Novel environmental-protection paint dip-coating device

An environmentally friendly coating and dip coating technology, which is applied in casting molding equipment, parts of molding machines, metal processing equipment, etc., can solve the problems of reduced coating, complicated cleaning of coatings, spilled coatings, etc., and achieves easy operation, reduced labor intensity, and convenience cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

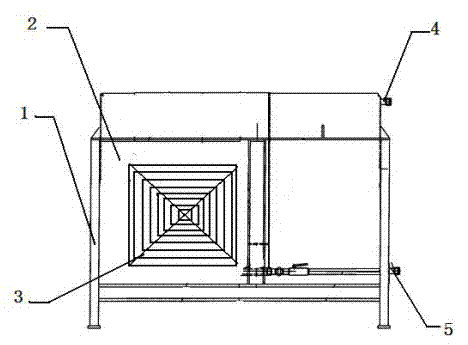

[0011] This embodiment provides a new type of environmental protection paint dipping device, characterized in that: the new type of environmental protection paint dipping device includes a support base (1), a dipping chamber (2), a filter (3), a paint inlet ( 4), paint export (5);

[0012] Wherein: the dipping chamber (2) is fixed on a support base (1), the top of the dipping chamber (2) is provided with a coating inlet (4), and the bottom of the dipping chamber (2) is provided with a coating outlet (5 ), the dipping chamber (2) is provided with a paint filter (3).

[0013] Its working process is: when the paint in the dipping chamber (2) decreases, the paint can be supplemented in real time through the paint inlet (4) to the paint in the dipping chamber (2), without manually replenishing the paint. Therefore, it is very convenient, the paint in the dipping chamber (2) will be discharged from the paint outlet (5), so the cleaning of the paint in the dipping chamber (2) is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com