Circular heald frame

A circulating and heald frame technology, which is applied in healds, textiles, textiles and papermaking, etc., can solve the problems of loss and high energy consumption of the motor driving the heald frame, and achieve energy saving and high strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

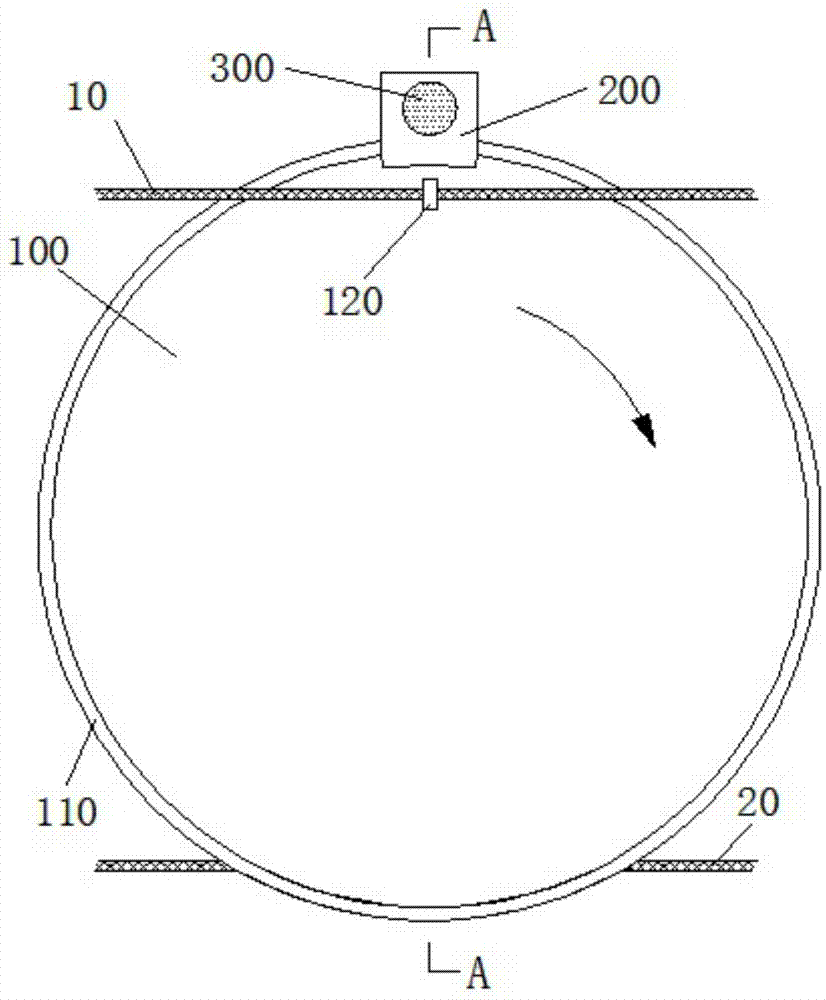

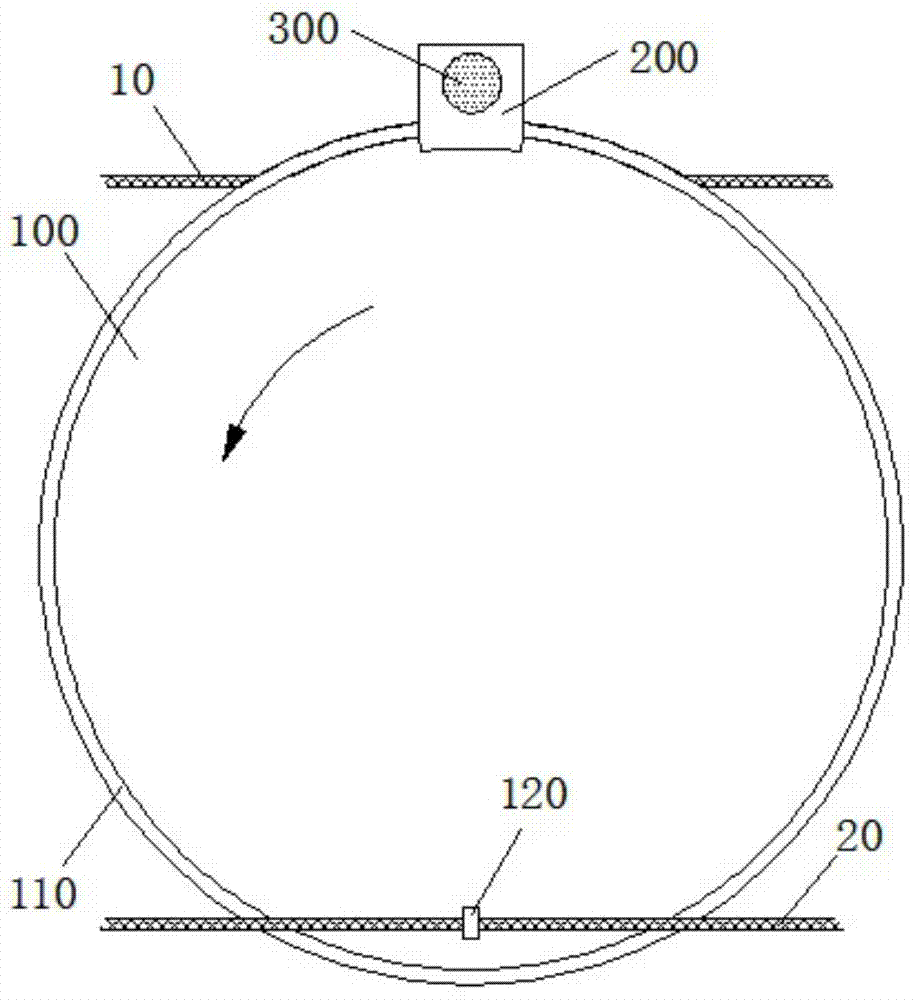

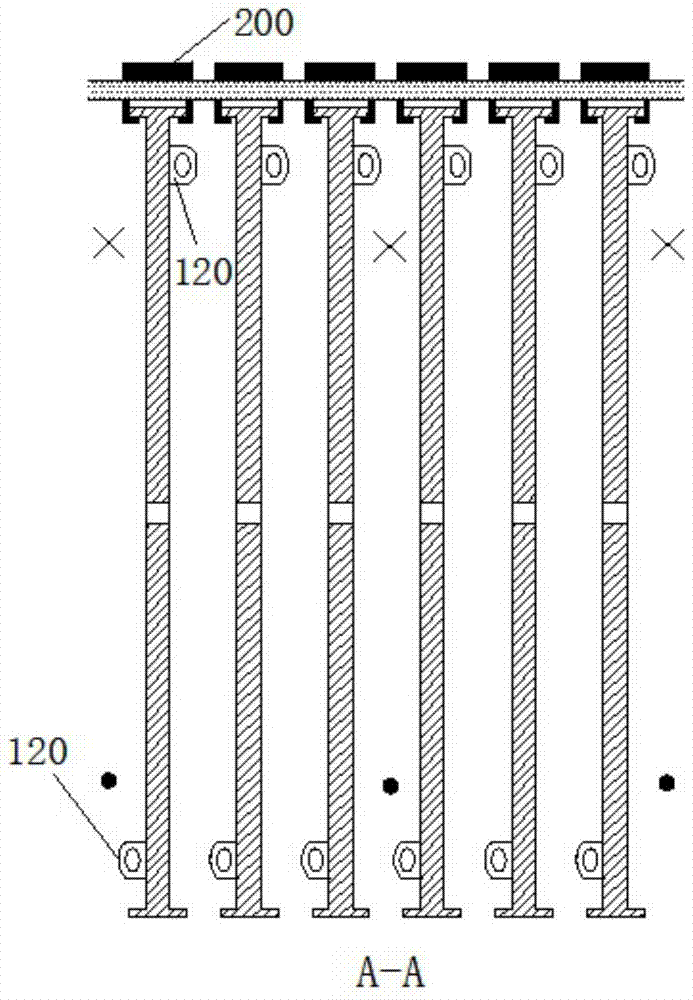

[0019] refer to figure 1 , figure 2 and image 3 , in the present embodiment, the circulating heald frame includes heald rings 120 passing through the warp yarns, and the heald rings 120 are respectively rotatably connected to the two sides of a driving disk 100, and the heald rings 120 distributed on both sides are pressed according to the driving disk 100 The center of the drive disc 100 is arranged symmetrically, the edge of the drive disc 100 is provided with a guide rail 110 or a groove, and one side of the drive disc 100 is slidably arranged in a drive clamp seat 200, and the drive clamp seat 200 is provided with a The guide rail 110 is a slide rail that is slidably matched, and the driving clamp seat 200 is provided with a driving structure that drives the driving disk 100. The driving disk 100 is arranged in an array along the axis to form a heald frame that makes the warp yarns 10, 20 layered up and down. Refer to image 3 , the heald loops 120 on the same driving ...

Embodiment 2

[0022] In another embodiment, on the basis of Embodiment 1, induction coils 400 are provided on both sides of the drive disc 100, magnets that cooperate with the induction coils 400 are provided in the heald ring 120, and the induction coils 400 Coil 400 makes the axis of described heald ring 120 point to the moving direction of warp yarn 10,20, and the axis of described heald ring 120 points to the moving direction of warp yarn 10,20 all the time, can keep the ring hole of heald ring 120 and warp yarn 10,20 to keep Proper distance, less friction. The magnet is an annular permanent magnet coaxially arranged with the heald ring 120, Figure 5 , the enlarged picture in the circle is the magnetic field direction diagram of the ring permanent magnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com