Steel shell immersed tube self-compacting concrete mix proportion design method and concrete

A technology of self-compacting concrete and mix ratio design, applied in the field of building materials, can solve problems such as non-compacting, difficult to detect, and large performance fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the following, the present invention will be further described in conjunction with specific implementation methods. It should be noted that, on the premise of not conflicting, the various embodiments or technical features described below can be combined arbitrarily to form new embodiments. The materials used in this embodiment can be purchased from the market.

[0053] The principle of the present invention's design is:

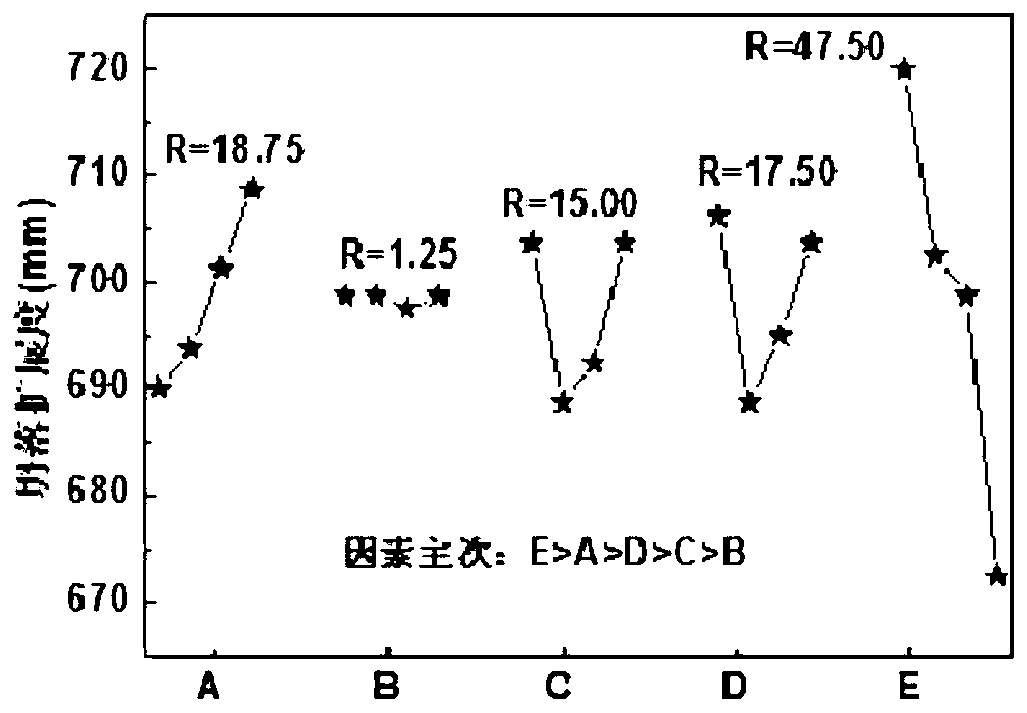

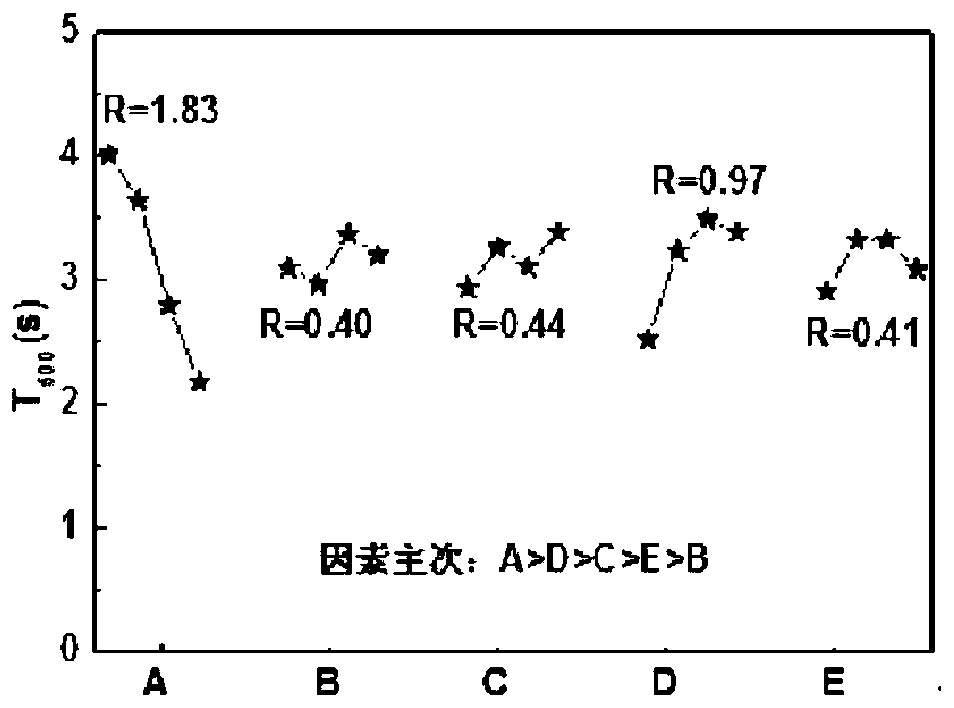

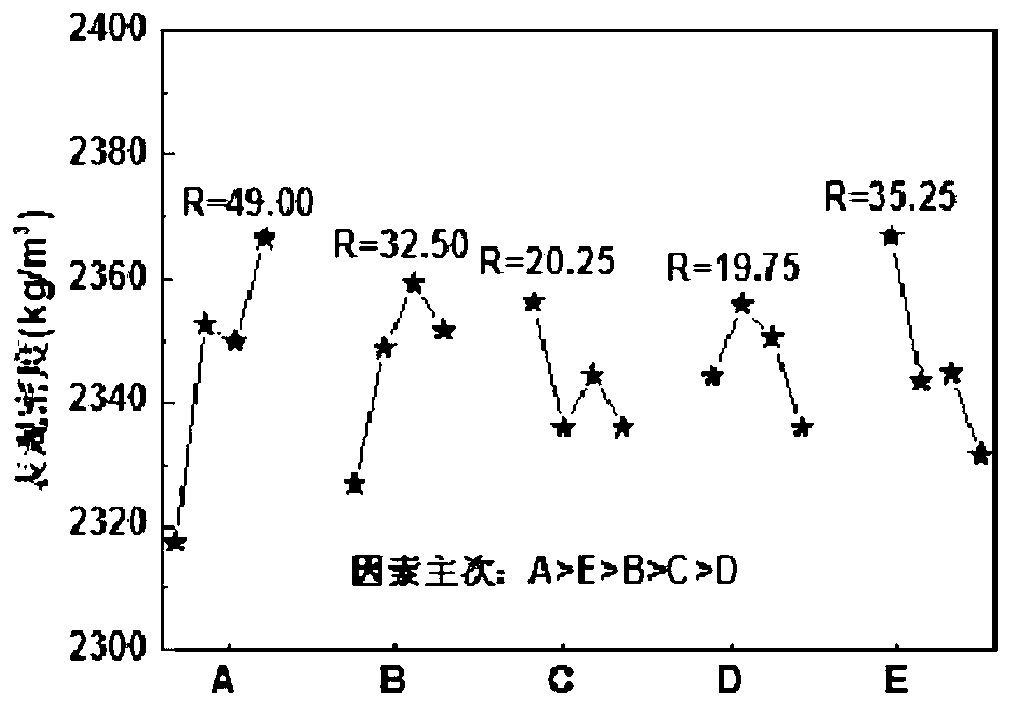

[0054] The guarantee of the working performance of steel shell immersed tube concrete is very critical to the quality assurance of steel shell immersed tube. The calculation method of fixed sand and gravel volume content fully considers the working performance of self-compacting concrete, that is, the high flow of steel shell immersed tube self-compacting concrete Filling performance, as well as the ability to resist segregation and bleeding, to adjust the amount of raw materials for each component of steel shell immersed tube self-compacting concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| slump spread | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com