Automatic load increase testing system and testing method for engine

A test system and engine technology, which is applied in the direction of engine test, machine/structural component test, measuring device, etc., can solve the problems of less test points, poor precision, low efficiency, etc., and achieve the goal of reducing running time and improving test accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

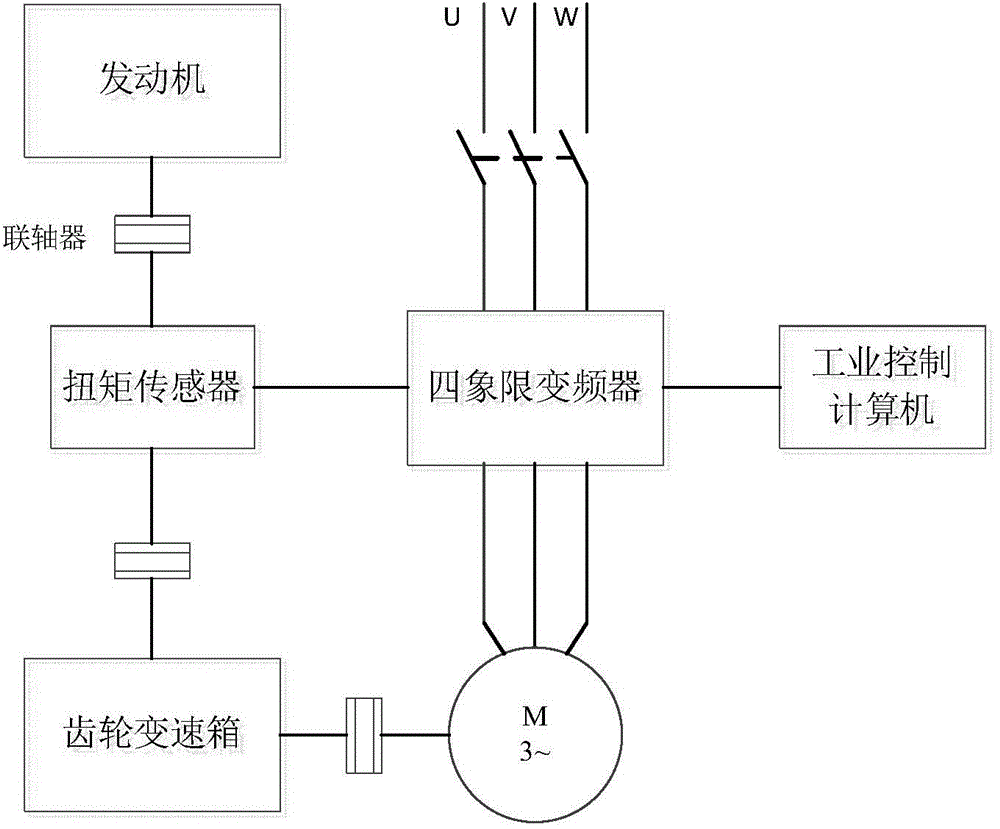

[0027] figure 1 Among them, an engine automatic load loading test system, including the engine, torque sensor, gear box, accompanying test motor, industrial control computer and four-quadrant frequency converter; the engine is connected with the torque sensor through a coupling, and the other end of the torque sensor Connected to the gear box, the gear box is connected to the test motor through the coupling, and the test motor is connected to the four-quadrant frequency converter through the cable. The torque sensor adopts the JN-338 torque sensor, and the speed and torque signals output by the torque sensor are connected to the signal acquisition module of the four-quadrant inverter through the shielded signal cable.

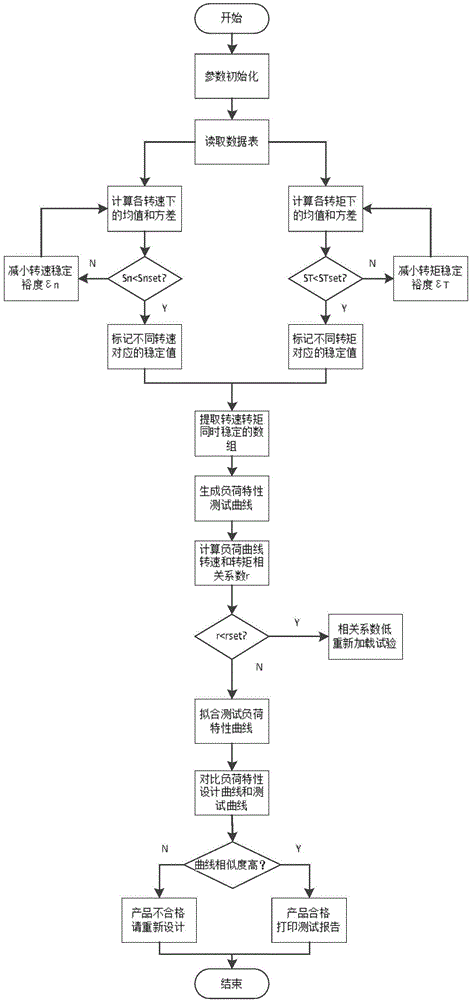

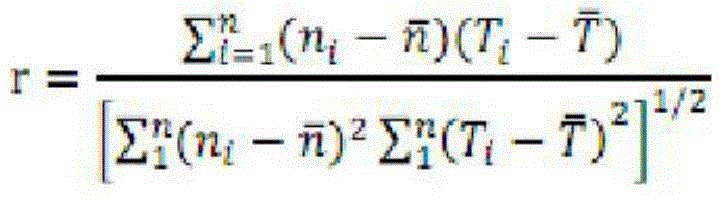

[0028] The industrial control computer uses the least square method to fit the theoretical load characteristic curve of the engine;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com