Texture curing machine as well as method for the subsequent treatment of a freshly produced concrete layer

A technology of concrete layer, curing machine, applied in the direction of road, construction, road repair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

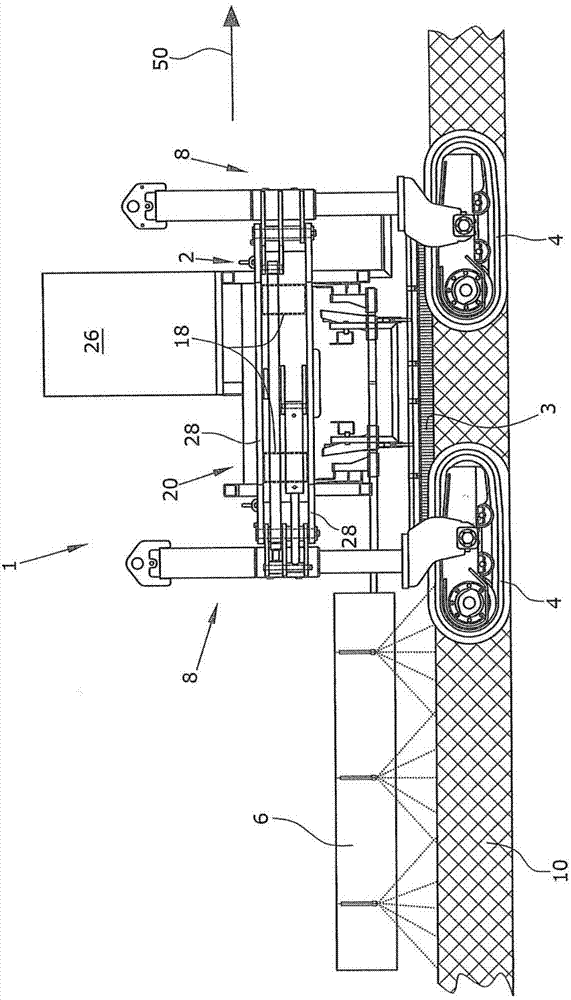

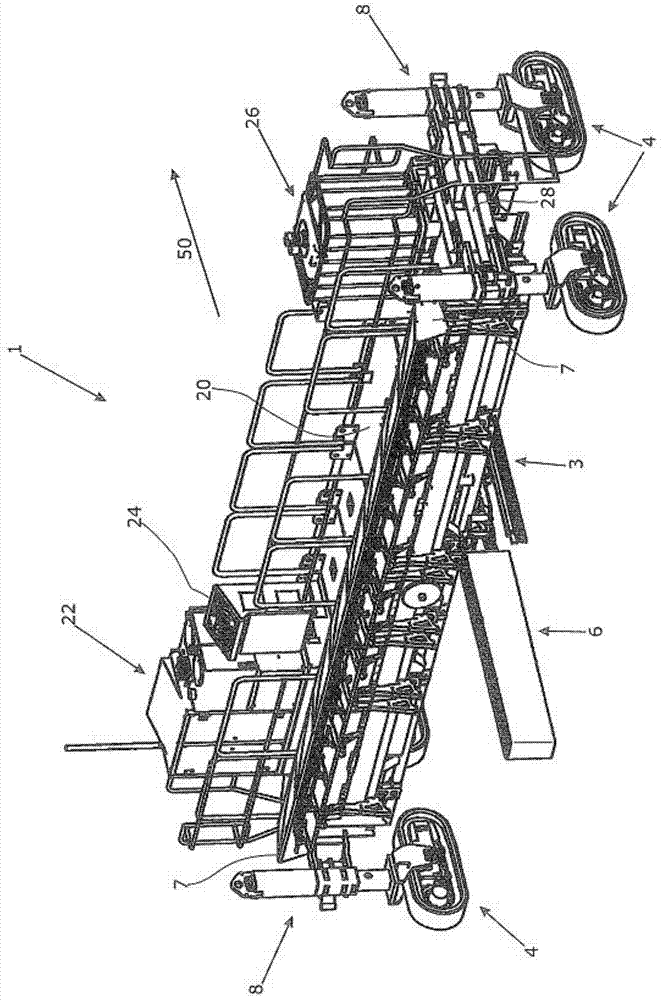

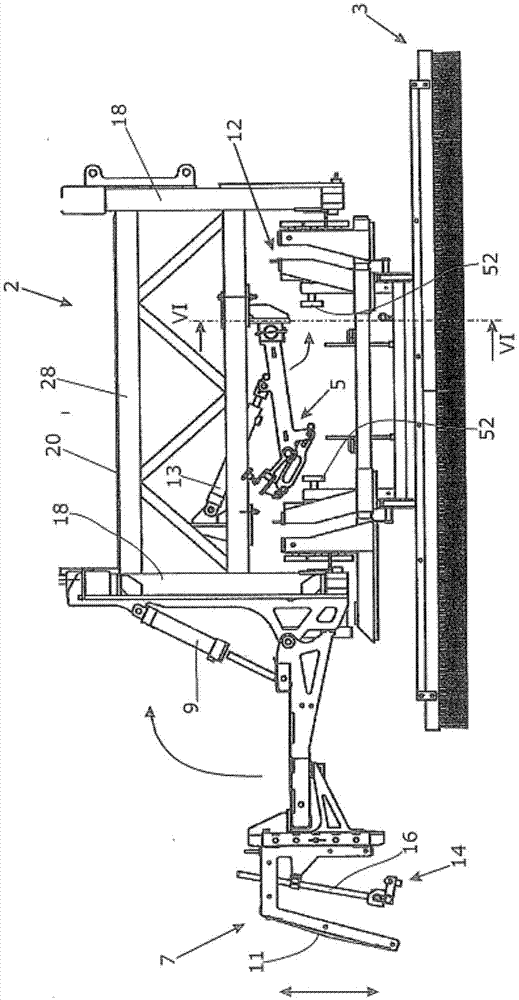

[0045] figure 1 A texture curing machine 1 as it is known from EP 1 841 637 A is shown in the embodiment of a brush sprayer. The texture curing machine 1 texturizes a newly created concrete layer 10 , such as a road surface, by means of a transverse texturing device 3 such as a brush assembly, and then sprays said concrete layer with a liquid curing agent by means of a spraying assembly 6 .

[0046] The machine frame 2 is provided with a height suitable for transport on a transport vehicle, so that the machine can be transported to the operating site by being loaded on the transport vehicle. The machine frame is provided with a width that is a multiple of its height, for example with available widening elements or telescopic machine frame 2 for adjustment to a specific paving width. In this arrangement, for example paved road widths up to 18 m can be figure 1 The job location shown in bridging. The working direction is indicated by arrow 50 in the various figures.

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com