Method for preparing high-temperature-oxidation-resistant ZrB2-Al2O3/MCrAlY metal ceramic coating through rapid laser cladding

A zrb2-al2o3, cermet coating technology, applied in metal material coating process, coating and other directions, can solve the problems of reduced growth rate, difficult to repeat preparation, single crystal MCrAlY powder and high cost of coating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Sandblasting roughening: use 240# sandpaper for grinding, and then use white corundum to roughen the superalloy workpiece (white corundum particle size: ~120μm, sandblasting pressure: 0.2~0.8MPa), and then use The mixture of acetone and ethanol is ultrasonically cleaned, the workpiece is thoroughly dried, and then the workpiece is fixed on the rotary table.

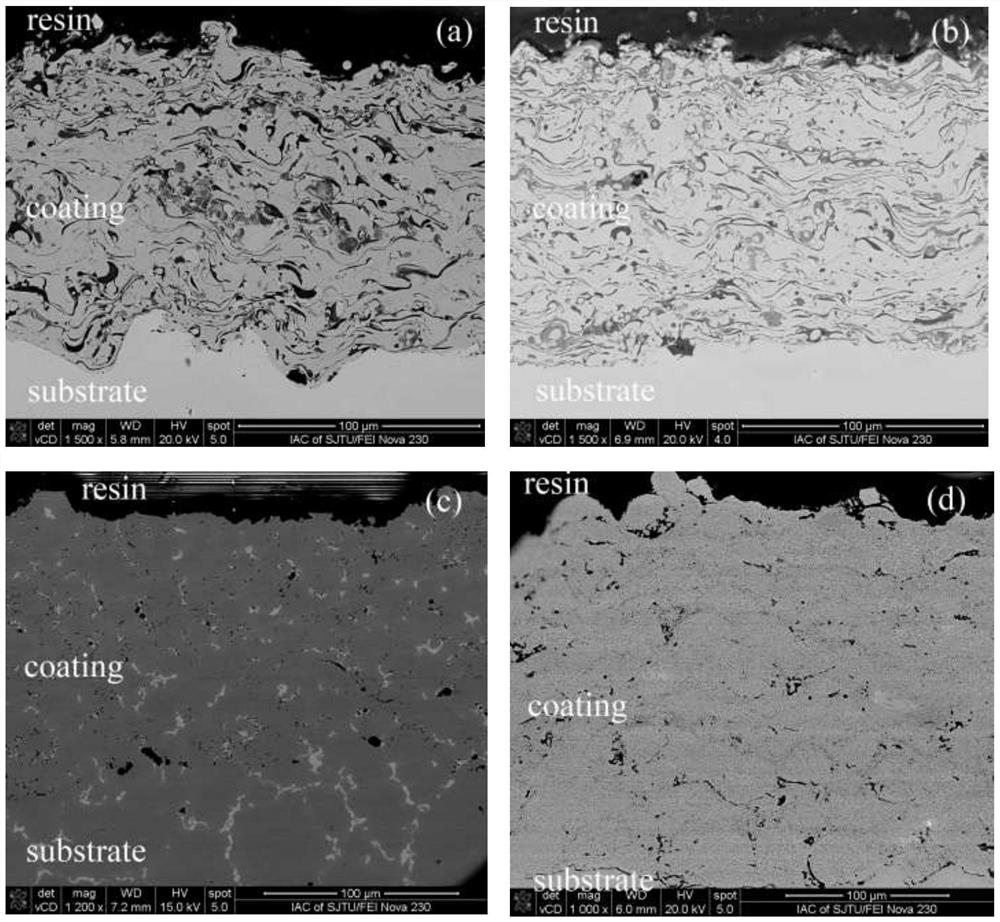

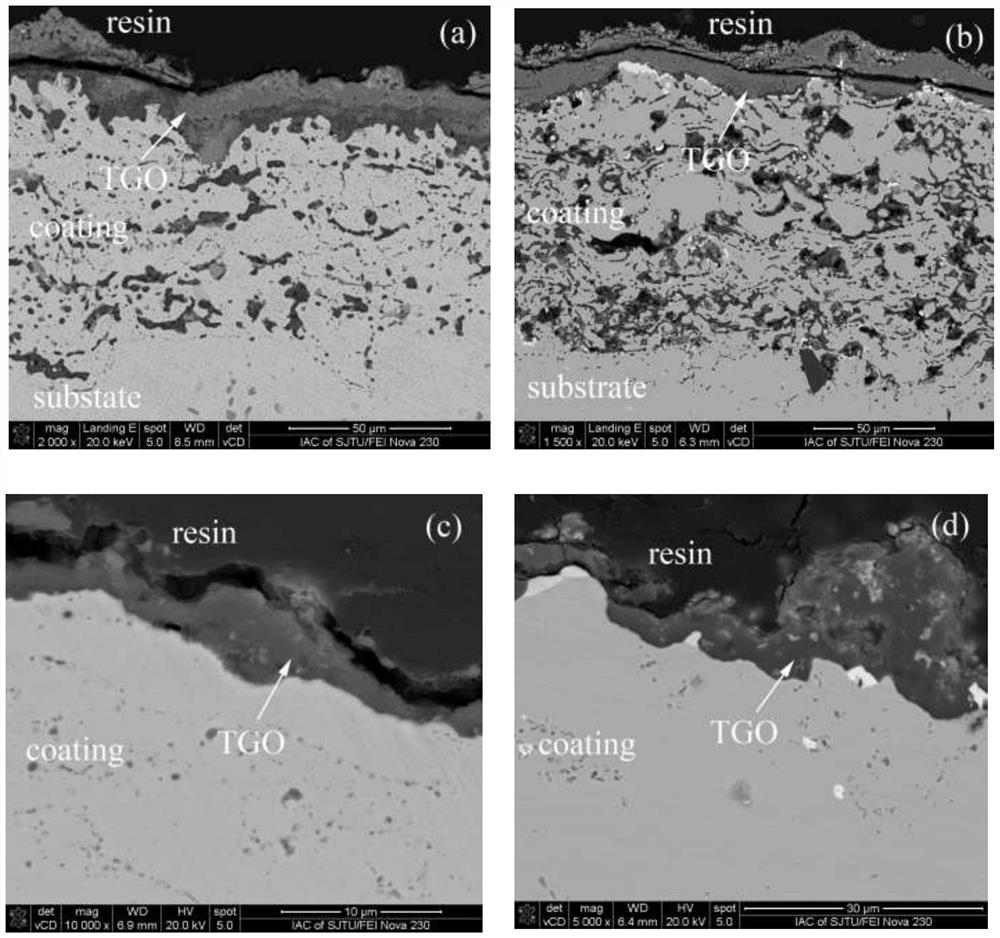

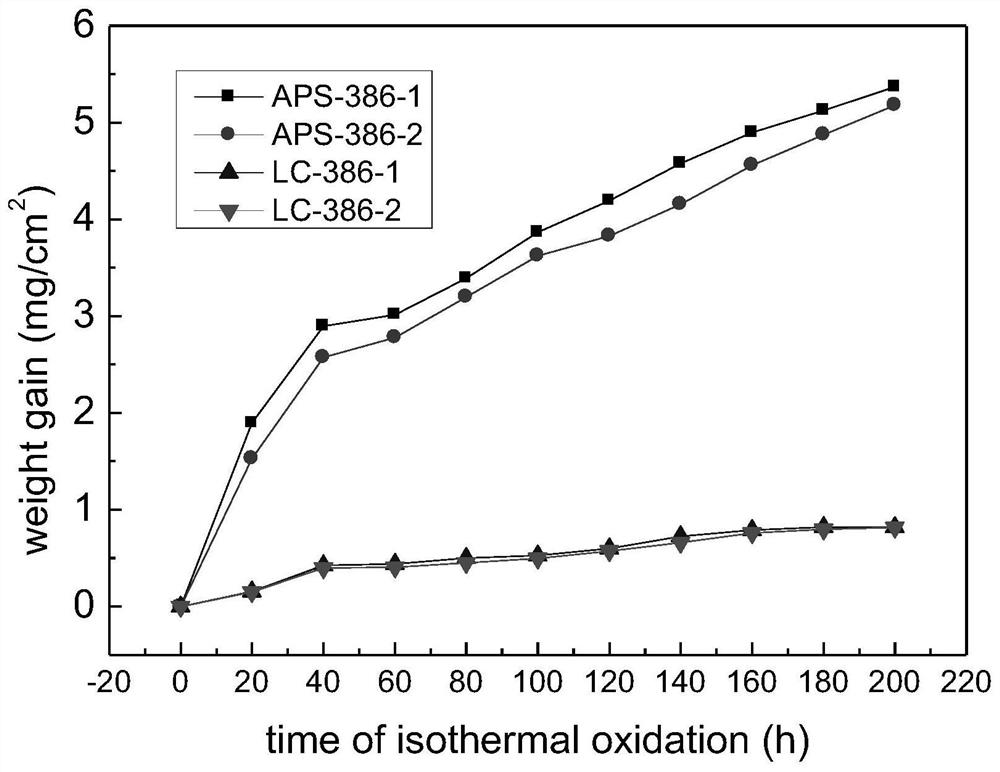

[0026] (2) Coating preparation: adopt synchronous powder feeding, laser power is 2000~3000W; powder feeding gas N 2Or Ar pressure is 0.3~0.6MPa, powder feeding gas N 2 Or the flow rate of Ar is 0.1~1m 3 / h, the powder feeding amount is 5-100g / min; the beam scanning moving speed is 250-650mm / s; the circular spot diameter is 3.5mm; the overlap rate of passes is about 45%; the