Automatic egg collecting device

A transmission device and egg collection technology, which is applied in the application, poultry industry, poultry cages or houses, etc., to achieve the effect of improving the rigidity of operation, stable lifting, and satisfactory collection

Inactive Publication Date: 2015-06-24

SHANDONG UNIV OF TECH

View PDF6 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The automatic egg collection device only solves the problem of egg collection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

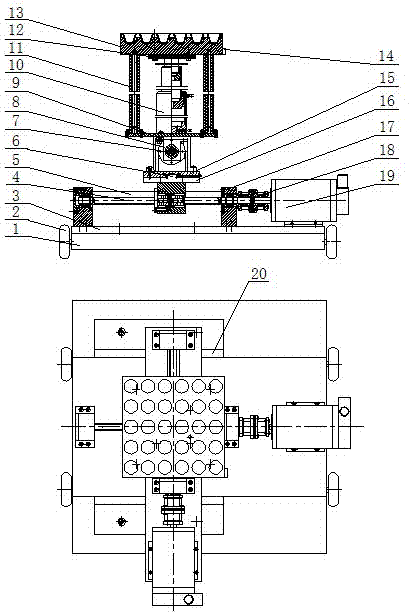

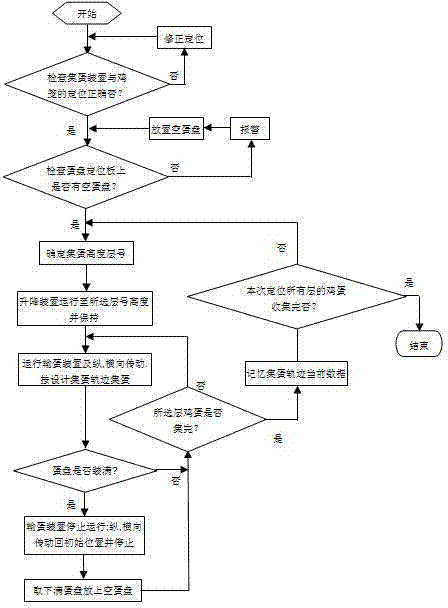

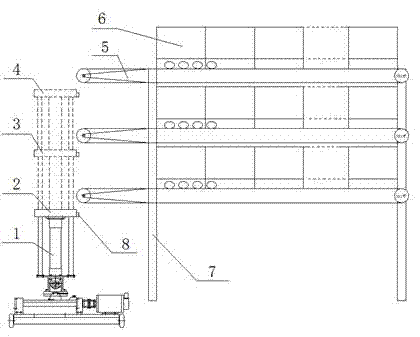

[0013] exist figure 1 , figure 2 , image 3 In the shown embodiment, at first the automatic egg collecting device and the chicken cage are pressed image 3 Positioning shown. Then turn on the control system, the control system follows the figure 2 The flow shown works to complete the automatic egg collection process.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a mechanical and electrical integrated automatic egg collecting device. The device is composed of a mechanical system and a control system. The automatic egg collecting process can be achieved according to the requirement of egg collecting work. The mechanical system is mainly composed of a base, idler wheels, a transverse transmission device, a longitudinal transmission device, an automatic lifting device, an egg tray positioning plate and the like. The control system is composed of a single chip microcomputer, an optoelectronic switch, an electromagnetic valve, a sensor, a control program, a control panel and the like. According to the automatic egg collecting device, the egg collecting height and track can be automatically controlled, eggs on hencoops at different heights are automatically collected, the labor intensity of feeders is lowered, the labor productivity is improved, the product quality is improved, and scale production of the breeding industry can be achieved. The automatic egg collecting device is suitable for egg production for a breeding enterprise and a farmer family livestock-raising industry with a certain scale.

Description

technical field [0001] The invention belongs to the technical field of electromechanical integration, and relates to the application principle, method and technical equipment of the electromechanical integration technology in poultry egg production. Background technique [0002] The aquaculture industry is the main export for human beings to obtain animal food and occupies an important position in the national economy. The mechanization and automation of aquaculture production can not only reduce the labor intensity of breeders, increase labor productivity, improve product quality, but also realize large-scale production of aquaculture. It is the only way to industrialize aquaculture and the basic guarantee for the modernization of aquaculture. [0003] Take raising chickens as an example. In the traditional aquaculture industry, there are four main operations in raising chickens, one is the supply of feed and water, the other is the collection of eggs, the third is the tre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01K31/16

CPCA01K31/165

Inventor 李彦蓉王相友孙传祝陈海真

Owner SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com