Creating clad materials using resistance seam welding

A clad material, resistance seam welding technology, applied in the direction of resistance welding equipment, welding/cutting medium/material, roller electrode welding, etc., can solve the problem of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

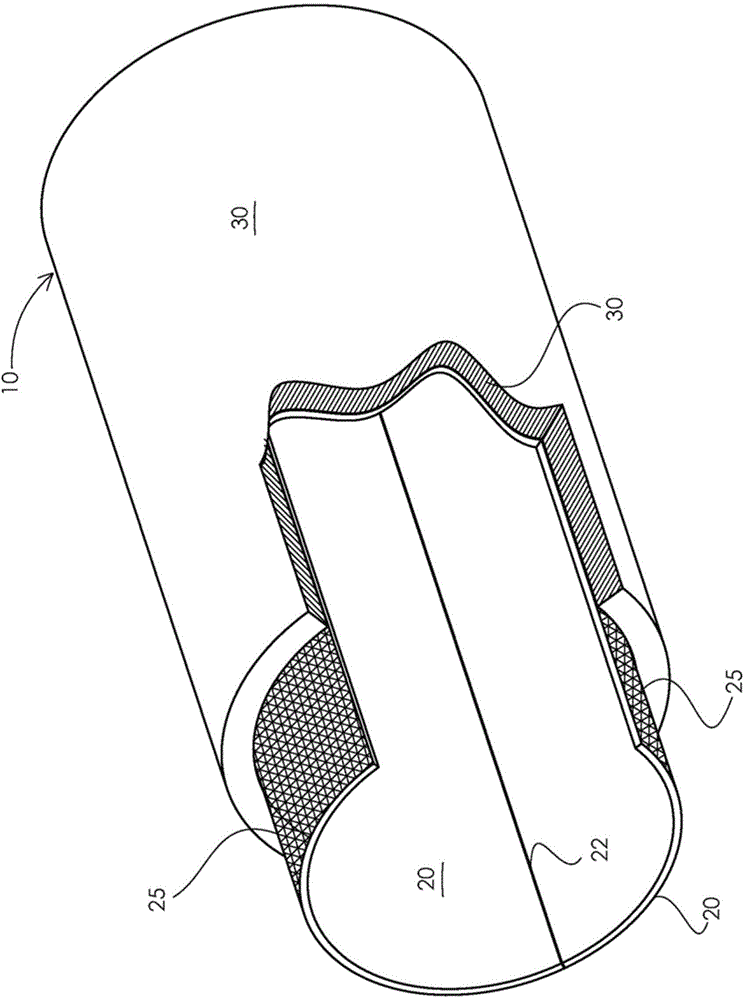

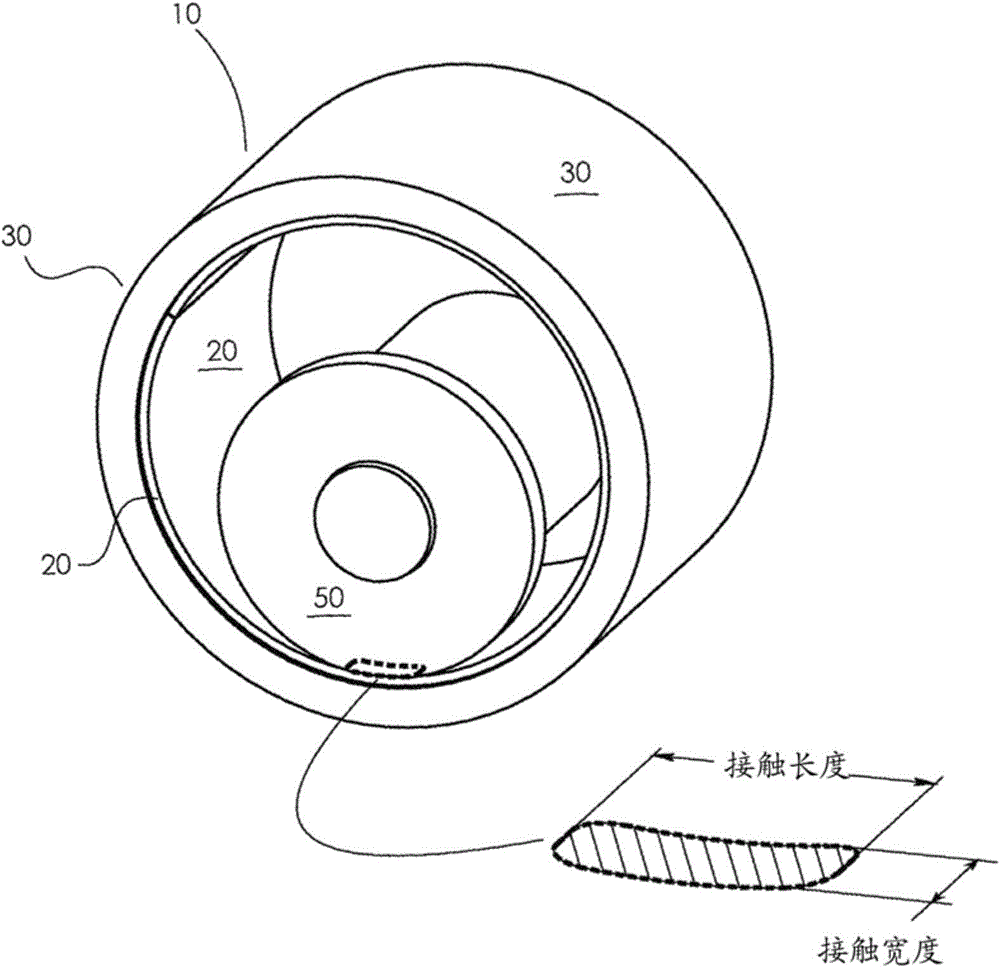

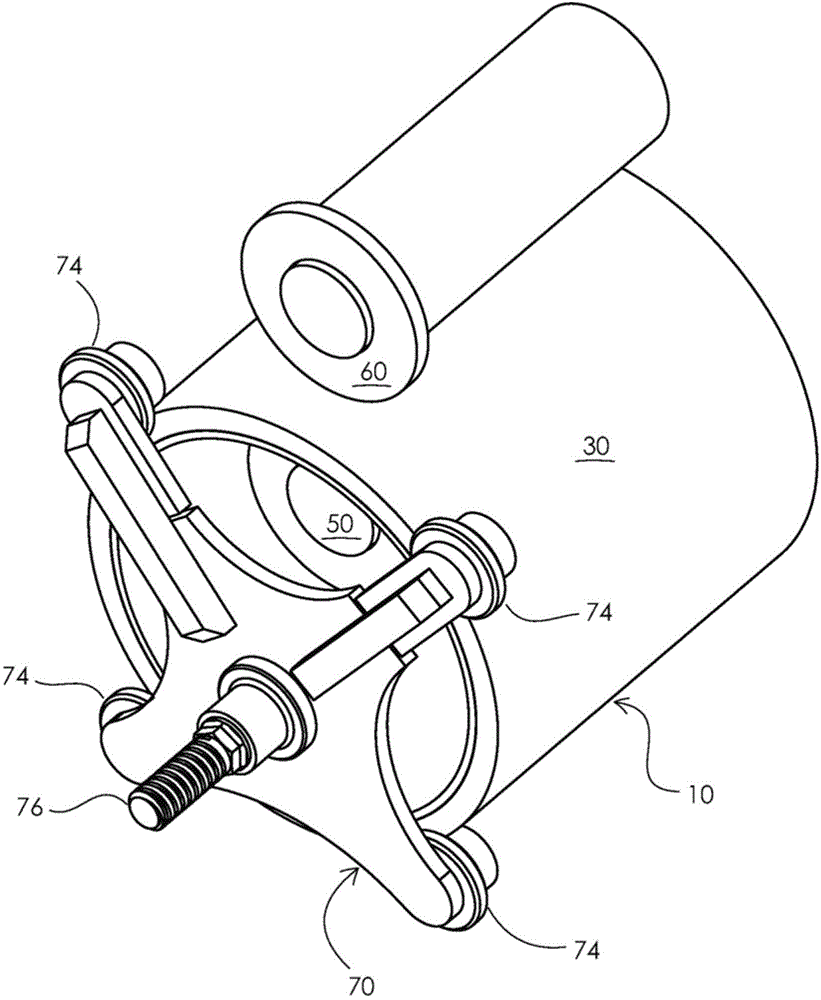

[0015] Exemplary embodiments of the present invention will now be described with reference to the accompanying drawings. Although the following detailed description contains many details for the purpose of illustration, those of ordinary skill in the art will recognize that many variations and substitutions of the following detailed description are within the scope of the invention. Accordingly, the following description of the embodiments of the invention does not lose any generality and imposes no limitations on the claimed invention.

[0016] Potential applications for the flexible wrapping system of the present invention include a range of industrial sectors including oil, automotive, power generation and consumer products. Of particular importance is the use of Corrosion Resistant Alloy (CRA) materials for pipelines. The technique of the present invention can also be used for larger scale structures (containers) fabricated from clad flat panels. Another application invo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com