Efficient steam food processer

A cooking machine and steam technology, applied in the field of kitchen utensils, can solve the problems of low utilization rate of steam and high temperature of the side wall of the steamer, achieve the effects of simple and beautiful appearance, improve utilization rate, and prevent excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

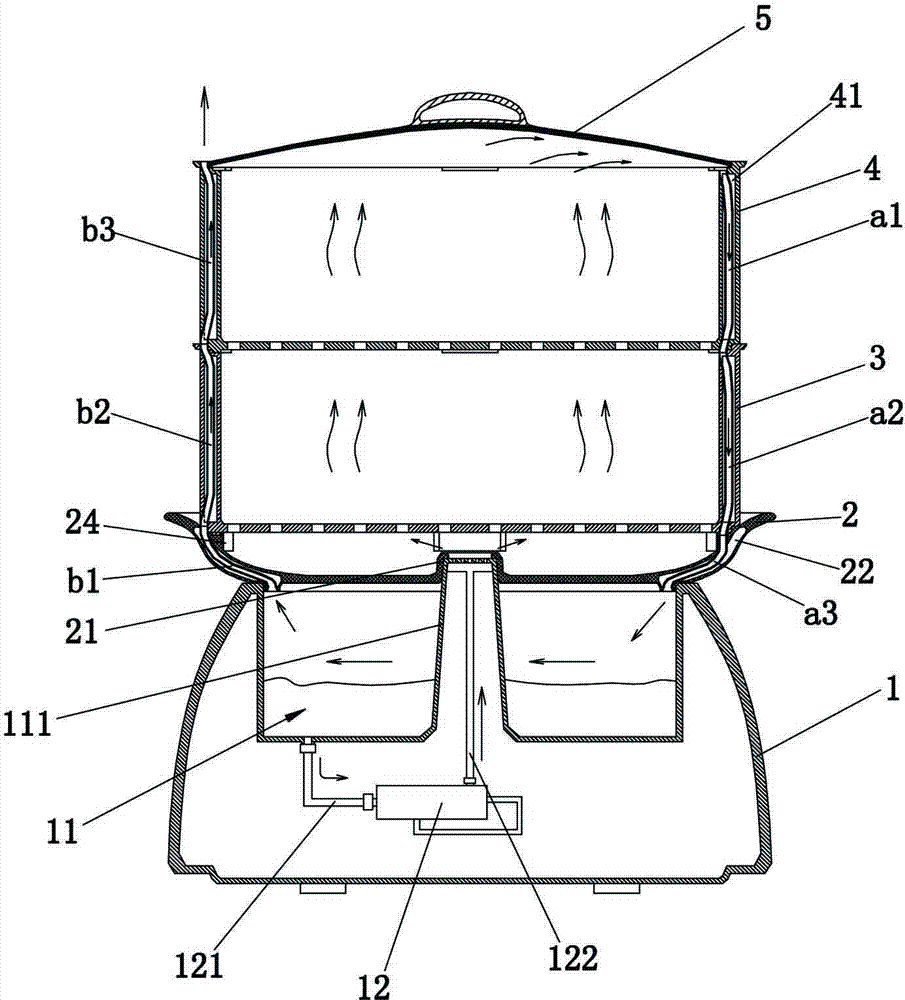

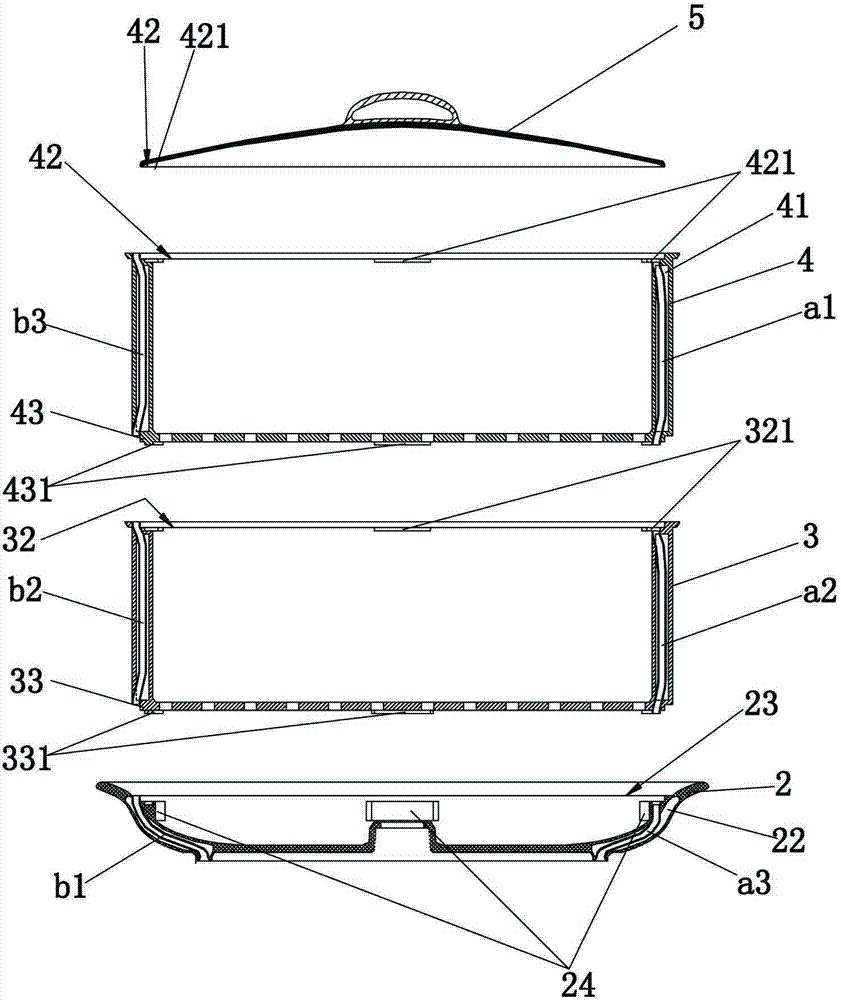

[0020] The specific embodiments of the present invention are described below with reference to the drawings.

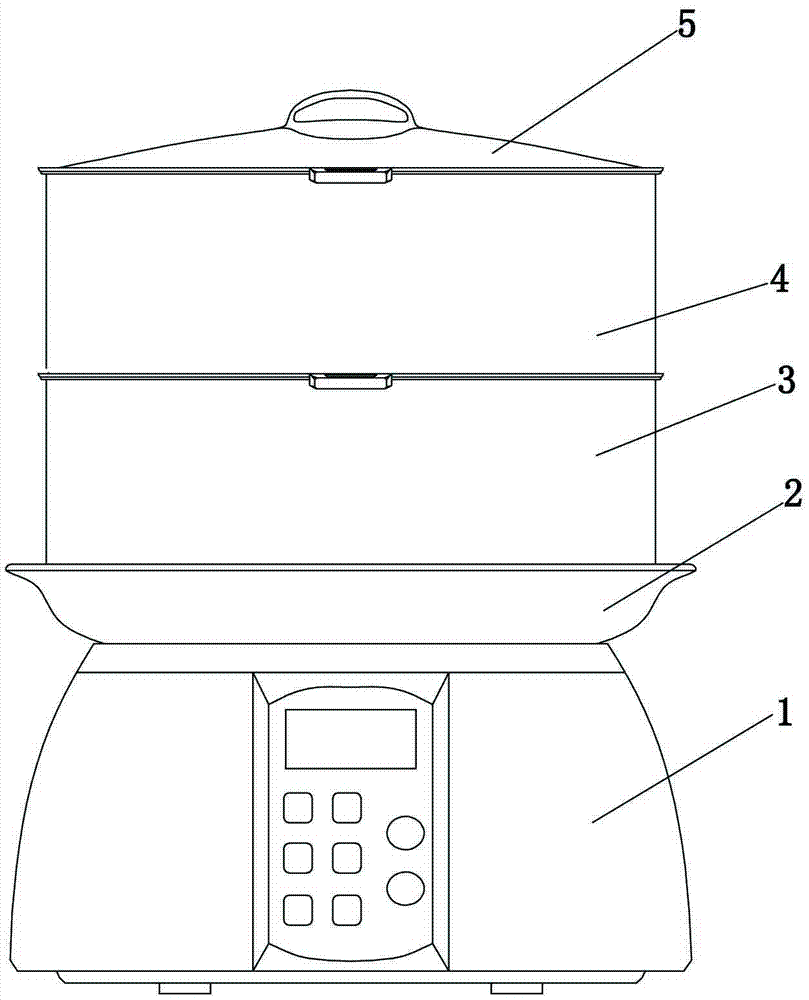

[0021] Such as figure 1 with figure 2 As shown, a steam cooking machine capable of improving steam utilization includes a heating base 1, a water receiving tray 2, a steamer 3, a steamer 4, and a pot cover 5 stacked in sequence. The heating base 1 is provided with a steam generating device 12 and its control circuit (not shown in the figure). The middle and upper part of the heating base 1 is provided with a water tank 11, and the middle position of the bottom of the water tank 11 bulges upward to form a sleeve 111. The upper end surface of the sleeve 111 is provided with a plurality of steam holes; the middle position of the bottom of the water receiving pan 2 bulges upwards to form a steam duct 21. When in use, the water receiving pan 2 is placed on the upper end surface of the heating base 1, and the steam pipe 21 is butted with the sleeve 111. The water in the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com