Solid-phase extraction device used for pre-treating sample

A technology of sample pretreatment and solid-phase extraction column, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of restricting sample pretreatment time, inability to replace the receiving tube conveniently, and affecting the application range, etc., so as to facilitate popularization and application , easy to clean, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of application of the present invention.

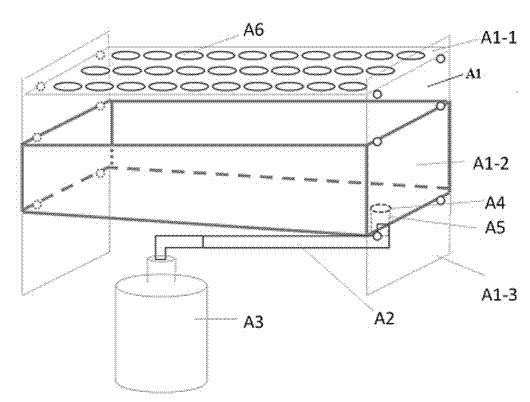

[0034] like figure 1 As shown, the solid phase extraction separation device (A) of the present invention is composed of a main frame (A1), a connecting pipe (A2) and a waste liquid collection bottle (A3), and the main frame (A1) is composed of a porous plate (A1-1) , a solution buffer pool (A1-2), and support frames on both sides (A1-3), wherein the solution buffer pool (A1-2) consists of a slightly inclined bottom surface and surrounding panels. There is a round hole (A4) on the lower side of the bottom of the solution buffer pool (A1-2), and a drainer (A5) with a round top and a pointed bottom below it, and the porous plate (A1-1) has a round hole (A6).

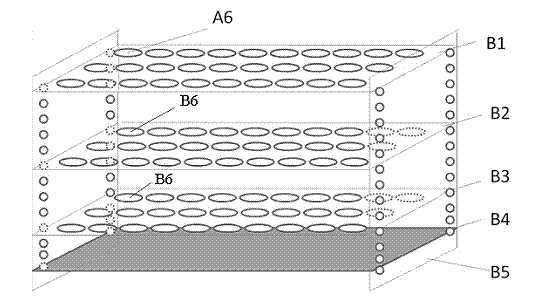

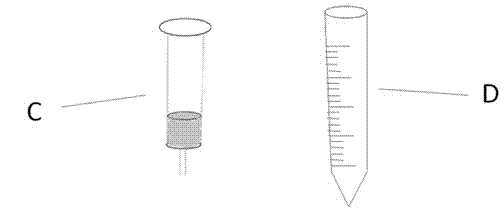

[0035] like figure 2 As shown, the solid phase e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com