Temperature measurement and sampling device of molten steel

A sampling device, molten steel technology, applied in sampling devices, measuring devices, thermometers, etc., can solve the problems of slow sample preparation and molding, waste of smelting time, etc., and achieve the effect of simple and lightweight overall design, lightening labor intensity, and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

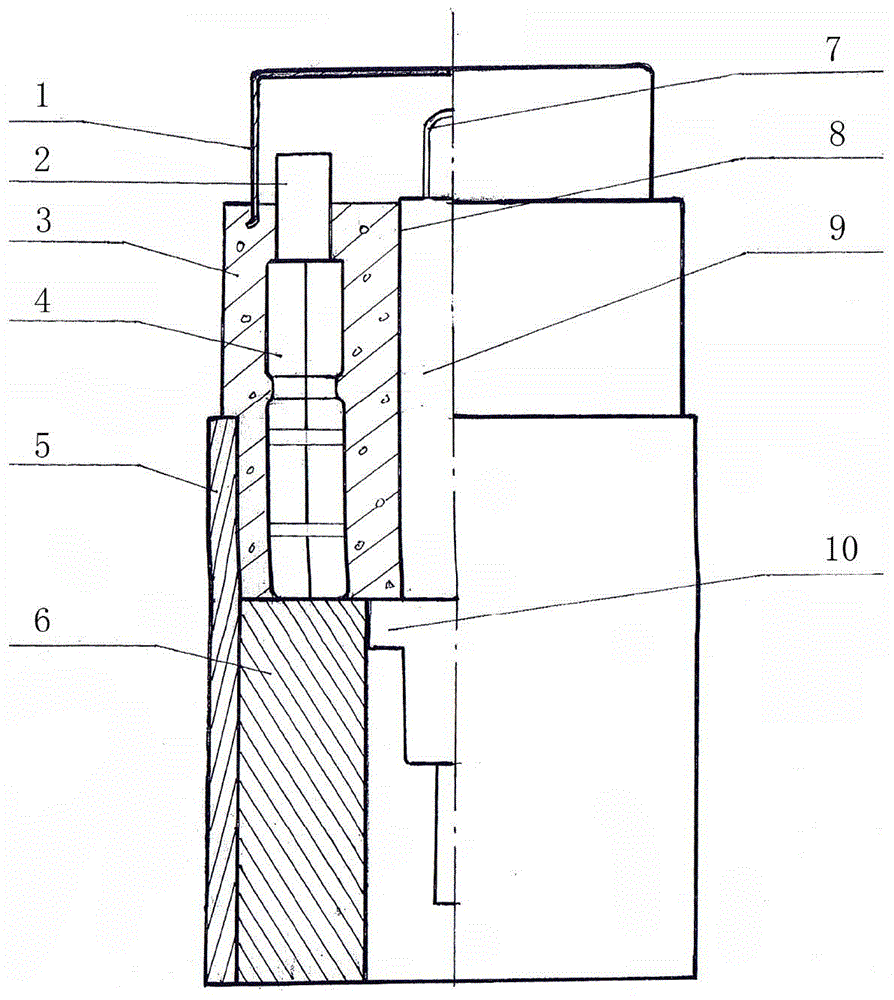

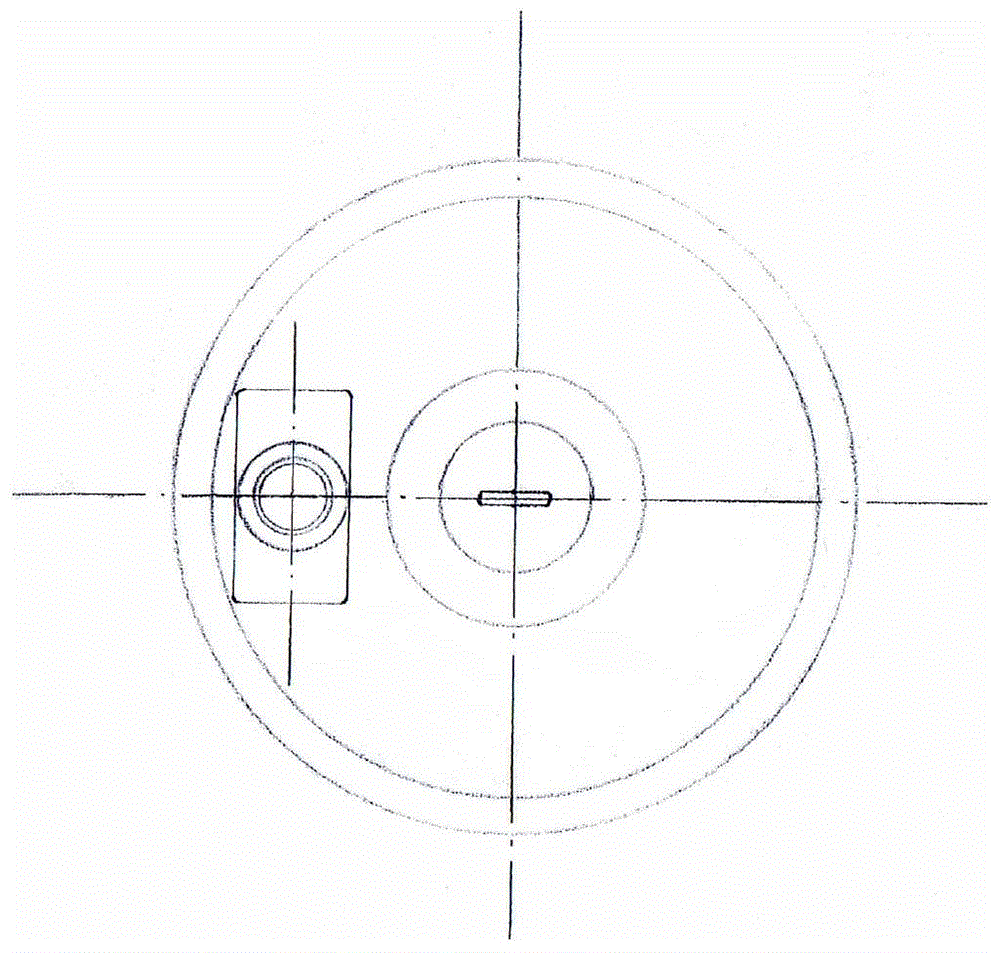

[0029] Such as figure 1 As shown, a molten steel temperature measurement and sampling device includes a sampling part, a thermocouple part, a paper sleeve part and a large iron cap 1. The sampling part includes quartz tube 2, resin coated sand 3, sampling sample box 4; the paper casing part includes paper outer sheath 5 and paper inner sheath 6; the thermocouple part includes U-shaped quartz tube 7, Thin-walled steel casing 8, thermocouple casting material 9, thermocouple mud tip 10.

[0030] The paper outer sheath 5 wraps the paper inner sheath 6, and the paper outer sheath 5 is higher than the paper inner sheath 6, and the sampling box 4 is placed on the upper plane of the paper inner sheath 6 , So that a part of it is put into the paper outer sheath 5. The upper part of the sample box 4 is fixedly connected to the quartz tube 2. The quartz tube 2 is covered with a large iron cap 1, the space formed by the bottom of the large iron cap 1, the inner side of the paper outer sheat...

Embodiment 2

[0036] A device for measuring and sampling molten steel includes a paper casing part, a sampling part, a thermocouple part and a large iron cap 1. The sampling part includes quartz tube 2, resin coated sand 3, sampling sample box 4; the paper casing part includes paper outer sheath 5 and paper inner sheath 6; the thermocouple part includes U-shaped quartz tube 7, Thin-walled steel casing 8, thermocouple casting material 9, thermocouple mud tip 10.

[0037] The paper outer jacket tube 5 covers the paper inner jacket tube 6, and the paper outer jacket tube 5 is higher than the paper inner jacket tube 6, and the sample box 4 is placed on the upper plane of the paper inner jacket tube 6 , So that a part of it is put into the paper outer sheath 5. The upper part of the sample box 4 is fixedly connected to the quartz tube 2. The quartz tube 2 is covered with a large iron cap 1, the space formed by the bottom of the large iron cap 1, the inner side of the paper outer sheath 5 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com