Terminal pulling-out force detecting method

A detection method and pull-off force technology, which are applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of increasing detection costs and heavy workload, and achieve the effects of reducing inspection costs and frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

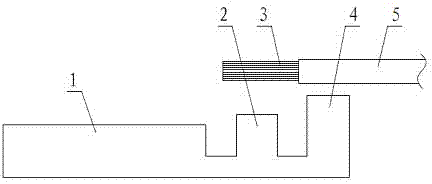

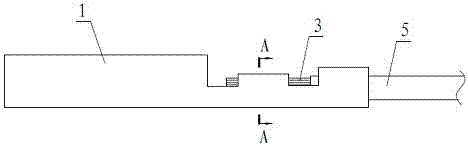

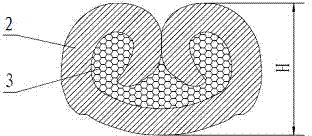

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0042] In order to illustrate the rationality of this method, the source of variation affecting the pull-off force is firstly identified through C&E and DOE methods. For general sources of variation, through the control of suppliers, raw materials, equipment, etc., they are controlled under specified conditions, so as to eliminate the impact on pull-off force. For the main source of variation, it is necessary to conduct in-depth research through methods such as SPC and regression analysis to find the relationship between pull-off force and crimping height, and establish a mathematical model to determine the optimal crimping height.

[0043] Now take FDHF-8E terminal crimping 20mm2 wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com