Swelling agent special for traffic engineering and production method of swelling agent

A technology of traffic engineering and expansion agent, which is applied in the field of special expansion agent for traffic engineering, which can solve the problems of slurry settlement and cracking, and achieve the effects of reducing sinking, high viscosity, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

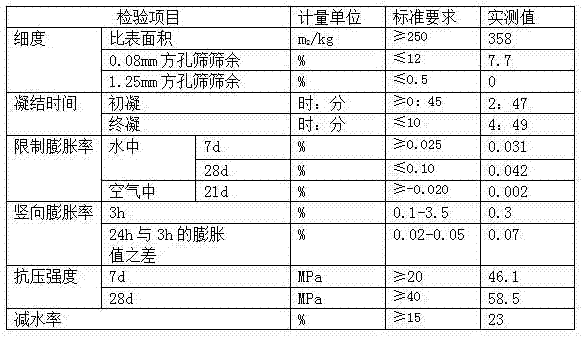

Embodiment 1

[0044] A special expansion agent for traffic engineering, the special expansion agent for traffic engineering comprises the following raw materials in parts by weight:

[0045] Expansion masterbatch: 100;

[0046] Active mineral admixture: 6;

[0047] Plastic expansion agent: 3;

[0048] Preservatives: 1;

[0049] Lignin-based water reducer: 2;

[0050] The expansion masterbatch contains the following raw materials in parts by weight:

[0052]Iron-aluminate clinker: 50;

[0053] Construction waste: 52.

[0054] The gypsum slag is the slag after beneficiation of mirabilite ore, and its chemical composition: LOSS13.28%, SiO 2 33.43%, Fe 2 o 3 3.23%, Al 2 o 3 9.63%, CaO12.75, MgO7.34, SO 3 20.09%.

[0055] The ferro-aluminate clinker is made of calcium carbonate, low-grade bauxite, hematite and gypsum in a weight ratio of 3:5:2:1, after being calcined at 1300~1350°C, and then added with a weight percentage of 5 - Clinker made by co-grinding...

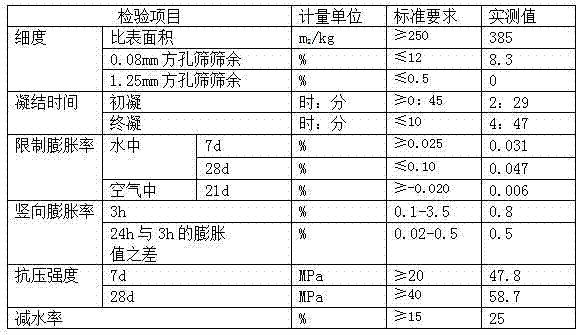

Embodiment 2

[0072] A special expansion agent for traffic engineering, the special expansion agent for traffic engineering comprises the following raw materials in parts by weight:

[0073] Expansion masterbatch: 110;

[0074] Active mineral admixture: 7;

[0075] Plastic expansion agent: 4;

[0076] Preservatives: 2;

[0077] Lignin-based water reducer: 5;

[0078] The expansion masterbatch contains the following raw materials in parts by weight:

[0079] Gypsum slag: 70;

[0080] Ferric aluminate clinker: 55;

[0081] Construction waste: 55.

[0082] The gypsum slag is the slag after beneficiation of mirabilite ore, and its chemical composition: LOSS13.28%, SiO 2 33.43%, Fe 2 o 3 3.23%, Al 2 o 3 9.63%, CaO12.75, MgO7.34, SO 3 20.09%.

[0083] The ferro-aluminate clinker is made of calcium carbonate, low-grade bauxite, hematite and gypsum in a weight ratio of 3:5:2:1, after being calcined at 1300~1350°C, and then added with a weight percentage of 5 - Clinker made by co-grind...

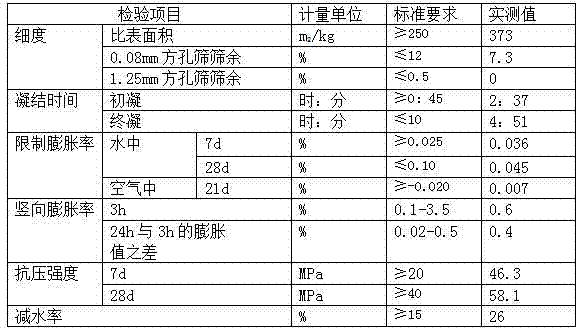

Embodiment 3

[0100] A special expansion agent for traffic engineering, the special expansion agent for traffic engineering comprises the following raw materials in parts by weight:

[0101] Expansion masterbatch: 120;

[0102] Active mineral admixture: 8;

[0103] Plastic swelling agent: 5;

[0104] Preservatives: 3;

[0105] Lignin-based water reducer: 8;

[0106] The expansion masterbatch contains the following raw materials in parts by weight:

[0107] Gypsum slag: 75;

[0108] Ferric aluminate clinker: 60;

[0109] Construction waste: 58.

[0110] The gypsum slag is the slag after beneficiation of mirabilite ore, and its chemical composition: LOSS13.28%, SiO 2 33.43%, Fe 2 o 3 3.23%, Al 2 o 3 9.63%, CaO12.75, MgO7.34, SO 3 20.09%.

[0111] The ferro-aluminate clinker is made of calcium carbonate, low-grade bauxite, hematite and gypsum in a weight ratio of 3:5:2:1, after being calcined at 1300~1350°C, and then added with a weight percentage of 5 - Clinker made by co-grindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com