Electromagnetic valve fault detection circuit and detection method

A fault detection circuit and solenoid valve technology, applied in circuit breaker testing, current/voltage measurement, measurement devices, etc., can solve problems such as reduced production efficiency, lack of solenoid valve fault detection and alarm links, economic losses, etc. Qualified products, reduce inspection personnel and inspection frequency, and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Embodiment Solenoid valve fault detection circuit and detection method

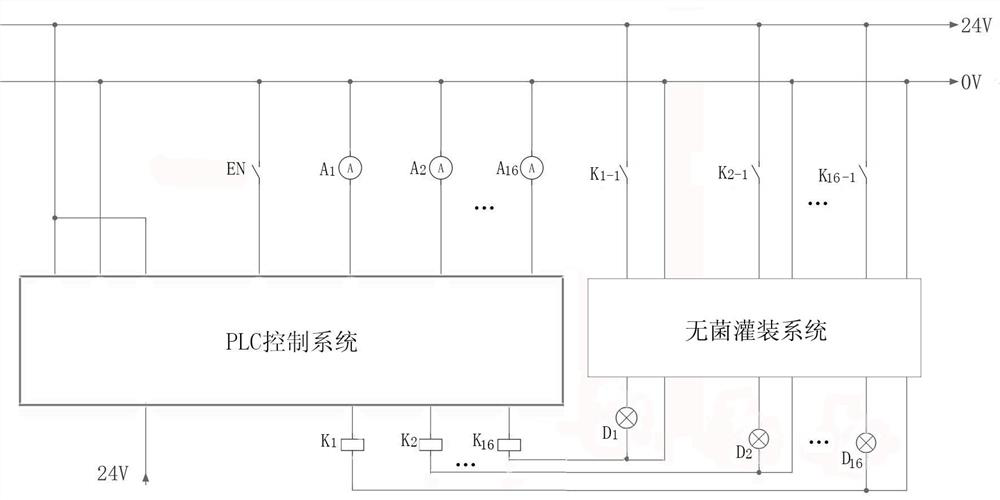

[0019] A solenoid valve fault detection circuit, such as figure 1 As shown, based on the existing Wipak aseptic filling machine settings, the equipment is equipped with 32 solenoid valves, two parallel solenoid valves as a group, a total of 16 solenoid valve groups, of which 15 solenoid valve groups are set On the rotary table, a solenoid valve group is set on a fixed station. The solenoid valve fault detection circuit is based on the control of the PLC control system. The PLC control system stores a detection program for the number of rotations of the rotary table. Each solenoid valve group are connected in series with an ammeter (i.e. A 1 -A 16 ), the relay alarm and electric shock output signal of each ammeter is sent to the PLC control system, and the alarm signal output terminal of the PLC control system is connected to the alarm device. The alarm device includes an alarm cabinet placed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com