A Stiffness Adjustable Variable Damping Back Vibration Isolator

A variable damping and adjustable technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as unfavorable energy absorption, easy deformation of wire mesh pads, and affecting the horizontal stiffness of the back vibration isolator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

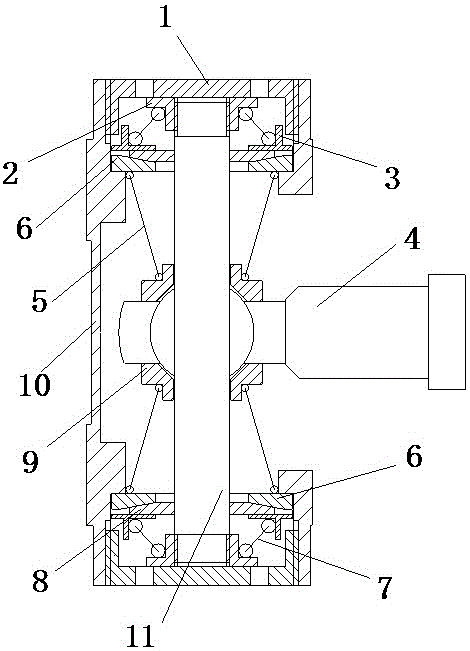

[0039] Such as figure 1 As shown, an adjustable stiffness variable damping back vibration isolator includes a housing 10 and a central shaft 11, the central shaft 11 is vertically arranged in the housing 10, and the upper and lower ends of the housing 10 respectively form a horizontal damping chamber, The upper and lower ends of the central shaft 11 are respectively located in two horizontal damping cavities, and the two horizontal damping cavities are respectively provided with adjustment devices for adjusting the stiffness and damping of the central shaft 11 when moving horizontally.

[0040] The adjustment device includes a damper, an inner cone spring 7 and an inner adjusting screw sleeve 2, and the inner adjusting screw sleeve 2 is helically connected to the end of the central shaft 11. The damper includes a damping retaining ring 6 and a damping cone ring 8, and the damping retaining ring 6 and The damping cone ring 8 is made of metal material, and the damping retaining ...

Embodiment 2

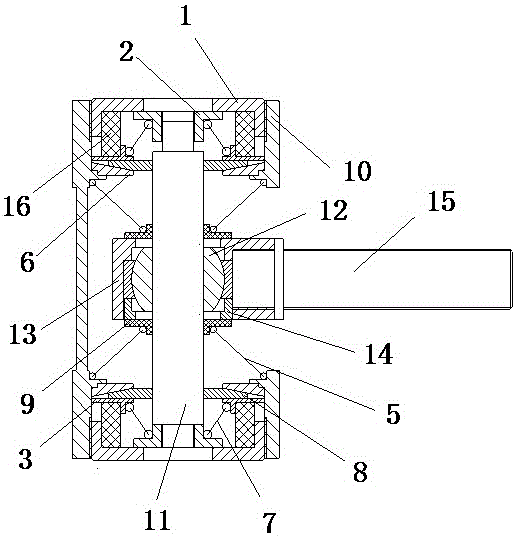

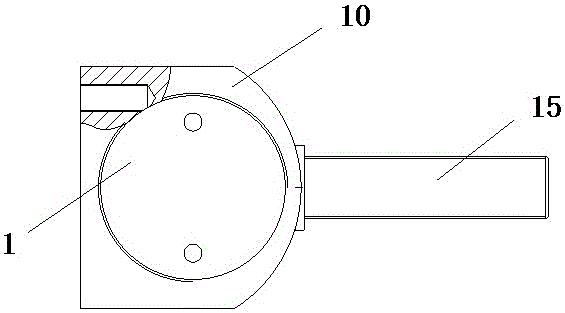

[0047] Such as figure 2 and image 3 As shown, an adjustable stiffness variable damping back vibration isolator includes a housing 10 and a central shaft 11, the central shaft 11 is vertically arranged in the housing 10, and the upper and lower ends of the housing 10 respectively form a horizontal damping chamber, The upper and lower ends of the central shaft 11 are respectively located in two horizontal damping cavities, and the two horizontal damping cavities are respectively provided with adjustment devices for adjusting the stiffness of the central shaft 11 when moving horizontally.

[0048] The adjustment device includes a damper, an inner cone spring 7 and an inner adjusting screw sleeve 2, and the inner adjusting screw sleeve 2 is helically connected to the end of the central shaft 11. The damper includes a damping retaining ring 6 and a damping cone ring 8, and the damping retaining ring 6 and The damping cone ring 8 is made of metal material, and the damping retaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com