Welding Tooling

A welding tooling and interface technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient welding of other parts, irregular openings of two pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

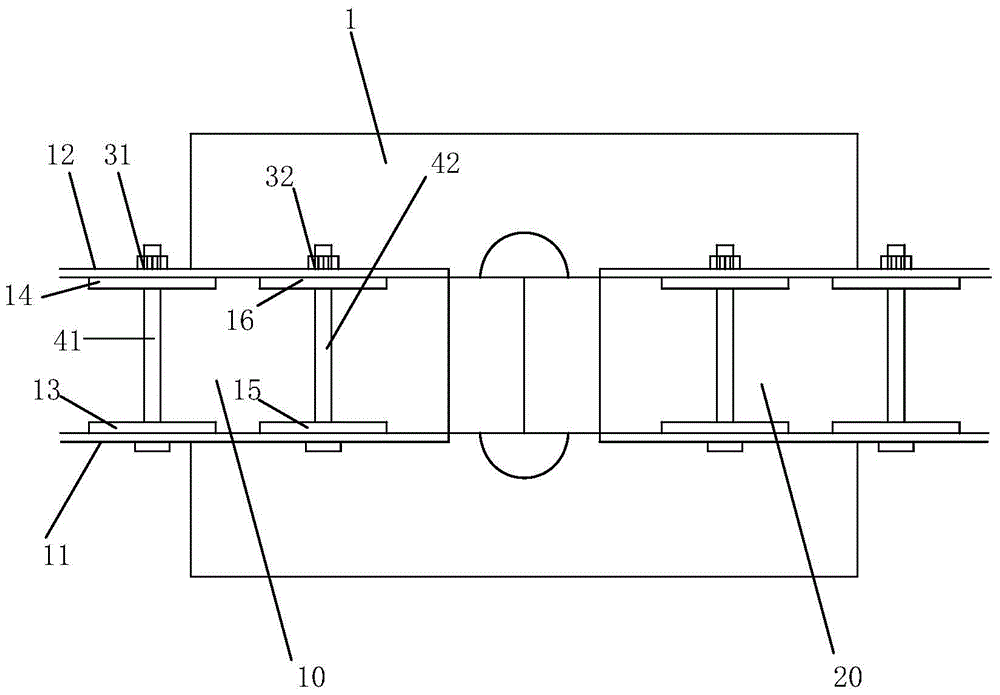

[0022] Please combine figure 1 It should be understood that a welding tool includes: an upper splint 1, a lower splint, and a pair of interface splints. The upper splint 1 and the lower splint are parallel to each other in the horizontal direction, so that the upper splint 1 and the lower splint can be restrained from being clamped. The movement of the objects in the vertical direction. There are two interface splints, which are parallel to each other in the vertical direction, and the two ends of the interface splint are respectively fixed to the upper splint 1 and the lower splint. Through the upper splint 1, the lower splint and a pair of interface splints, the welding tool actually preliminarily defines a rectangular space for clamping objects.

[0023] Please combine figure 1 It should be understood that in order to be able to realize the butt joint between the two pipeline interfaces, a welding hole should be opened on the interface splint, and the size of the welding hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com