Tire manufacturing method and tire manufacturing line

A manufacturing method and production line technology, applied in the field of tire manufacturing, can solve the problems of tires of different sizes and difficult to form sizes at the same time, so as to improve the operation rate and reduce the storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, embodiments of the present invention will be described in detail.

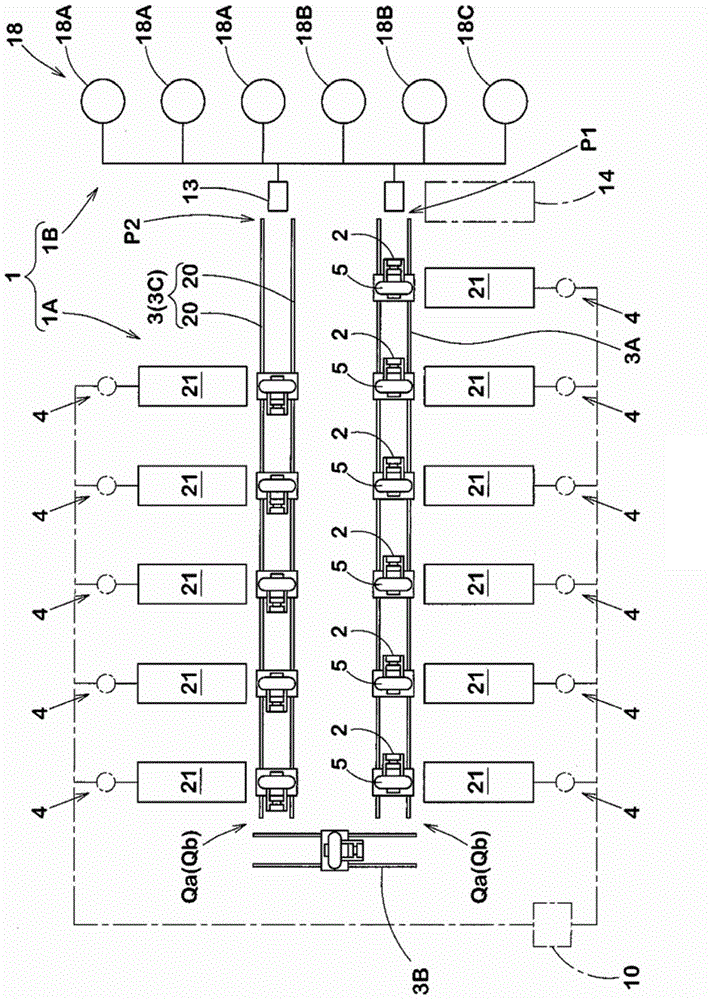

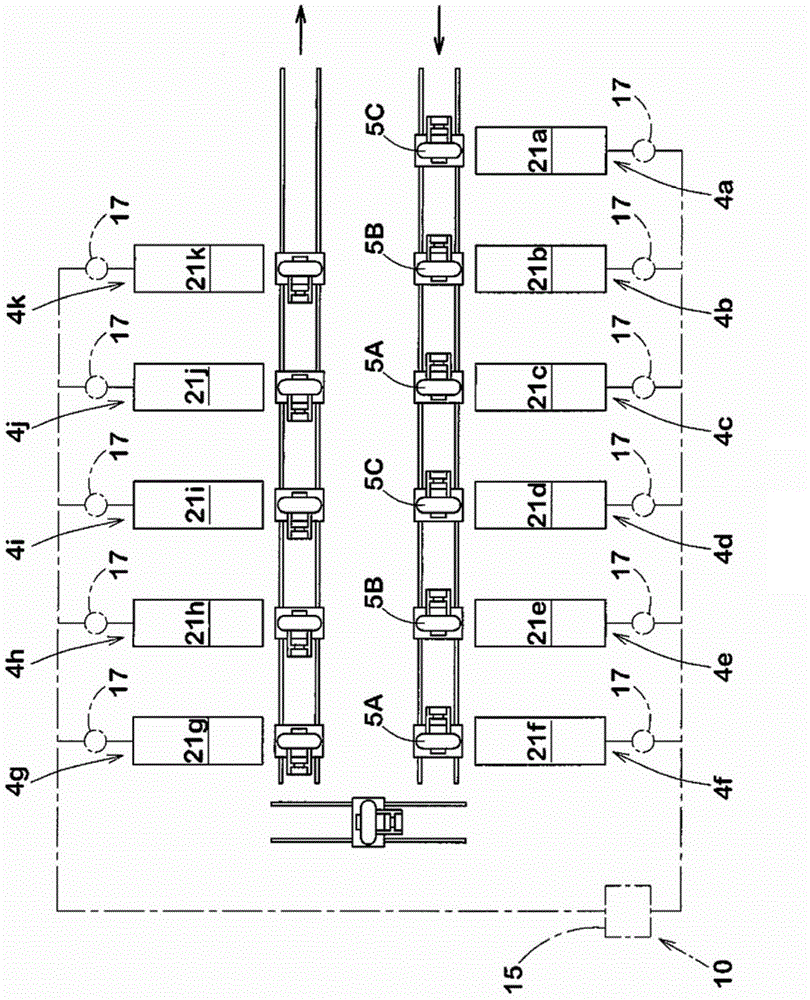

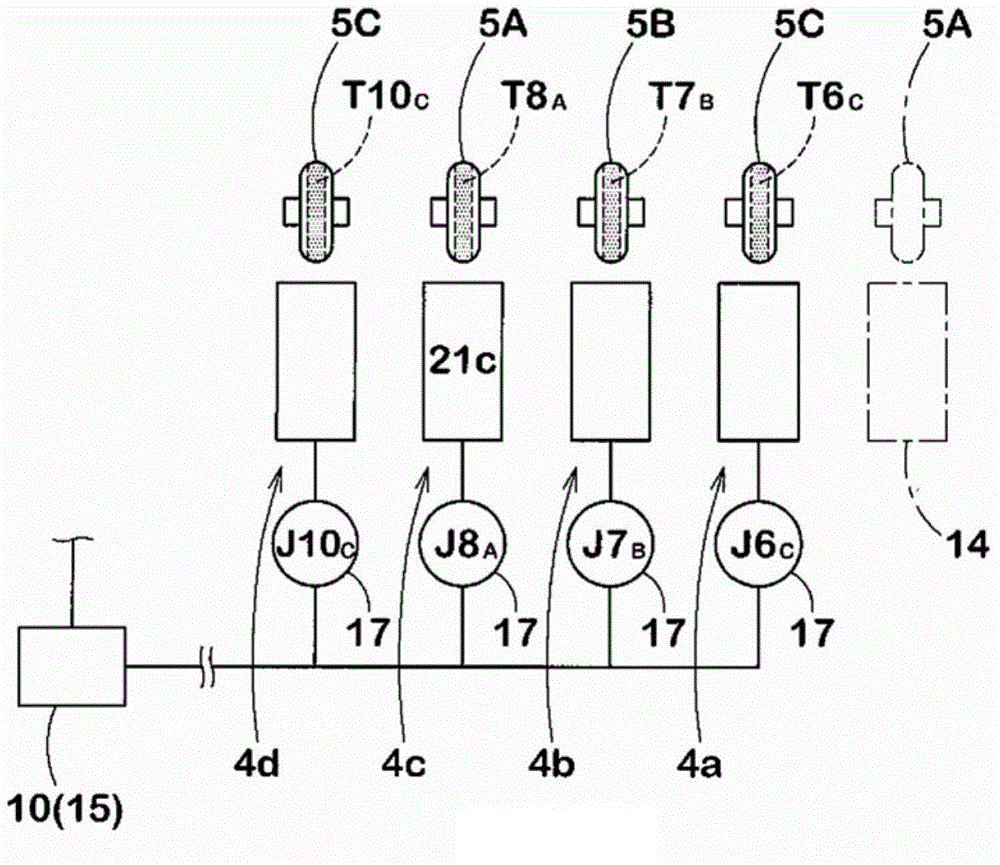

[0052] Such as figure 1 As shown, the tire manufacturing line 1 of the present embodiment includes a green tire forming line 1A and a tire vulcanizing line 1B.

[0053] The raw tire forming line 1A described above includes a rail 3 and a plurality (n) of work stations 4 arranged along the rail 3 . Then, the green tire forming process is performed in the green tire forming line 1A, and the tire component T is pasted on the outer surface of the rigid core 5 moving on the above-mentioned rail 3 in the order of the above-mentioned arrangement at each work station 4. This forms the green tire 6 .

[0054] In addition, the tire vulcanization line 1B has a plurality of vulcanization molds 18, and the vulcanization process is performed in the tire vulcanization line 1B, and the green tire 6 formed above is put into the vulcanization mold 18 together with the rigid core 5 for vulcanization molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com