Factory-produced high-efficiency prefabricated building floor slab and manufacturing method

A prefabricated and factory-like technology, applied in the direction of architecture and building structure, can solve problems affecting quality, unreasonable concrete design, construction and maintenance measures, cracking of floors, etc., and achieve fast construction and installation, convenient installation and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

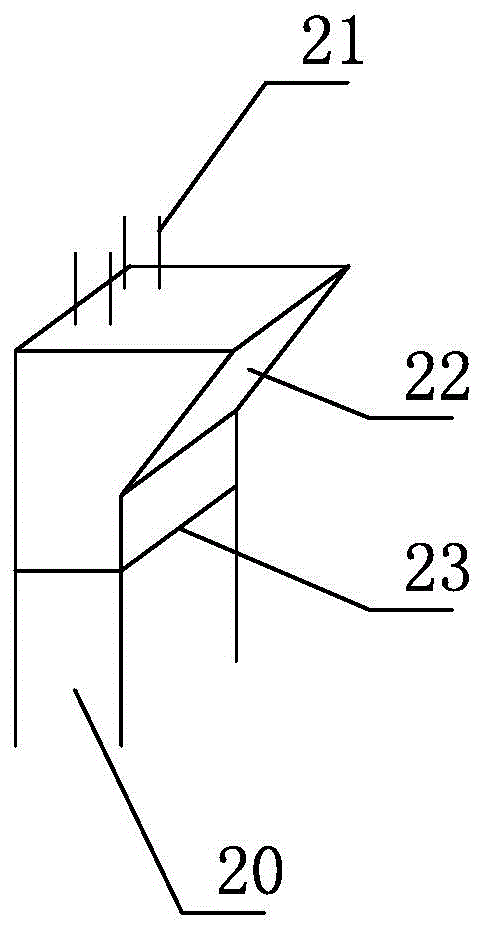

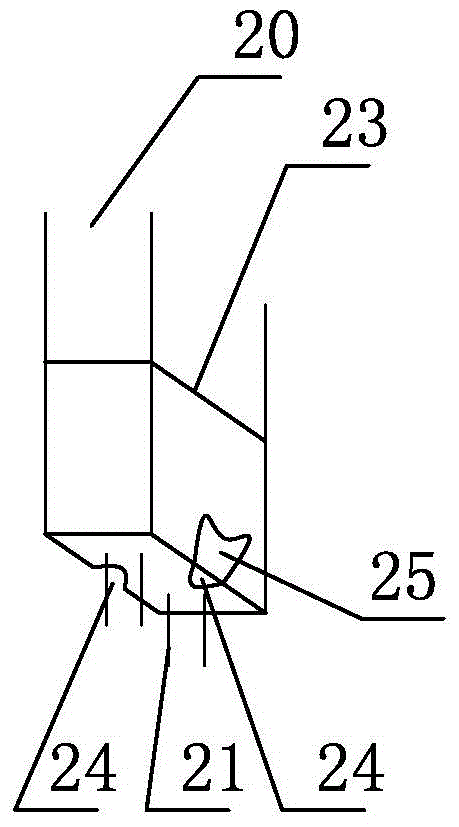

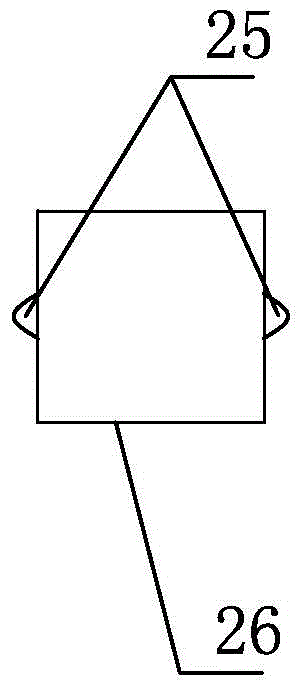

[0042] Embodiment 1: Industrial production of high-efficiency prefabricated building floor slabs and production methods, as attached figure 1 - attached Figure 24 As shown, it includes a floor body 1 that can be connected with columns 20 and beams 30. It is characterized in that: the longitudinal cross section of the floor body 1 is trapezoidal; The steel head 4 is formed on the wall and protrudes from the side wall; welding holes are arranged on the trapezoidal end surface of the floor body 1, and the steel bar head 4 located on the trapezoidal end surface is exposed from the welding hole.

[0043] The floor body 1 is a hollow structure with several holes 5 .

[0044] The reinforcement frame is a double-layer structure, including an upper layer 2 and a lower layer 3; on the trapezoidal end face of the floor body 1, a steel bar 6 is arranged between the corresponding steel bar heads 4 in the upper layer 2 and the lower layer 3 to connect.

[0045] Between the slabs, the con...

Embodiment 2

[0053] Embodiment 2: The manufacturing method of the present invention's factory-produced high-efficiency prefabricated building floor slab and its manufacturing method. After the floor slab is placed on the beam, the exposed steel bars at both ends of the floor slab and the embedded iron or reserved steel bars on the beam are welded and fixed; the floor slab and The horizontal connection of the floor and the horizontal connection between the floor and the beam are connected and fixed by welding the exposed steel bars; the outermost horizontal exposed steel bar head of the floor is welded and fixed with the embedded iron or reserved steel bar on the beam.

[0054] The connection gaps between floor slabs and floor slabs and beams shall be filled with concrete materials.

[0055] The present invention is a novel high-strength prefabricated prefabricated floor slab (hereinafter referred to as "this product" or "floor") produced in a factory, and can be matched with a new type of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com