Expansion compensation connecting pipe fitting

A technology for connecting pipe fittings and pipe fittings, applied in the direction of adjustable connections, pipes/pipe joints/pipe fittings, pipe components, etc., which can solve the problems of poor safety and reliability of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

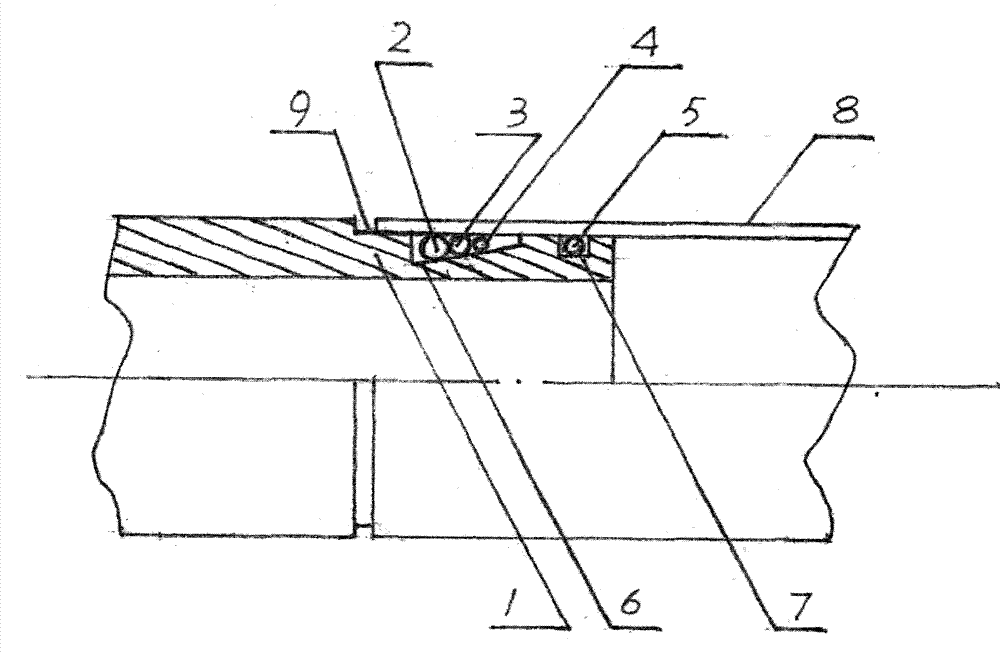

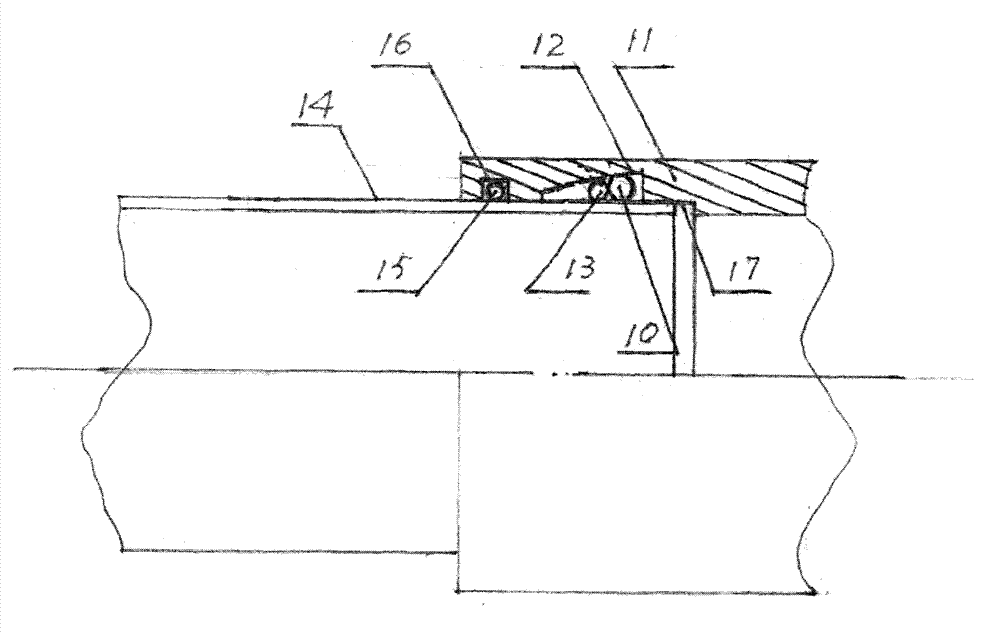

[0011] 1. Installation of plug-in telescopic compensation pipe fittings

[0012] Put the thrust rubber ring 2, steel ball ring 3, and positioning rubber ring 4 on the conical inner groove 6 of the insert 1 in sequence. Since the inner diameter of the positioning rubber ring 4 is smaller than the bottom diameter of the conical inner groove 6, Therefore, the elastic contraction force of the apron presses the steel ball ring 3 against the thrust apron 2 under the action of the slope of the conical inner groove 6, so that the steel ball ring 3 is sandwiched by the thrust apron 2 and the positioning apron 4 holding. The outer diameters of the thrust rubber ring 2, the steel ball ring 3 and the positioning rubber ring 4 placed on the conical inner groove 6 are respectively larger, slightly smaller and smaller than the inner diameter of the connecting pipe 8, and the inner diameter of the sealing rubber ring 5 is smaller than that of the circular ring The bottom diameter of inner gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com