Three-dimensional encapsulation surface antenna capable of achieving gap embedding amplitude calibration

A three-dimensional packaging, amplitude calibration technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

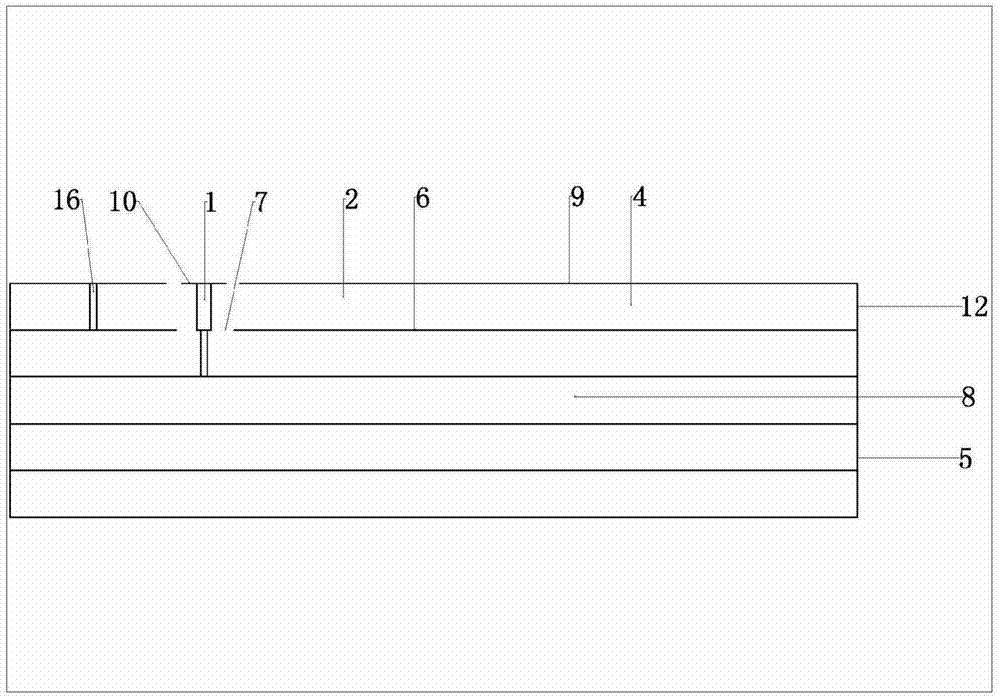

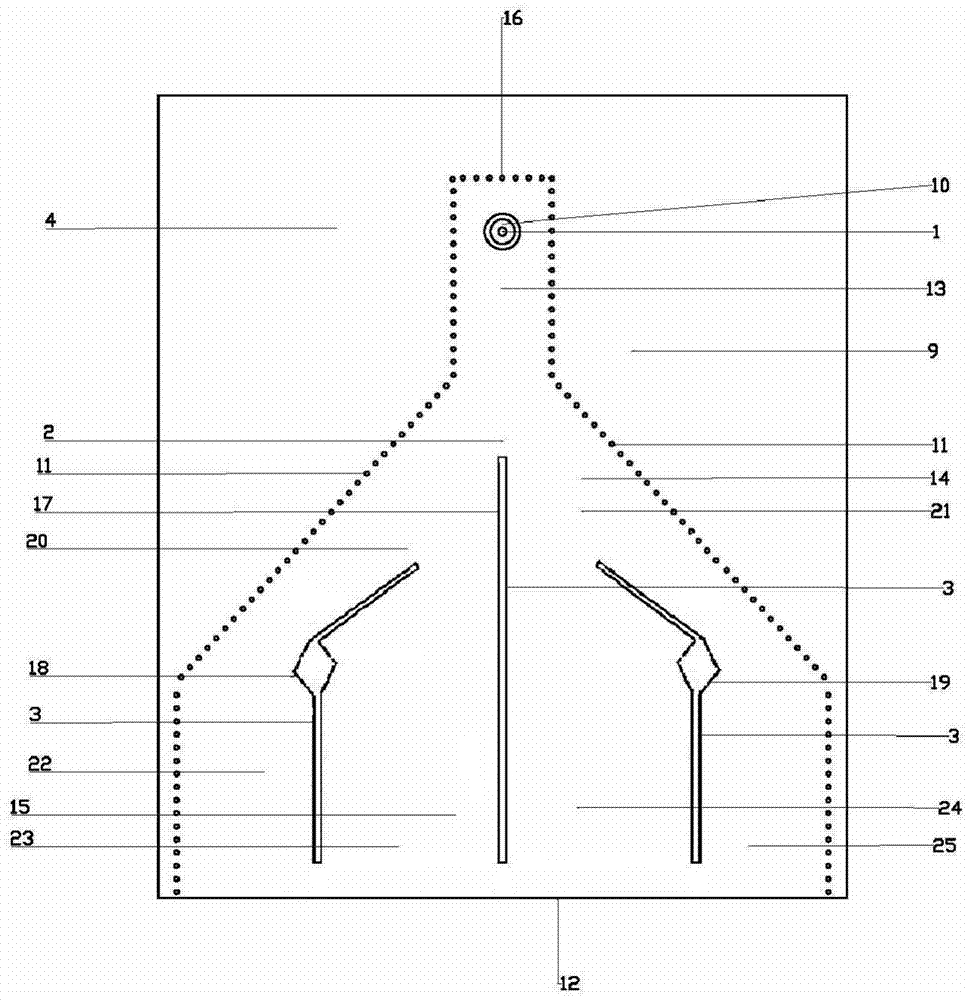

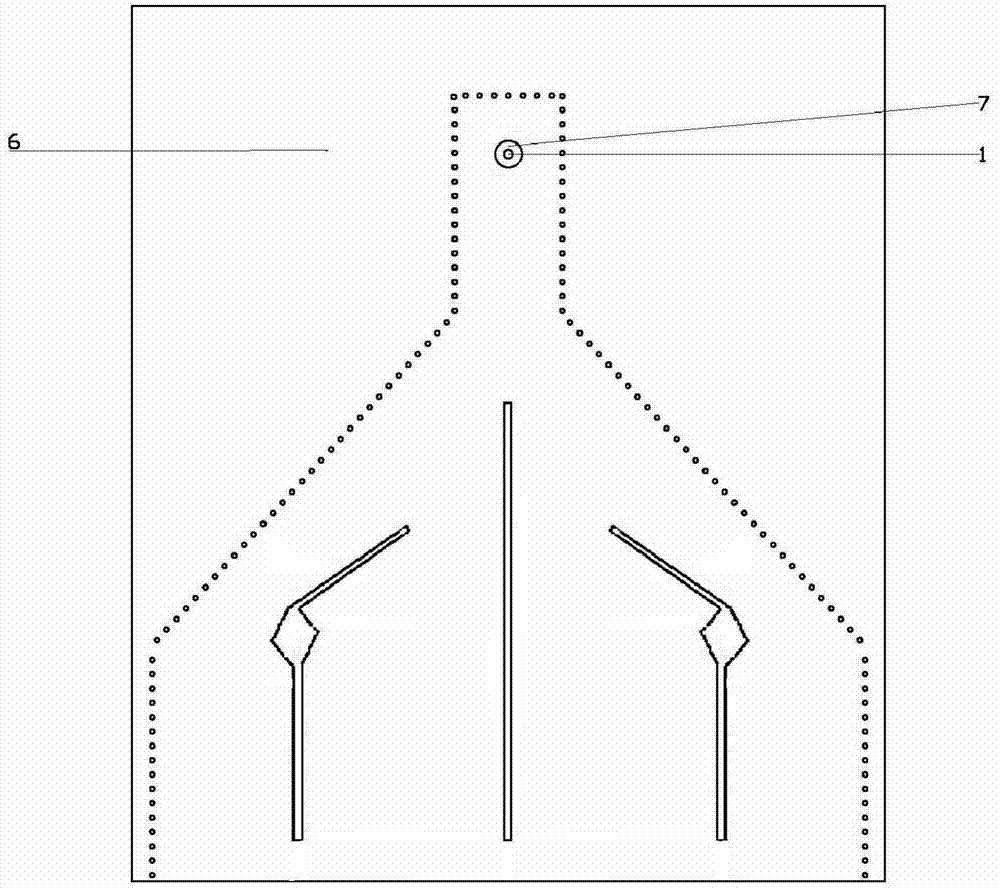

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] The embodiment adopted by the present invention is: the three-dimensional encapsulation surface antenna with embedded amplitude calibration in the gap includes a metallized vertical via hole feeder 1 arranged on a dielectric substrate 4, a substrate integrated waveguide horn antenna 2 and a gap 3, and the dielectric substrate 4 is placed on the dielectric substrate 4. The top of the three-dimensional package 5; the metallized vertical via hole feeder 1 is connected to the internal circuit 8 of the three-dimensional package 5; the substrate integrated waveguide horn antenna 2 is composed of a bottom metal plane 6 located on one side of the dielectric substrate 4 and located on the other side of the dielectric substrate 4. The top metal plane 9 on one side and the metallized via hole horn side wall 11 passing through the dielectric substrate 4 to connect the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com