Inclined shaft pavement structure and laying method

A pavement structure and pavement laying technology, which is applied in the direction of roads, roads, special pavements, etc., can solve the problems of long paving period, impractical and long construction period of inclined well pavement, and achieve low cost of concrete pavement, simple laying method and short construction period short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

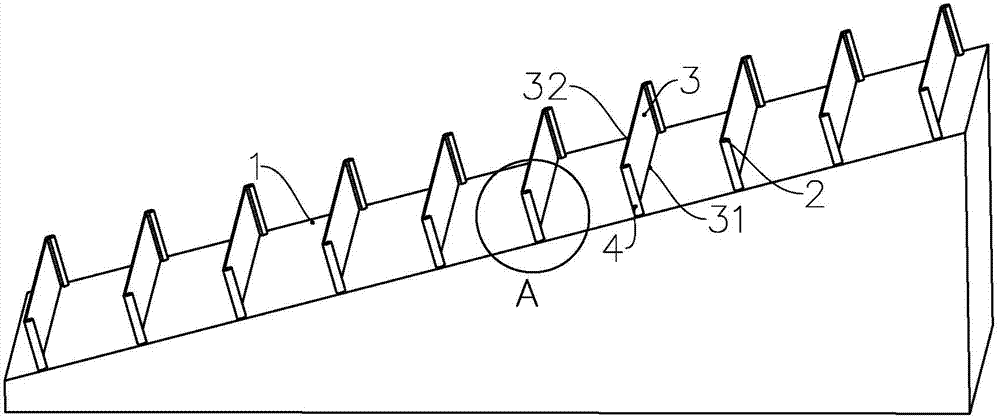

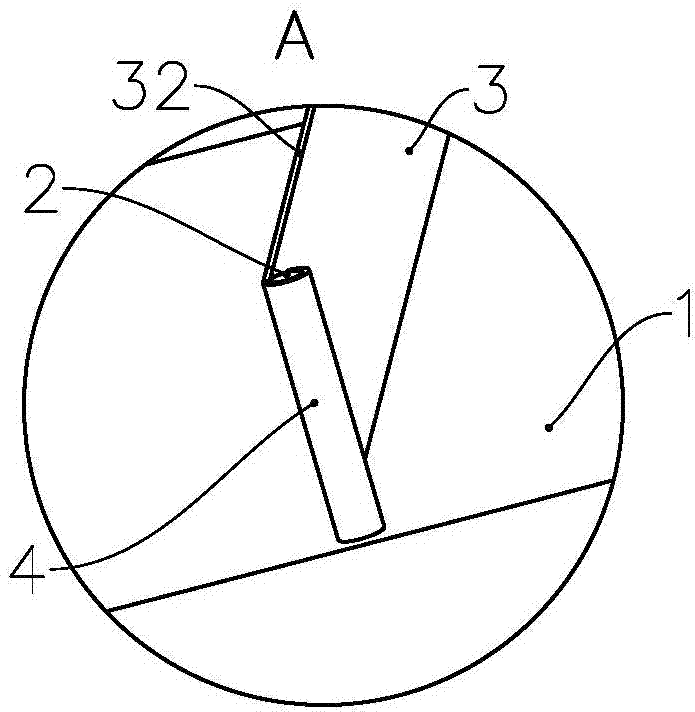

[0017] Example of inclined shaft pavement structure

[0018] Such as figure 1 As shown, the embodiment of the inclined shaft pavement structure of the present invention includes a fixed column 2, a connecting belt 3 and a concrete layer (not shown), wherein the inclined shaft ground 1 forms a certain angle with the horizontal plane and extends along this angle, and two rows of fixed columns 2 They are respectively arranged on both sides of the road surface at the same interval, preferably the distance between the connecting columns is between 20cm and 40cm, for example, 30cm. A part of the fixed column 2 is inserted below the ground 1, and the fixed column 2 is set to be perpendicular to the ground 1, so that the fixed column 2 is firmly fixed on the ground 1, and the connecting belt 3 connects a pair of roads respectively located on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com