Efficient low-heat-loss storage type gas water heater

A gas water heater, volumetric technology, applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of affecting primary air injection and unfavorable combustion, so as to reduce losses, ensure sufficient combustion, and improve combustion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

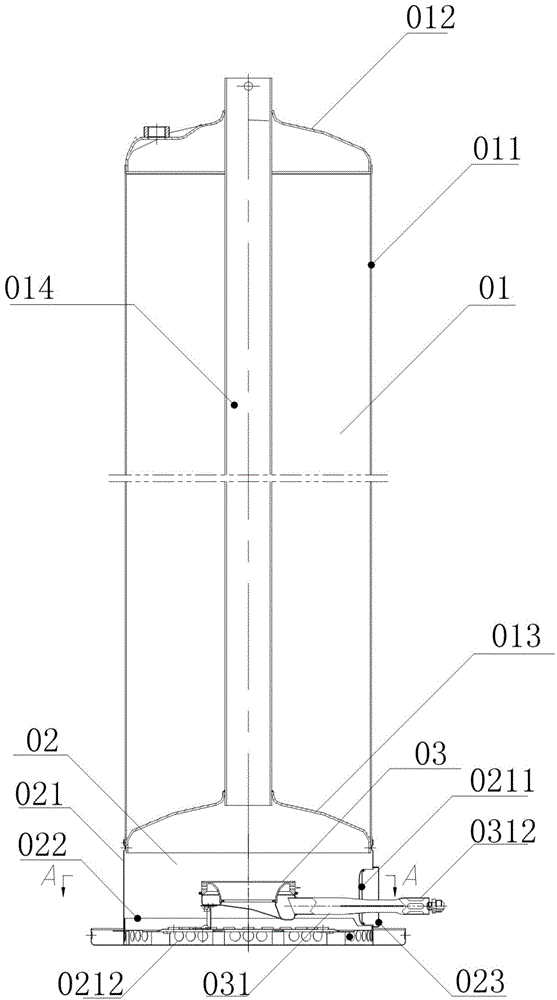

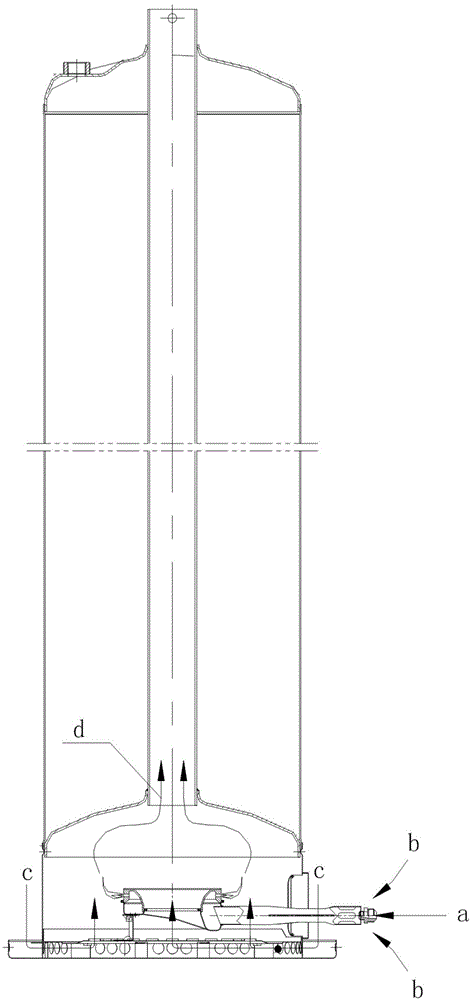

[0022] Such as figure 1 As shown, the present invention is composed of three parts: an inner tank 01, a combustion chamber 02 and a burner 03; wherein, the outer periphery of the inner tank 01 is a cylindrical body 011, and the upper and lower ends of the cylindrical body 011 are respectively equipped with convex seal heads 012 and The recessed sealing head 013 is provided with a smoke pipe 014 between the convex sealing head 012 and the concave sealing head 013. The combustion chamber 02 is placed under the recessed head 013, and the combustion chamber 02 is closed by the enclosure plate 021, the water collection tray 022, the furnace door 023 and the recessed head 013. One side of the enclosure 021 is provided with a combustion chamber opening 0211, and the furnace door 023 is mounted on the combustion chamber opening 0211.

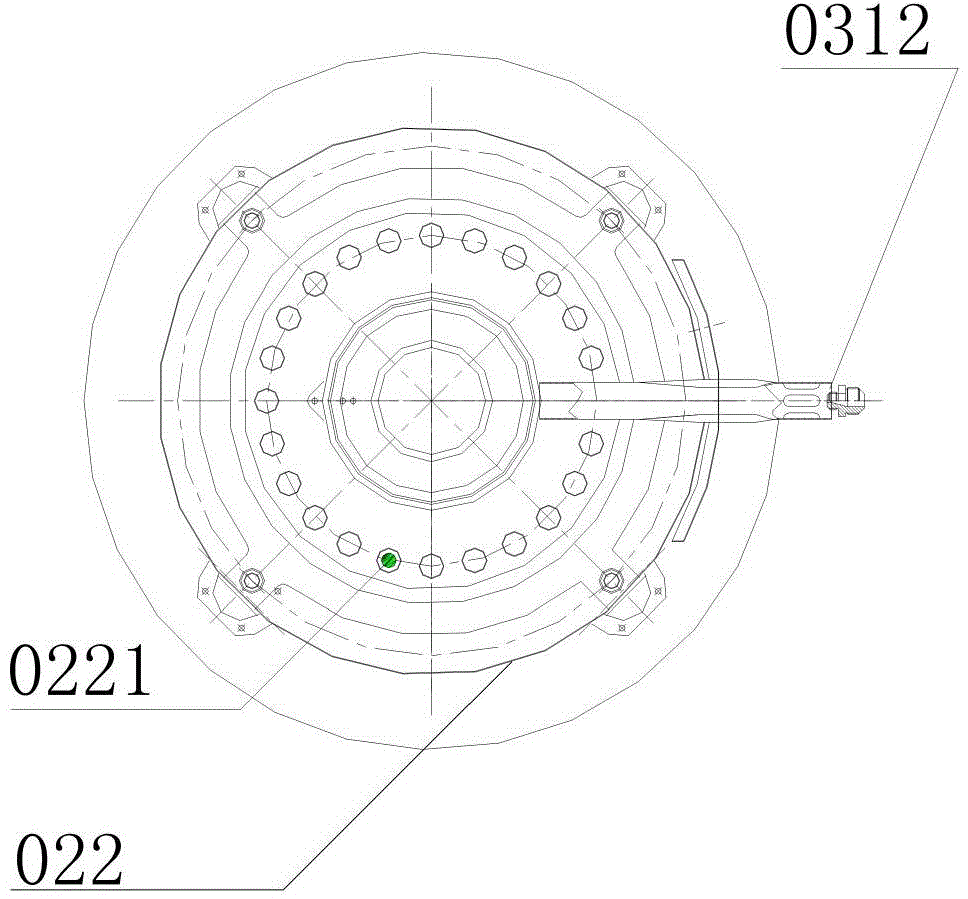

[0023] combine figure 1 and 2 It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com