An automatic production line for building industrialized concrete prefabricated components

An automatic production line and prefabricated component technology, which is applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of low automation and achieve the effects of improving labor efficiency, employing fewer people, and connecting compactly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

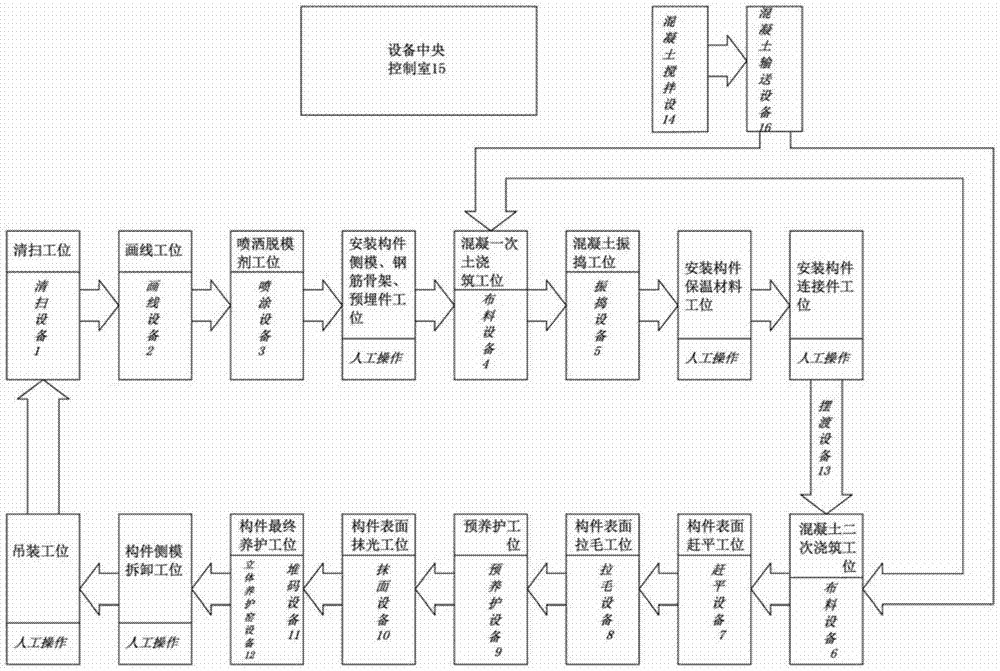

[0035] like figure 1 As shown, an automatic production line for building industrialized concrete prefabricated components. The production line takes each platform equipment as the basic unit, and the walking equipment and driving equipment are responsible for supporting the platform equipment to complete the transfer between the stations on the line. The stations include:

[0036] The surface cleaning station of the platform equipment is set up to complete the surface cleaning of the platform equipment;

[0037] The set platform equipment line drawing station is used to complete the outline of the component outline on the surface of the platform equipment;

[0038] The spraying release agent station on the surface of the platform equipment is set up to complete the spraying of the release agent on the surface of the platform equipment;

[0039] The installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com