Bonding layer material containing active element for thermal barrier coating

A technology of active elements and thermal barrier coatings, which is applied in the development and application of new materials, can solve the problems of destroying thermal barrier coatings, etc., so as to improve the service life, improve the resistance to high temperature oxidation and corrosion, and improve the ability to resist high temperature oxidation and corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

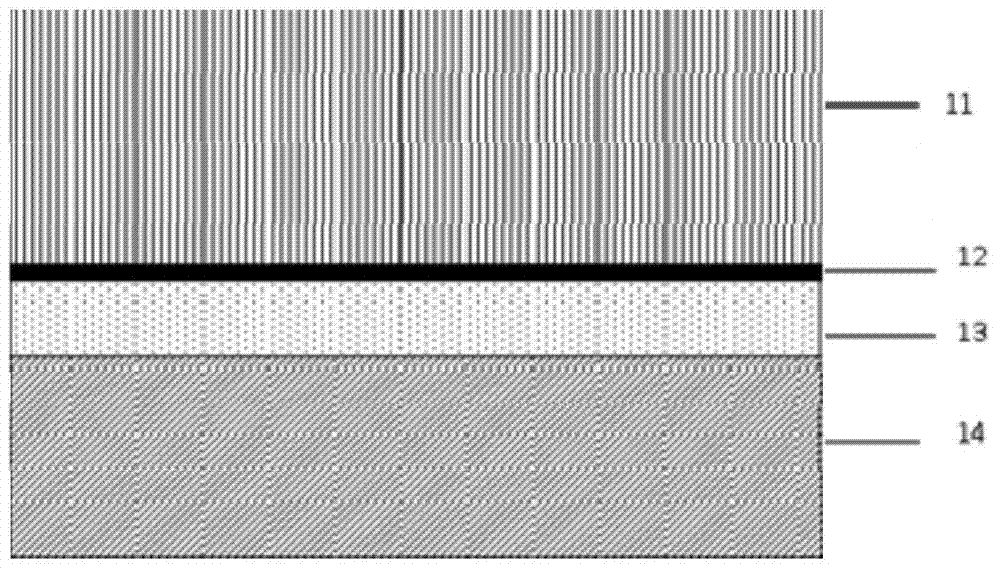

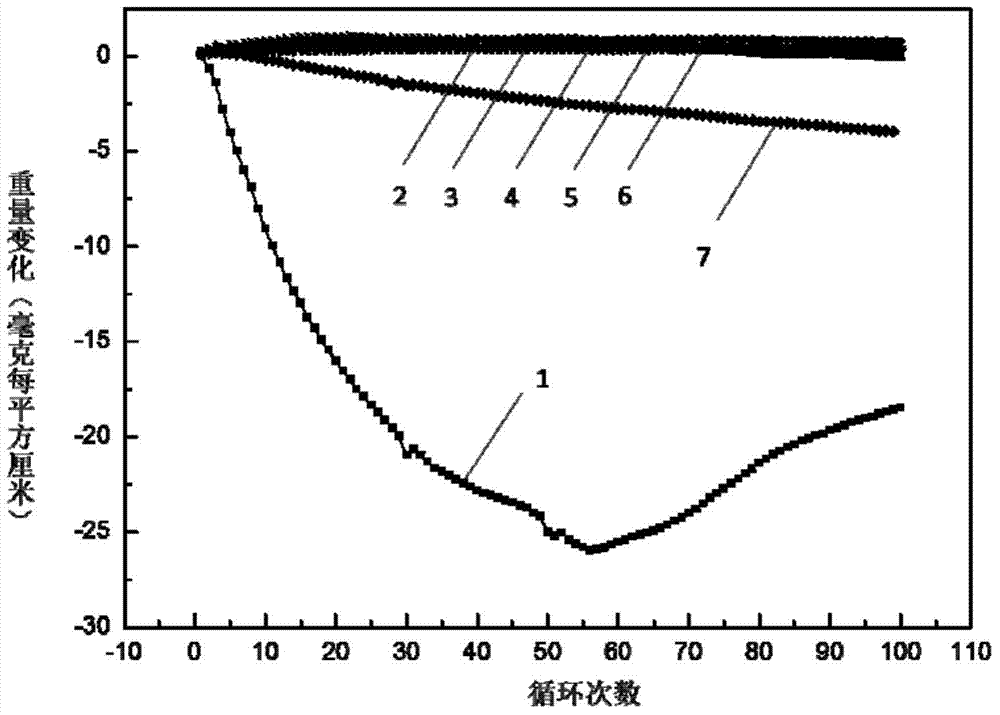

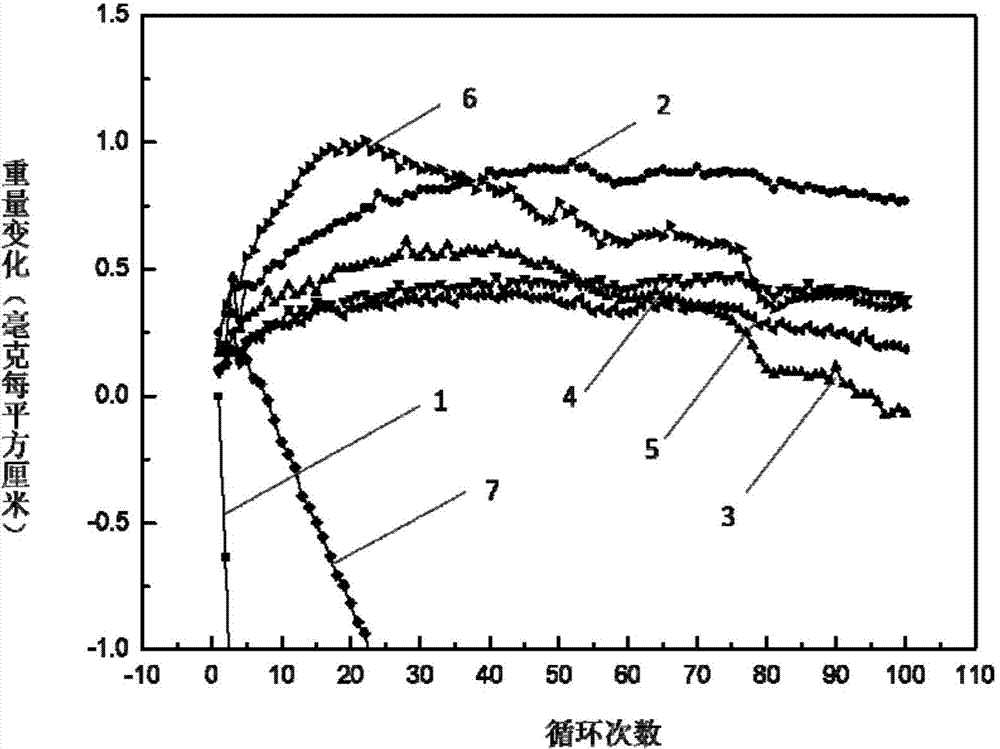

[0042] The invention proposes a novel bonding layer material containing an active element for thermal barrier coatings, and a cobalt-nickel-based high-temperature alloy material for the bonding layer of thermal barrier coatings of high-temperature parts of turbine blades. Further elaborate as follows by embodiment:

[0043] Bonding material of the present invention is made of basic component and added component; The atomic percentage of described matrix component and each component is as follows:

[0044] Co: Bal. (surplus),

[0045] Ni: 24at%-34at%,

[0046] Cr: 16at%-27at%, more preferably 16at%-22at%,

[0047] Al:9at%-21at%, more preferably 9at%-16at%,

[0048] The purity of each of the above matrix components is above 99.90%.

[0049] Add any one of the following ingredients and the atomic percentage is as follows:

[0050] Sc: 0.05at%-2at%, better 0.05at%-0.5at%, most suitable 0.05at%-0.2at%;

[0051] La: 0.05at%-2at%, better 0.05at%-0.5at%, most suitable for 0.05at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com