Multi-scale print defect detection method based on random forest

A defect detection and random forest technology, applied in image data processing, instrumentation, computing, etc., to achieve the effect of low space complexity, reducing the number of inspections, and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

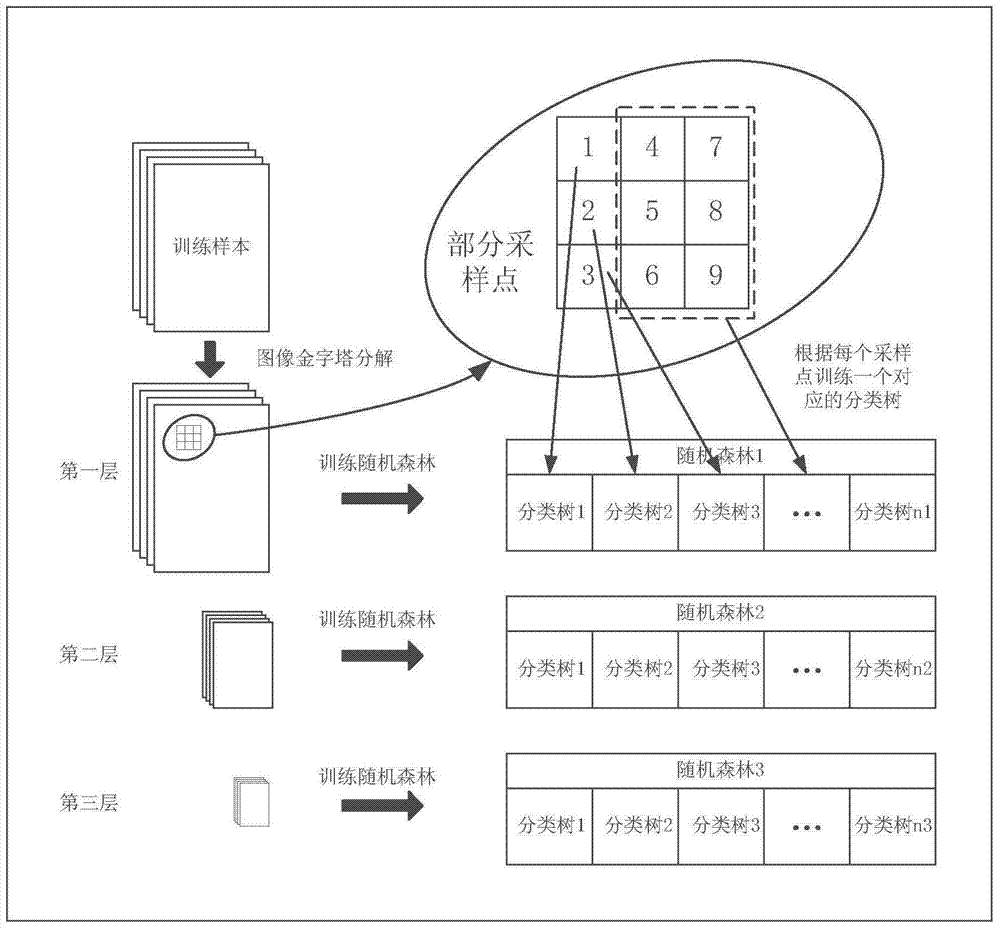

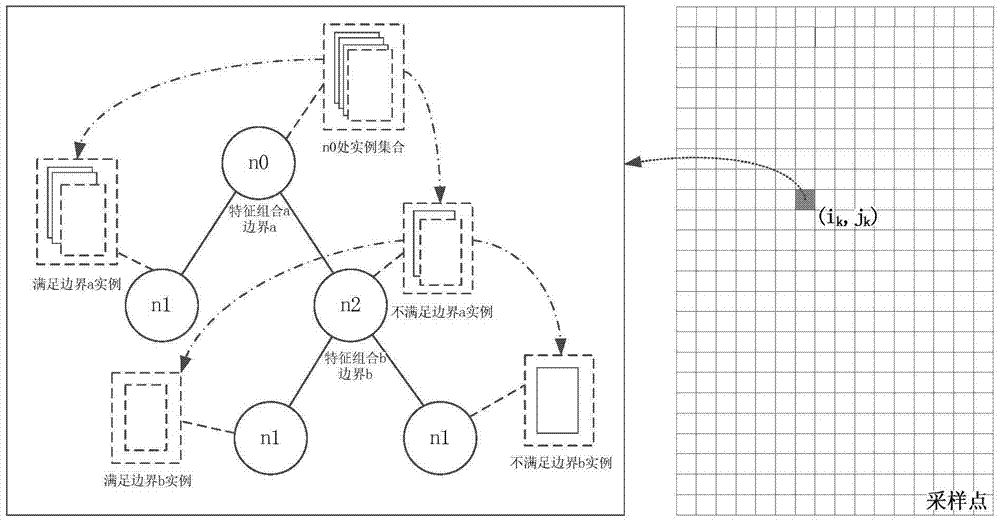

[0034] The invention is a random forest-based multi-scale defect detection method for printed matter. A certain number of qualified printed matter images that have been aligned are input to form a training sample. After the setting of the detection area, the generation of defect detection points and the multi-scale representation of the training sample image , Collect its cross-channel binary features for each defect detection point at each scale, and then train the random forest to generate a random forest defect detection model for each defect detection point at multiple scales; after having the model, given For the test image, first generate a multi-scale representation, and then apply the trained random forest defect detection model at each scale to judge whether there is a defect at the defect detection point, and perform multi-scale screening and synthesis of the defect detection point, and finally generate the detection effect .

[0035] Below in conjunction with embodi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap