Two-step sublevel open-stop and delayed filling mining method

A filling mining and empty field technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of low safety and reliability, high filling cost, high cemented filling strength, etc., to achieve strong safety and reliability, and simplify the bottom structure , The effect of reducing the loss of the bottom pillar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

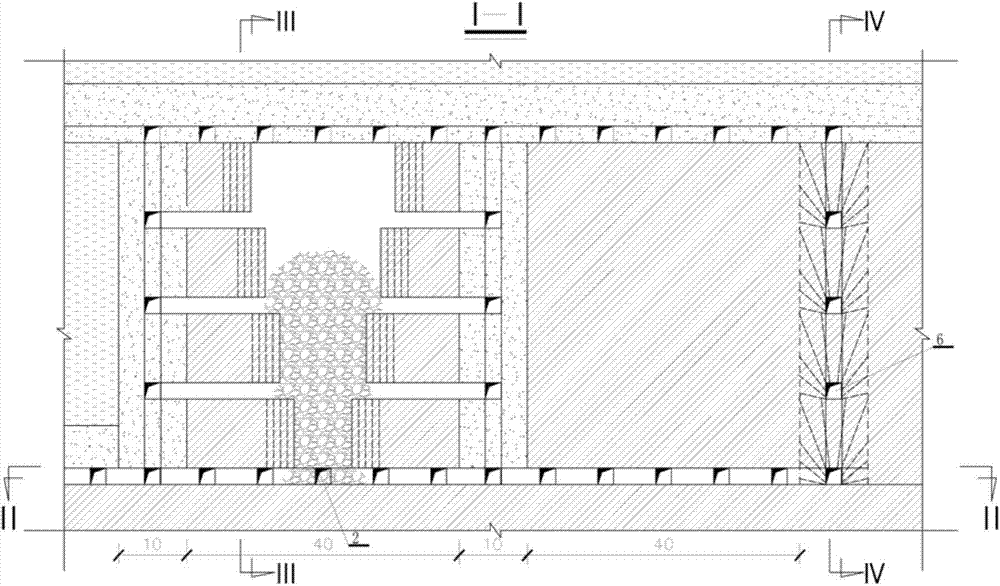

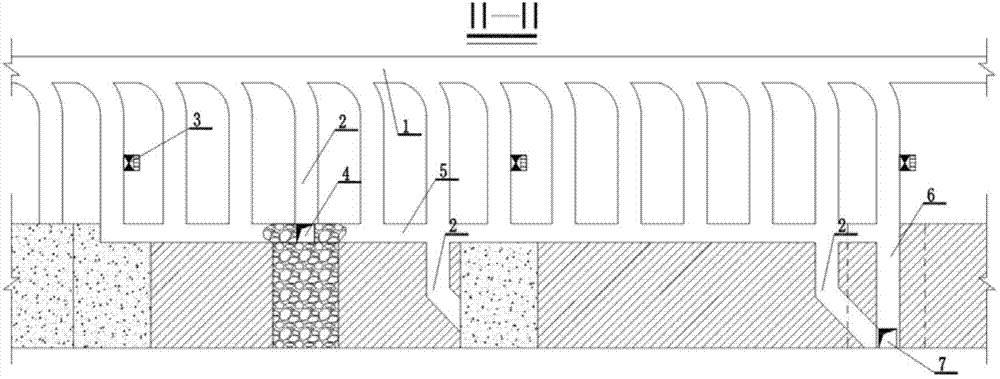

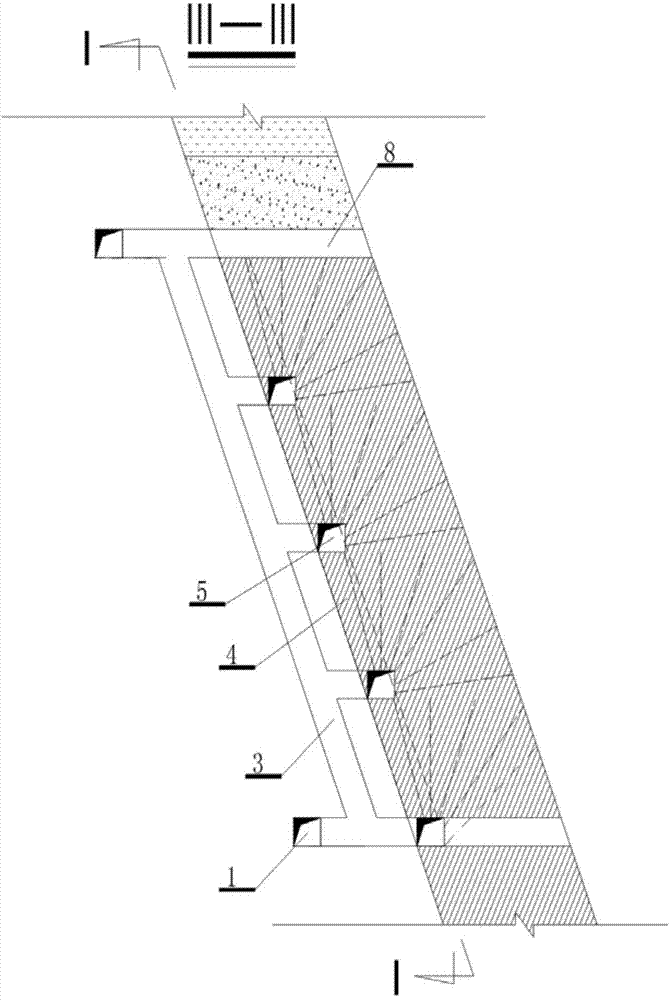

[0039] In a certain antimony mine in the Tibet Autonomous Region of my country, the average dip angle of the ore body is 53°, and the average thickness is 13m. ) volcanic tuff, limestone, the surrounding rock is relatively hard, but joints and fissures are relatively developed in some sections, and the stability is medium. Use the mining method described in the present invention to mine this ore body, combine figure 1 , figure 2 , image 3 , Figure 4 The specific implementation is described as follows:

[0040] 1. Block layout and components

[0041] The ore blocks are arranged along the strike, with a length of 50m, a width of the horizontal thickness of the ore body, and a height of 50m in the middle section. No top pillar, no bottom pillar, 10m inter-pillar, 40m mine house, 12.5m section height.

[0042] 2. Procurement and cutting

[0043] Inter-column mining and cutting: use the layout outside the vein, from the development of the transport roadway 1 arranged o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com