Fast pipe joint insertion structure

A pipe joint and joint body technology, which is applied in mechanical equipment, couplings, etc., can solve the problems of easily affecting the sealing effect of the sealing ring, expanding the hole diameter of the sealing ring, and difficult to control the size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

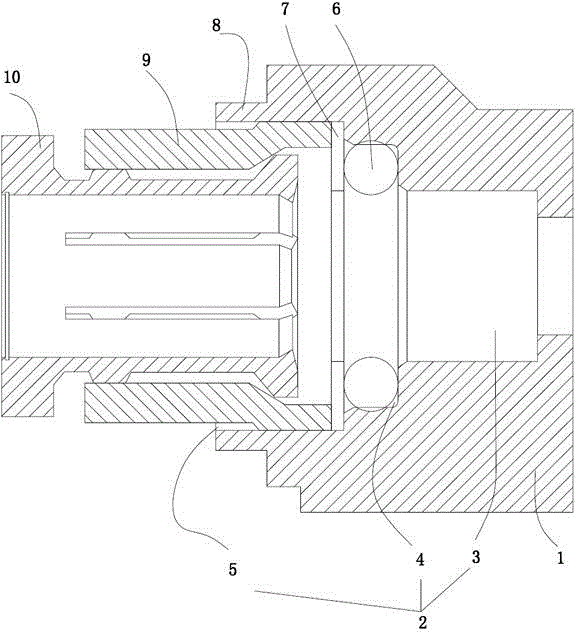

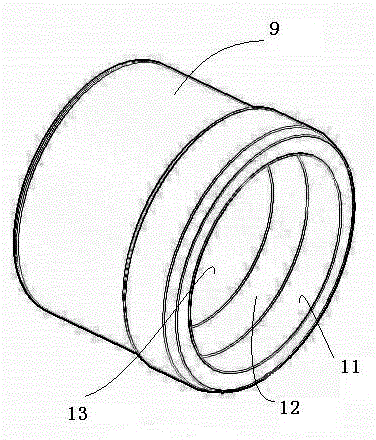

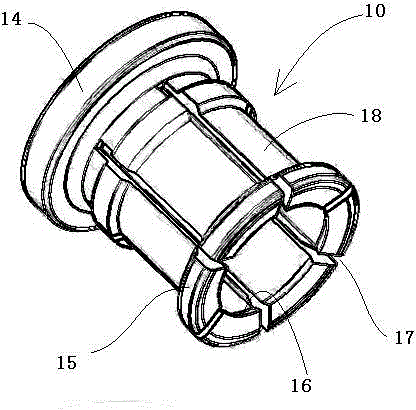

[0026] Embodiment: A kind of quick-plug structure of pipe joint (see attached figure 1 ), including a joint body 1, the joint body is provided with an inner hole 2 through which a pipe is inserted, and the inner hole is stepped. The inner hole includes a liquid hole, a channel hole 3 , an open sealing ring hole 4 and a plug hole 5 which are distributed in sequence. The diameter of the liquid hole is the smallest, followed by the diameter of the passage hole, the diameter of the open sealing ring hole is greater than the diameter of the passage hole, the diameter of the plug hole is the largest, and the diameter of the passage hole is equal to the outer diameter of the pipe. The joint body is a necking part 8 at one end of the plug hole.

[0027] A sealing ring 6 is placed in the open sealing ring hole, and the side of the open sealing ring hole facing the plug hole is an open structure, and a metal gasket 7 is placed at the inner end of the plug hole, and the metal gasket clo...

Embodiment 2

[0030] Embodiment 2: A pipe joint quick-plug structure, the inner wall of the claw of the buckle is an inclined structure, and the diameter of the inner wall at the end of the claw is smaller than the diameter of the inner wall at the root of the claw, so that the inner wall of the claw has a larger inclination Angle, when the claws buckle the outer wall of the pipe, it will not cause bite marks on the outer wall of the pipe. In order to increase the anti-off ability of the pipe, printing can be added on the inner wall of the claw to increase the friction with the outer wall of the pipe. Refer to Example 1 for all the other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com