Using method for hoop hole drilling device

A processing device and clamp technology, applied in the field of fixtures, can solve problems such as unqualified clamp 1 and difficulty in avoiding deformation of arc segment 13, etc., and achieve the effects of convenient operation, simple structure and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

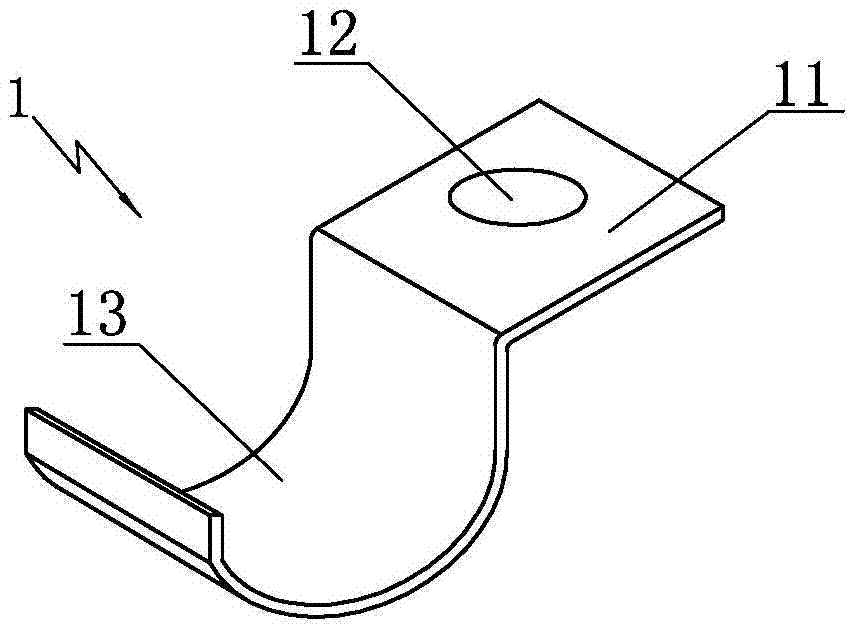

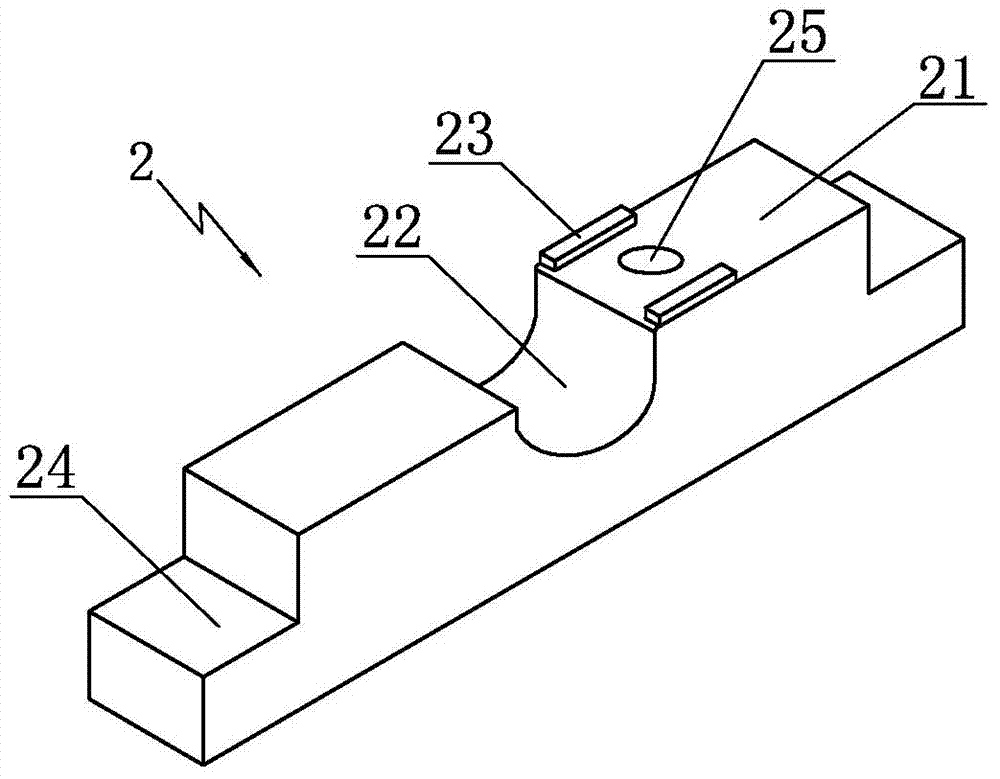

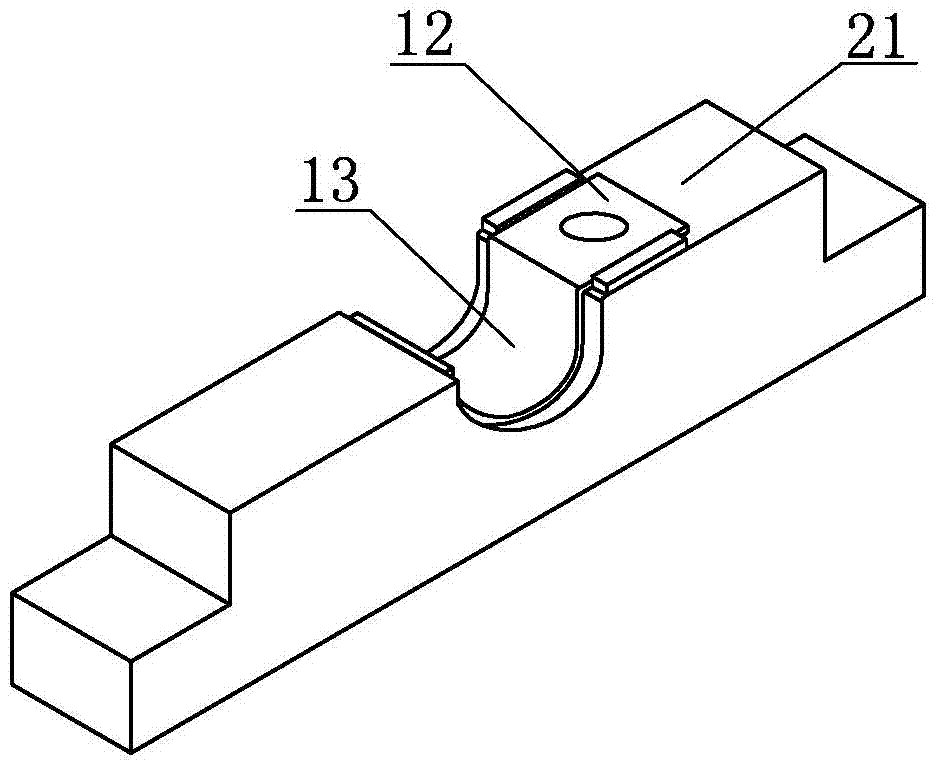

[0015] Such as Figure 1 to Figure 4 Shown, the present invention comprises die 2 and punch 3, and die 2 is rectangular block shape, and the width of die 2 is greater than the width of clamp 1, and the top surface 21 of die 2 has arc groove 22, uses Cooperate with the arc segment 13 of the clamp 1, there are positioning blocks 23 on both sides of the top surface 21, one end of the positioning block 23 is close to the edge of the arc groove 25, the height of the positioning block 23 is greater than the thickness of the clamp 1 and the positioning The distance between the blocks 23 is the same as the width of the clamp 1, which is conducive to positioning the horizontal section 11 of the clamp 1. On the top surface 21, a bore 25 is set between the positioning blocks 23. The size of the bore 25 is the same as that of the clamp. The circular ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap