Hook automatic-return type longitudinal beam riveting production line

A production line and return-type technology, which is applied in the field of hook automatic return type stringer riveting production line, can solve the problems of low work efficiency and high labor intensity, and achieve the effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

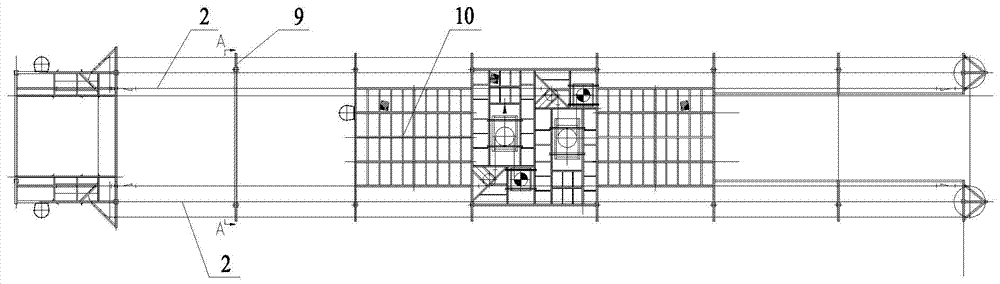

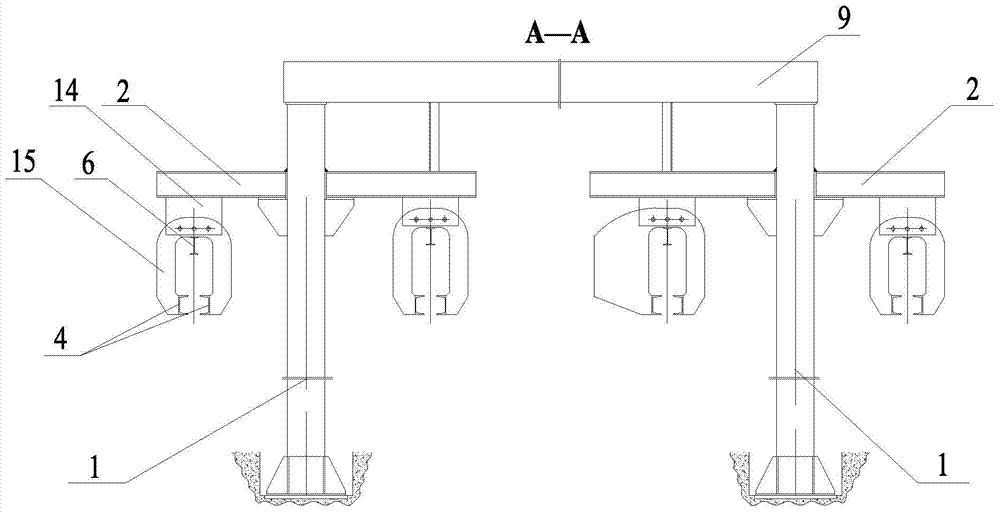

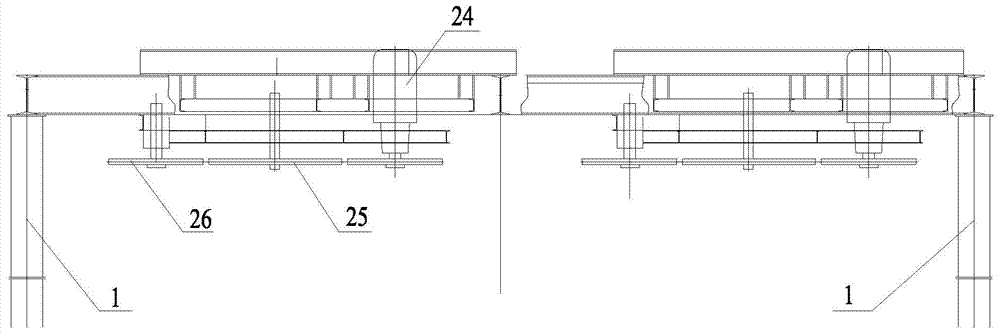

[0027] Such as figure 1 , Figure 4 , Figure 6 A hook automatic return longitudinal beam riveting production line shown in -8 includes a plurality of support columns 1 symmetrically arranged on the left and right sides of the production line and evenly spaced along the longitudinal direction. The upper part of the support columns 1 on the same side is fixed The steel structure longitudinal beam 2, the steel structure longitudinal beam 2 is fixed with the annular trolley track 4 of the transport frame longitudinal beam 3, the trolley track 4 is provided with a trolley 5, and the trolley 5 is provided with a spreader for hoisting the vehicle frame longitudinal beam 3 , the top of the trolley track 4 is provided with an annular traction chain track 6, and a plurality of conveying rollers 7 are arranged at intervals on the traction chain track 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com