number of cladding layers is 2-20 , the thickness of the cladding coating is 100 μm to 1000 μm. ZrB 2 -Al 2 o 3 / NiCoCrAlHfYSi cermet powder is firstly mixed by mechanical ball milling method, and then granulated by spray dryer, ZrB 2...

Embodiment 2

[0029] (1) Sandblasting roughening: Grinding with 240# sandpaper, and then using white corundum to roughen the superalloy workpiece (white corundum particle size: ~120μm, sandblasting pressure: 0.2~0.8MPa), and then using The mixture of acetone and ethanol is ultrasonically cleaned, the workpiece is thoroughly dried, and then the workpiece is fixed on the rotary table.

[0030] (2) Coating preparation: adopt synchronous powder feeding, laser power is 2000~3000W; powder feeding gas N 2 Or Ar pressure is 0.3~0.6MPa, powder feeding gas N 2 Or the flow rate of Ar is 0.1~1m 3 / h, the powder feeding amount is 5-100g / min; the beam scanning moving speed is 250-650mm / s; the circular spot diameter is 3.5mm; the overlap rate of passes is about 45%; the number of cladding layers is 2-20 , the thickness of the cladding coating is 100 μm to 1000 μm. ZrB 2 -Al 2 o 3 / NiCoCrAlHfYSi cermet powder is firstly mixed by mechanical ball milling method, and then granulated by spray dryer, ZrB ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com