Special equipment for conveying sand box into cooling channel

A special equipment and cooling channel technology, applied in the field of casting, can solve the problems of wire ropes being easily pulled, faulty production lines, low productivity, etc., and achieve the effect of reducing use costs and maintenance costs, improving production efficiency and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

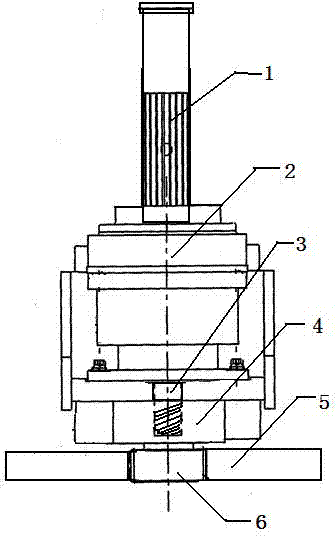

[0013] This embodiment provides a special equipment for sending the sand box into the cooling channel, which is characterized in that: the special equipment for sending the sand box into the cooling channel includes a drive cylinder (1), a mounting seat (2), a rotating shaft ( 3), guide wheel (4), rack (5), gear (6);

[0014] Among them: the driving cylinder (1) is placed on the mounting base (2), and a rotating gear (5) is arranged on the rotating shaft (3), and the rotating gear (5) meshes with the ratchet on the rack (6). When the cylinder (1) is driven, it drives the gear (6) installed on the rotating shaft (3) to rotate, and then under the action of the ratchets on the surfaces meshing with each other, the whole device can move along the ratchet extension direction of the rack (5).

[0015] The drive cylinder (1) is a drive cylinder.

[0016] The rotating shaft (3) is threadedly connected with the guide wheel (4).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap