invention shown, it comprises walking box 1, and motor 2 is housed in the walking box 1, and the output end that motor 2 stretches out casing 1 is covered with working wheel 3, and the outer surface of working wheel 3 is working surface 3- 1. The working surface is provided with a plurality of cutting pieces 4, and the outer circumferential surface 3-2 of the working wheel is also provided with a plurality of pieces 4, and the cutting pieces 4 are evenly distributed on the outer circumferential surface 3-2, and the working wheel 3 is provided with In the protective cover, the protective cover is set on the working box 1, and the protective cover is composed of three protective plates 5-1, 5-2, 5-3, which are respectively covered on the top and both sides of the working wheel 3, and the protective plates pass through The hinge sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com