Moulding element for a tyre mould comprising a porous area

一种模制元件、轮胎模具的技术,应用在生产所述模制元件领域,能够解决减小元件材料密度、机械负荷易损坏、易损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following description, substantially the same or similar elements will be denoted by the same reference numerals.

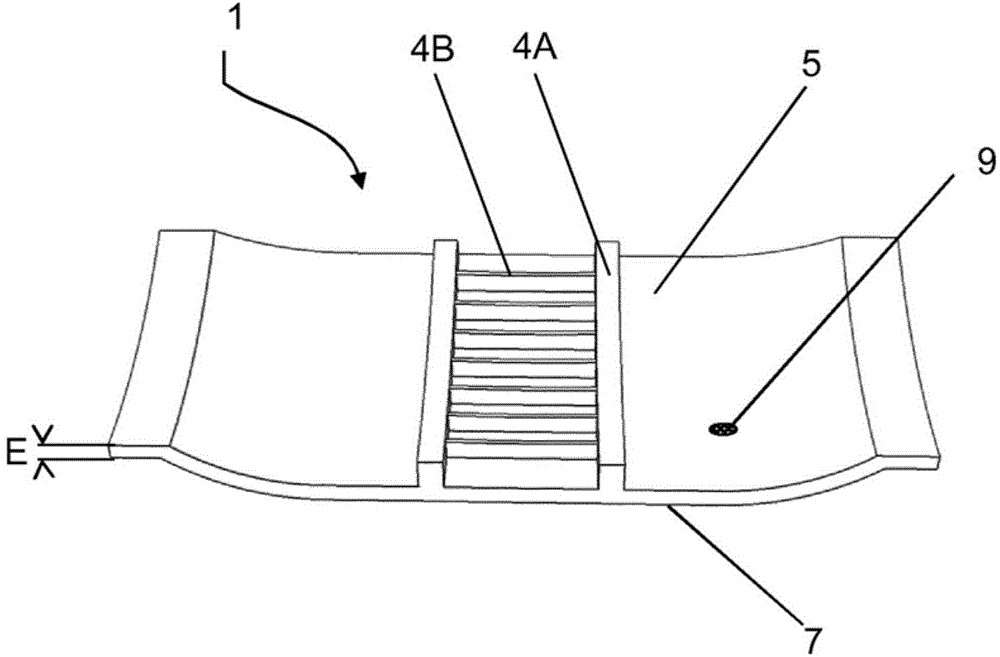

[0034] figure 1 is a perspective view of a molded element 1 made of metal powder fused together layer by layer. Said molding element comprises a body 3 and projections 4A, 4B protruding from said body 3 . In particular, among these protrusions, the strips 4A are distinguished from the sipe blades (blades) 4B which in this case are perpendicular to the strips 4A. A "strip" means a protrusion whose width is greater than or equal to 2 mm. The strips are intended to mold the grooves in the tread of the tyre. By "sipe blade" is meant a protrusion whose width is less than 2 mm. The sipe blade is intended for molding the sipe in the tread of a tyre.

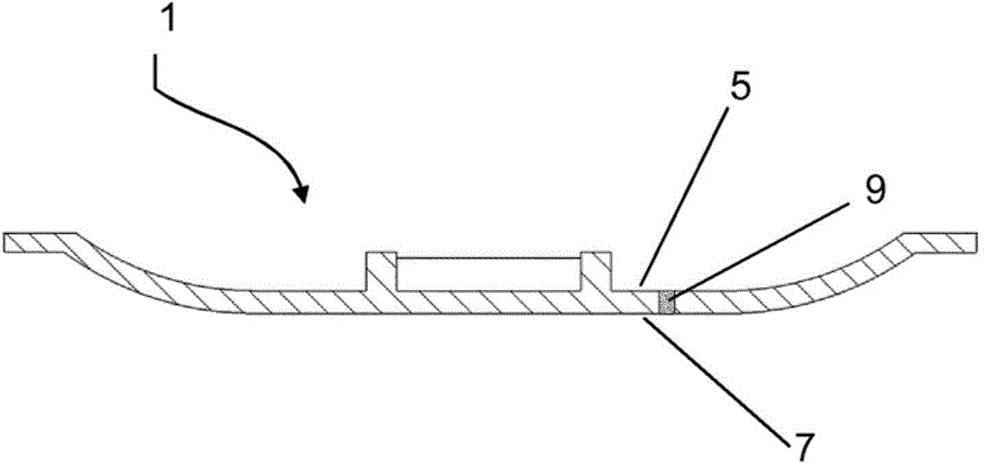

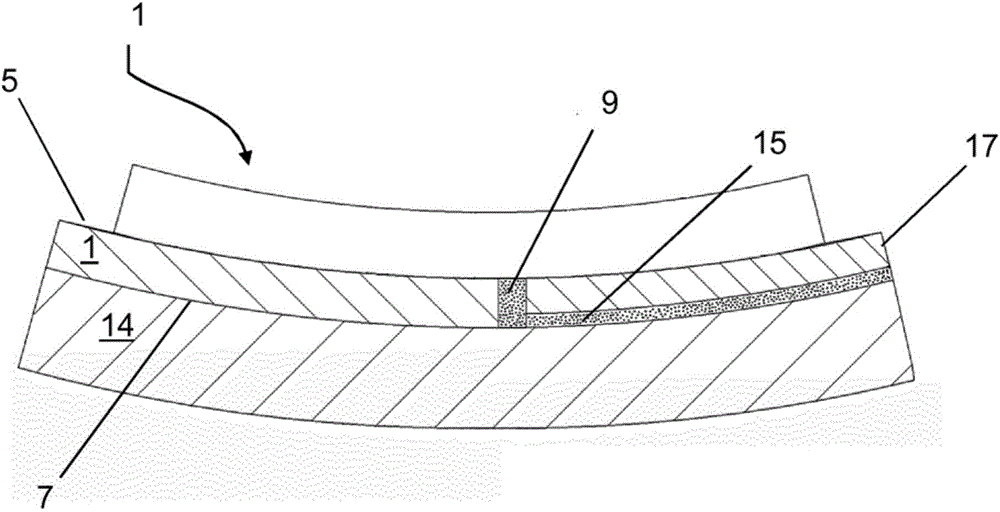

[0035] The body 3 also includes a first surface 5 and a second surface 7 opposite to the first surface 5 . The first surface 5 is intended for molding all or part of the tread surface of the tyre, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com