Rectangular tunnel segment steel die

A tunnel segment and steel mold technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of poor flexibility and high cost of fixed-shaped molds, and achieve the effect of good rigidity and high precision of the inner cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

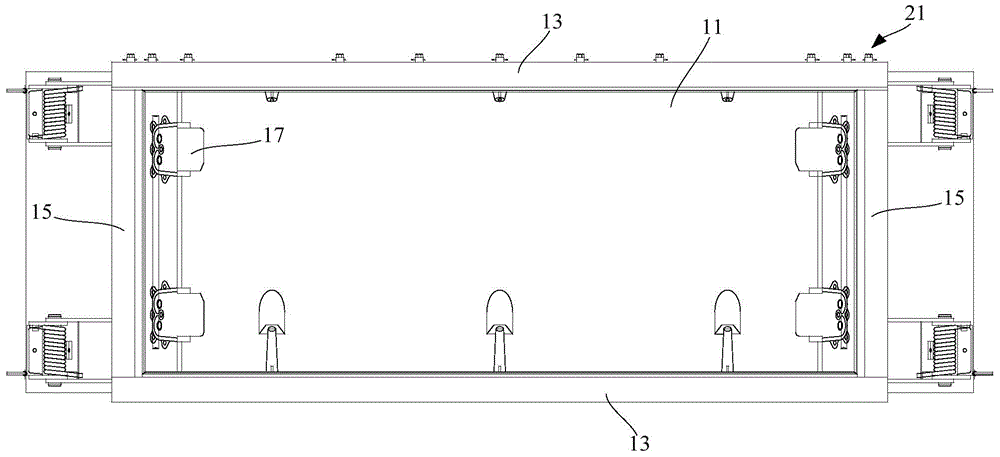

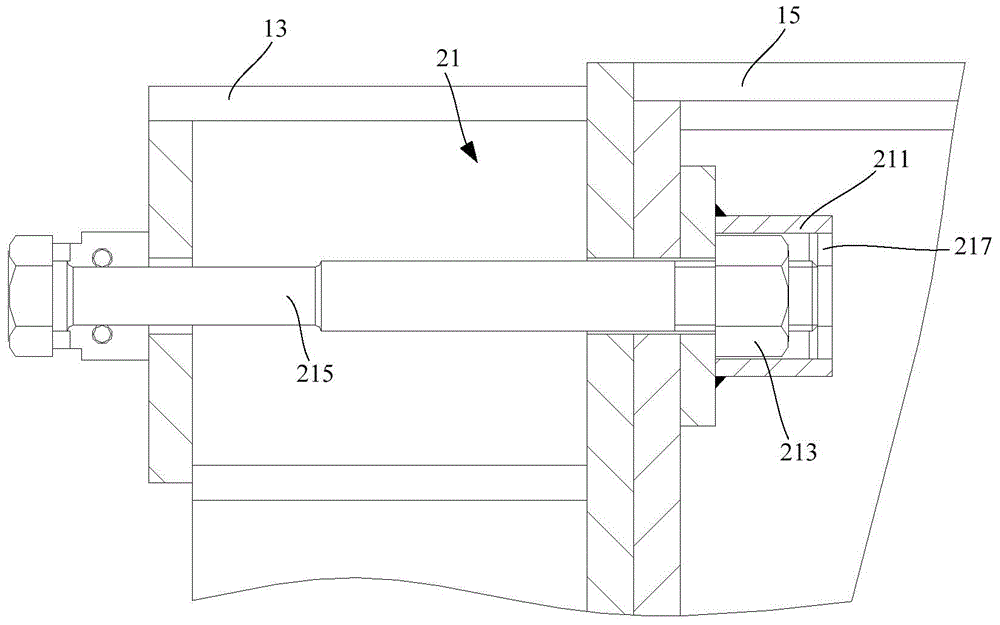

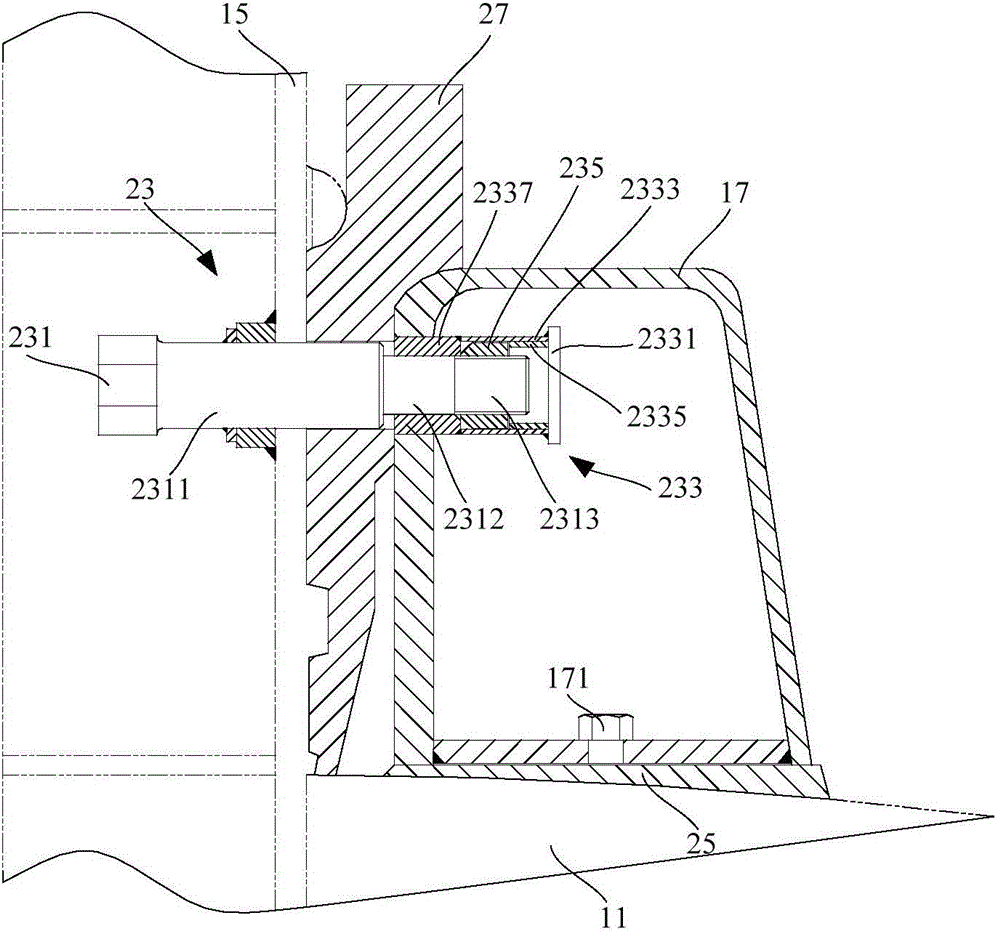

[0025] The invention provides a steel mold for rectangular tunnel segments, which is used for prefabricating segments and is suitable for rectangular shield construction. The prefabricated segments are transported to the construction site for assembly to form pipe joints in the tunnel. The tunnel segment steel mold of the present invention adopts a locking structure to connect each formwork, so that the connection operation between the formworks is convenient, the mold has good rigidity and strength, and the inner cavity has high precision. The hand hole mold core and the end mold are connected by a connection structure. The concentricity requirements of the connection hole on the end mold and the connection hole on the hand hole mold core are high, so the position of the positioning bolt is fixed. The precision requirements of the nuts of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com