A kind of multifunctional composite non-woven fabric and its preparation system

A preparation system and non-woven fabric technology, applied in melt spinning, non-woven fabrics, textiles and papermaking, etc., can solve the problems of low production efficiency and poor quality of non-woven fabrics, and improve production coordination And production efficiency, improve the uniformity of thickness distribution, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, a spinning system is configured to carry out mixing and quantitative processing on the raw materials and further spray them to the collecting net and form the spinning net with a uniform thickness;

[0030]A multi-functional composite non-woven fabric and its preparation system, the preparation system includes a raw material processing module for precise feeding and hot-melt spraying of the composite non-woven raw material, processing the raw material processed by the raw material processing module The fiber spinning that is further extruded through the spinneret is subjected to adsorption and collection of corresponding intensity to further form a collection module of a uniformly structured spinneret net, a winding module that quantitatively winds and collects the spinneret net, and the collection module The temperature distribution of the spinning net on the screen is monitored, and the temperature adjustment module is further carried out on the spi...

Embodiment 2

[0038] This embodiment constructs a production system that effectively improves the thickness distribution of the spinneret and further improves the quality of the composite nonwoven fabric;

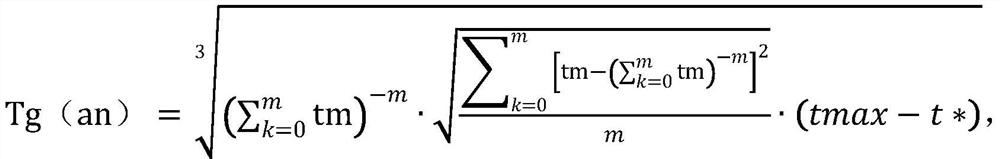

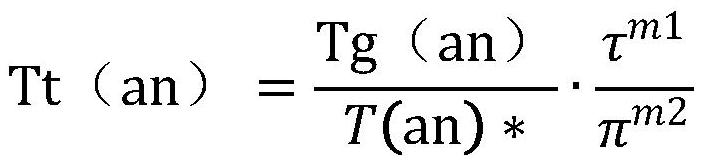

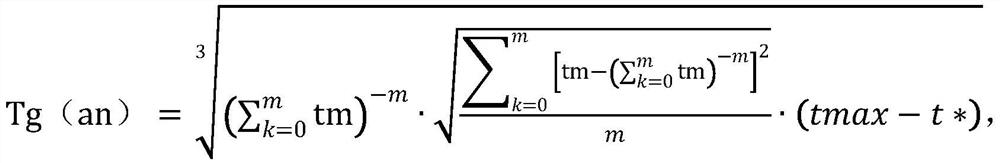

[0039]A multi-functional composite non-woven fabric and its preparation system, the preparation system includes a raw material processing module for precise feeding and hot-melt spraying of the composite non-woven raw material, processing the raw material processed by the raw material processing module The fiber spinning that is further extruded through the spinneret is subjected to adsorption and collection of corresponding intensity to further form a collection module of a uniformly structured spinneret net, a winding module that quantitatively winds and collects the spinneret net, and the collection module The temperature distribution of the spinning net on the screen is monitored, and the temperature adjustment module is further carried out on the spinning net for corresponding matchi...

Embodiment 3

[0059] This embodiment constructs a winding collection module that automatically quantitatively carries out winding collection to the finished spinneret to further improve the efficiency of the non-woven fabric production line;

[0060] A multi-functional composite non-woven fabric and its preparation system, the preparation system includes a raw material processing module for precise feeding and hot-melt spraying of the composite non-woven raw material, processing the raw material processed by the raw material processing module The fiber spinning that is further extruded through the spinneret is subjected to adsorption and collection of corresponding intensity to further form a collection module of a uniformly structured spinneret net, a winding module that quantitatively winds and collects the spinneret net, and the collection module The temperature distribution of the spinning net on the screen is monitored, and the temperature adjustment module is further carried out on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com