A device for detecting shelf beams by using ring optical fiber group

A shelf beam and optical fiber detection technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inability to detect shelf beams, unqualified products in batches, and high cost of industrial cameras, so as to avoid the probability of unqualified products, The effect of low production cost and convenient detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

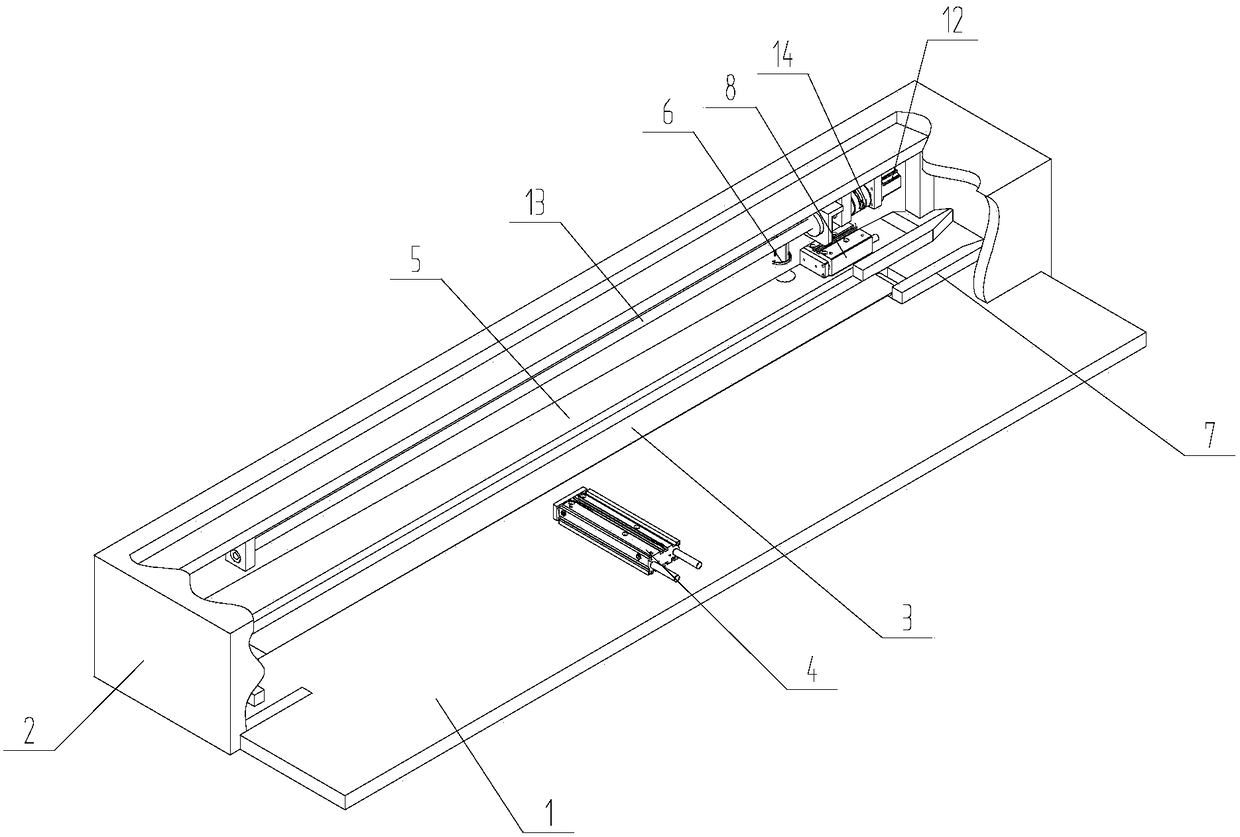

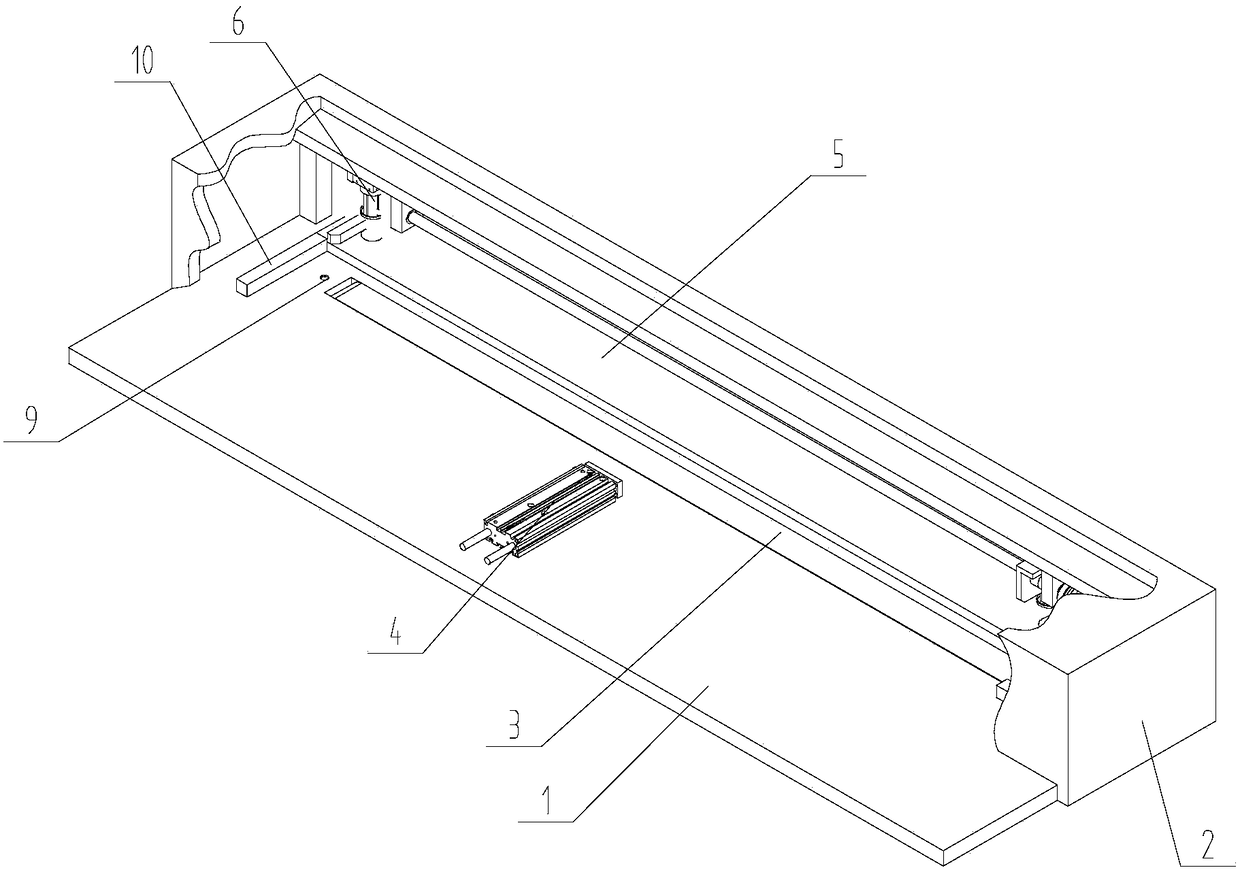

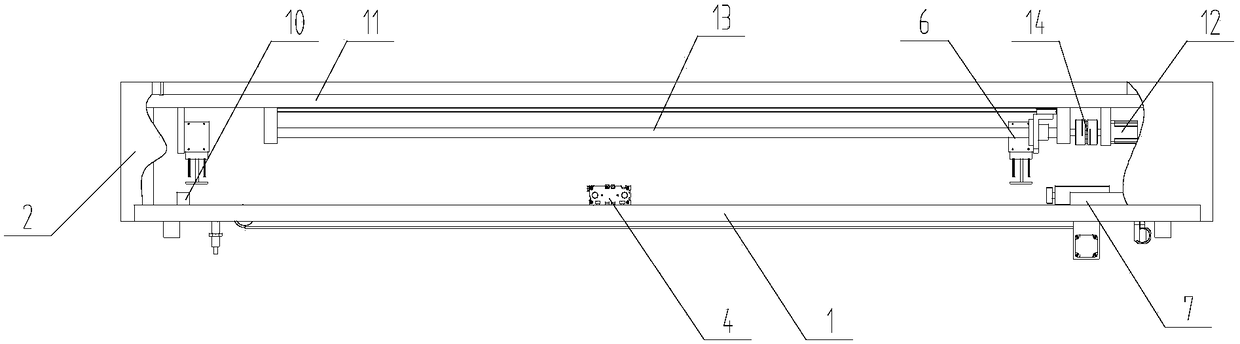

[0035] Below in conjunction with accompanying drawing, the present invention is further described:

[0036] refer to Figure 1-8 As shown, a device for detecting shelf crossbeams using annular optical fiber groups in the present invention includes a base 1, a conveyor belt 3, a proximity switch 9, a stopper 10, a push cylinder 4, a measuring bracket 5, an optical fiber detection module, a parallel light source, Closed housing 2 and pressing cylinder 8, the closed housing 2 is fixed above the base 1, the conveyor belt 3, proximity switch 9, block 10, measuring bracket 5, optical fiber detection module, parallel light source and pressing The cylinders 8 are all arranged inside the closed casing 2; the conveyor belt 3 is arranged on the base 1, and the proximity switch 9 and the stopper 10 are sequentially arranged on the base 1 along the direction of the outlet of the conveyor belt 3, and the proximity switch 9 is embedded On the base 1, the stopper 10 is fixed above the base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com