Airbag sealing plug

An airbag sealing and airbag technology, applied in the field of bottle stoppers, can solve problems such as loss of seal, affecting the quality of objects in the bottle, and difficulty in ensuring the sealing effect of the bottle mouth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

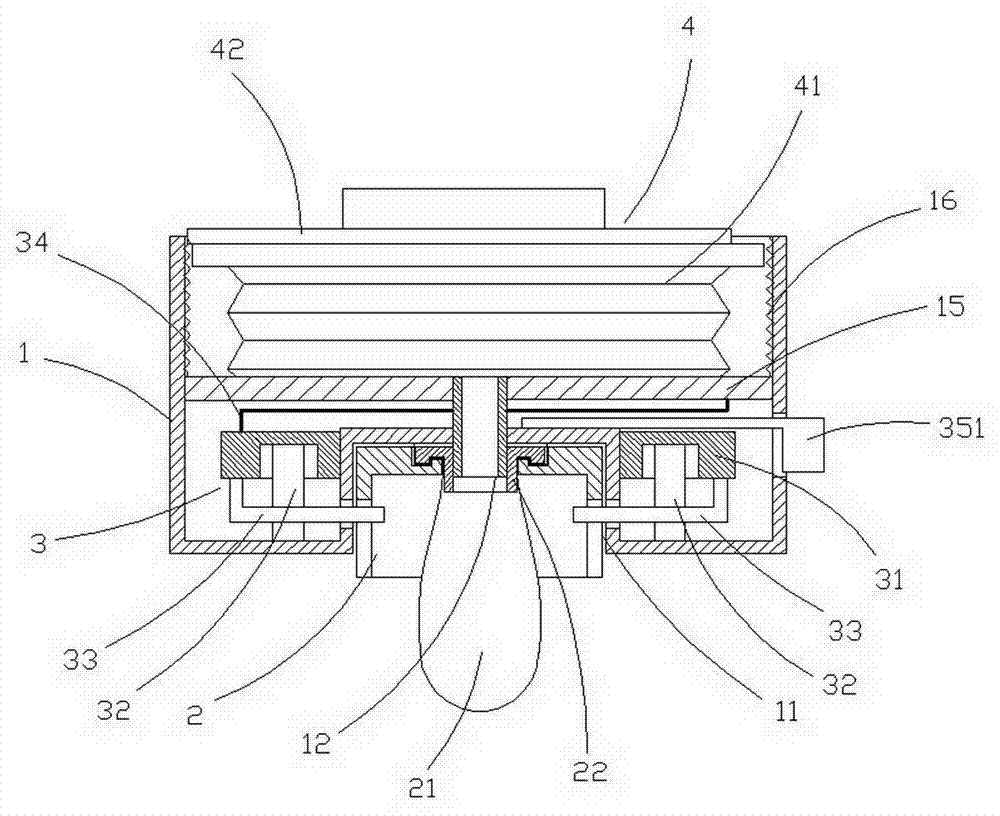

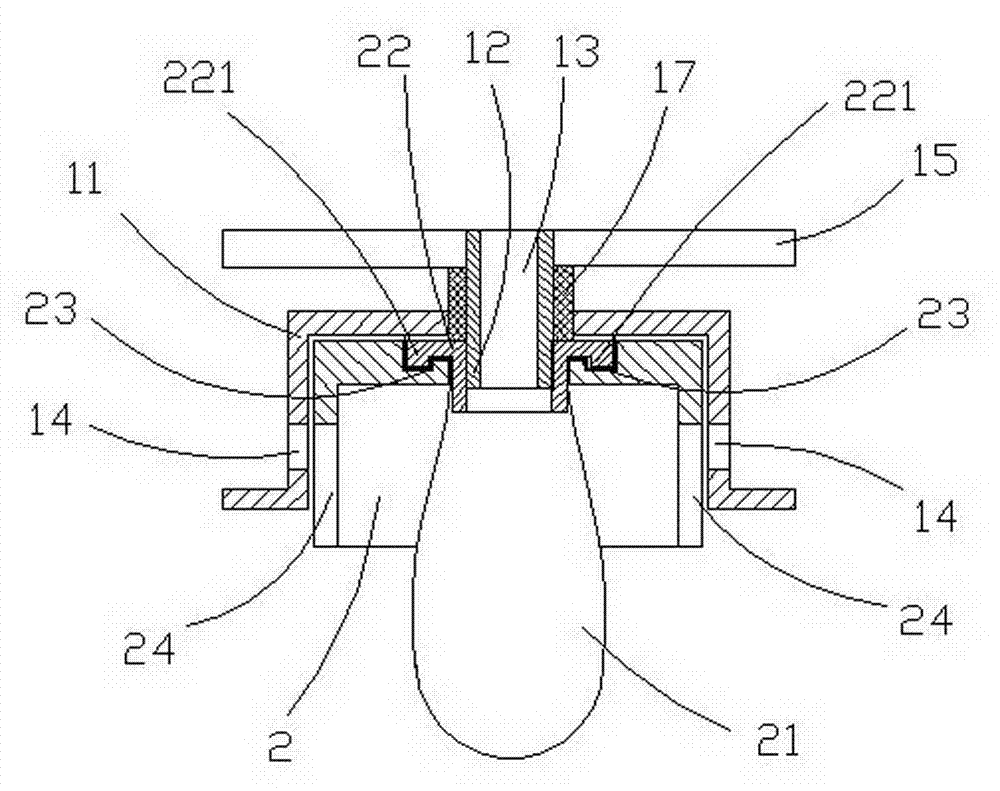

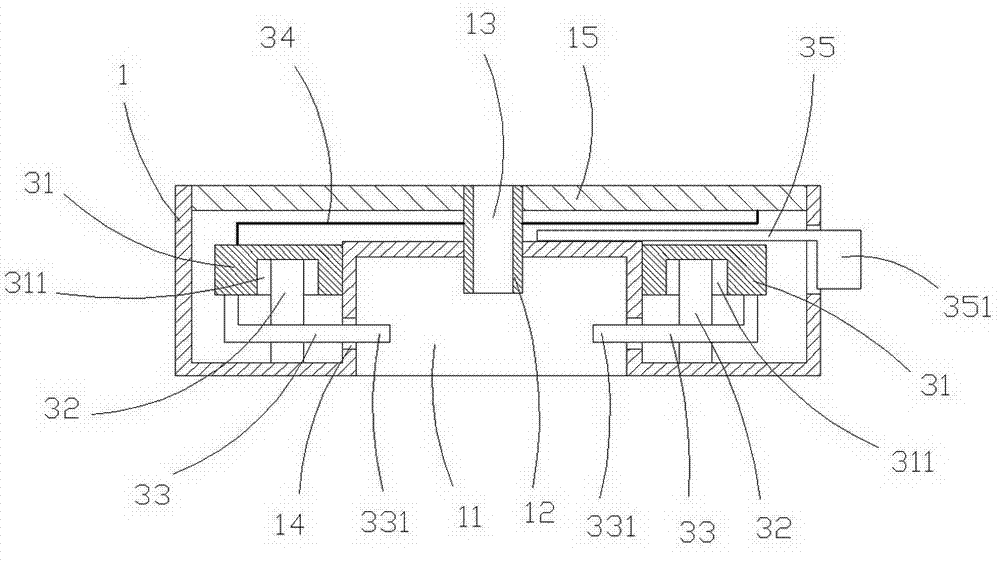

[0017] Such as figure 1 , 2 , 3, 4, and 6, an airbag sealing plug includes an outer shell 1, a clamping mechanism 3, an air pressure mechanism 4, and an airbag frame 2, and the center of the lower end surface of the outer shell is provided with an inwardly recessed bottle mouth accommodating groove 11. The through hole 13 at the bottom of the accommodating tank extends outwards to an interface 12, the air nozzle 22 of the airbag frame 2 is inserted into the mouth of the airbag 21, and the outer snap ring 221 snaps the edge of the mouth of the airbag 21 into the slot 23 of the airbag frame , the gas nozzle 22 is threadedly connected with the interface 12, the driving disc 31 of the clamping mechanism 3 is sleeved on the outer wall of the inwardly protruding accommodating groove 11, and one end of the three circumferentially arranged claws 33 is clamped on the driving disc 31, The other buckle end 331 is stretched in the lead-out hole 14 of the side wall of the accommodating gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com