Electric vehicle powertrain installation structure with profile structure

A technology of electric vehicles and powertrains, applied in the direction of electric power devices, power devices, control devices, etc., can solve the problems of easy resonance, heavy weight, inconvenient production, etc., achieve low strength, convenient production, and good anti-resonance effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

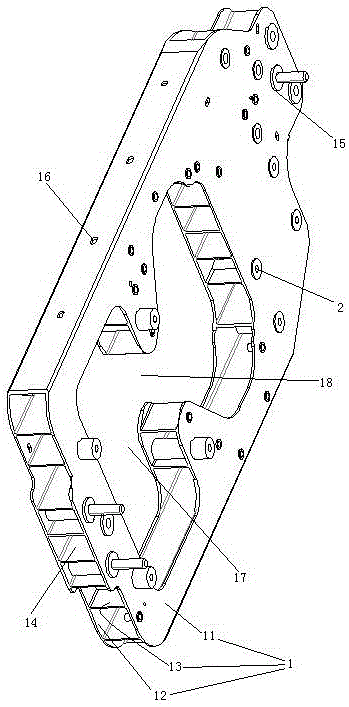

[0023] Embodiment one, see figure 1, an electric vehicle powertrain installation structure with a profile structure, including a bracket 1 . The bracket 1 is a plate-like structure. Bracket 1 is made of aluminum alloy profile. Bracket 1 is a linear structure extending perpendicular to the cross-sectional direction of the profile for making the bracket. The bracket 1 includes a panel 11 , a bottom plate 12 and a support bar 13 . The support bar 13 is a linear structure. There are 10 support bars 13. The support bar 13 is supported between the bottom plate 12 and the panel 11 . The panel 11 , the bottom plate 12 and the support bar 13 are integrally structured. Nine shock-absorbing channels 14 with open ends are formed between the base plate 12, the panel 11 and the support bar 13 (as long as there are two or more, there is an anti-resonance effect, if there is no one). Both ends of the bracket 1 along the extending direction of the support bar 13 are provided with hangin...

Embodiment 2

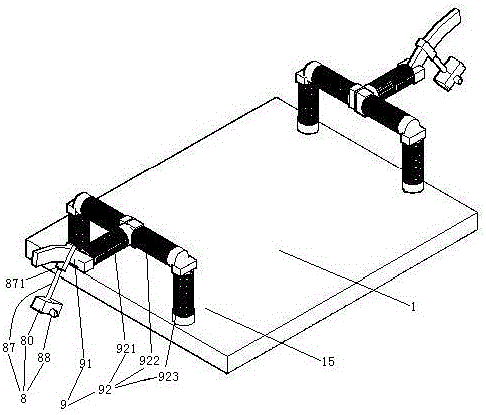

[0025] Embodiment two, see figure 2 , the bracket 1 is the same as that in the first implementation, and the bracket is only schematically drawn in the figure. The difference between the second embodiment and the first embodiment is that it further includes two suspension frames 9 and two coating heating mechanisms 8 .

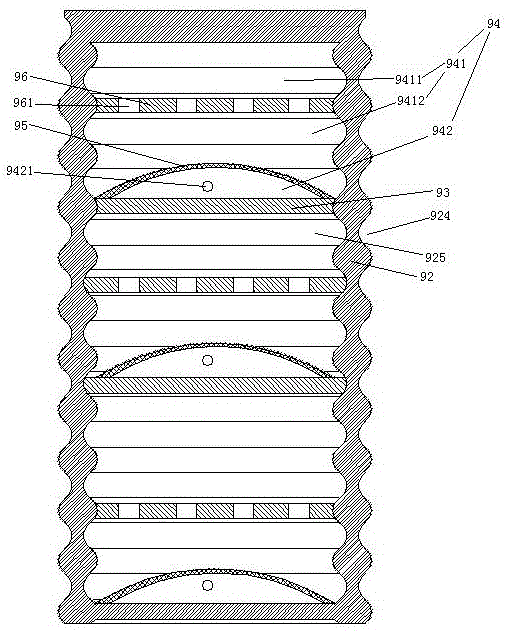

[0026] The two suspension frames 9 are connected to the two suspension parts 15 in one-to-one correspondence. The suspension frame 9 includes a connecting rod 91 and five shock absorbing rods 92 . The connecting rod 91 is an arc-shaped structure that arches upwards (of course, downwards is also possible). The five damping rods 92 are a horizontal damping rod 921 , two longitudinal damping rods 922 and two vertical damping rods 923 . One end of the connecting rod 91 is connected with one end of the transverse damping rod 921 . One end of the two longitudinal damping rods 922 and the other end of the transverse damping rod 921 are connected together. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com