Automatic water supplement device for coal gas purification system and control method of device

A purification system and automatic water replenishment technology, applied in water supply devices, water supply devices, water supply pipeline systems, etc., can solve problems such as environmental accidents, easy flooding, waste of human resources, etc., to save water costs, prevent flooding, and avoid environmental protection The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

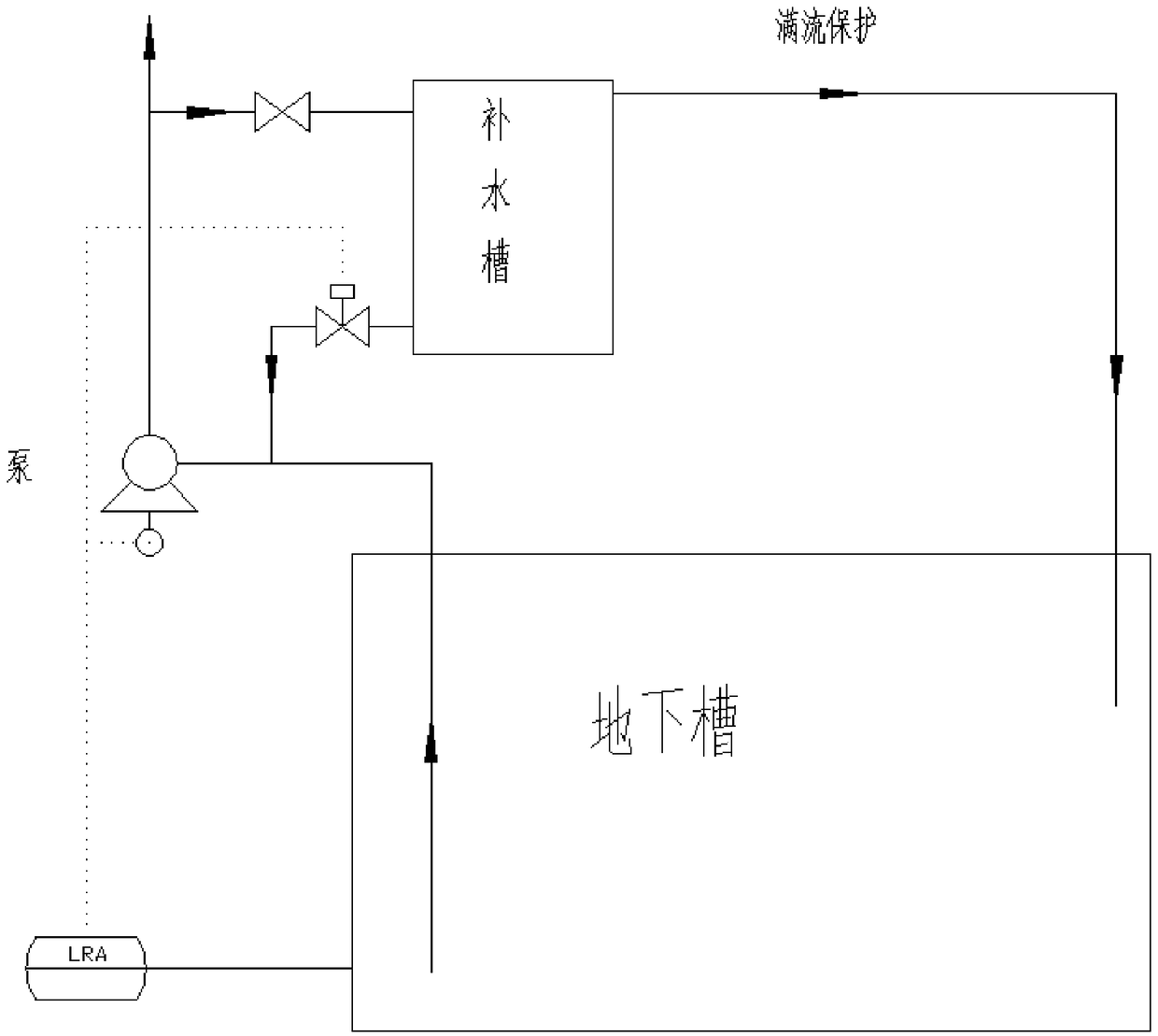

[0025] Such as figure 1 As shown, a new water replenishment tank can be added. The water replenishment tank can be a vertical tank of one cubic meter. The water outlet height is greater than the irrigation pump port. The water outlet of the water replenishment tank is connected to the irrigation pump port of the pump through a pipeline, and one end of the suction pipe extends into the ground. In the tank, the other end is connected to the water inlet of the pump, and the water outlet of the pump is connected to the water outlet pipe. The pipeline connecting the pump and the water supply tank is provided with a first valve, and the start of the pump is controlled by a delay.

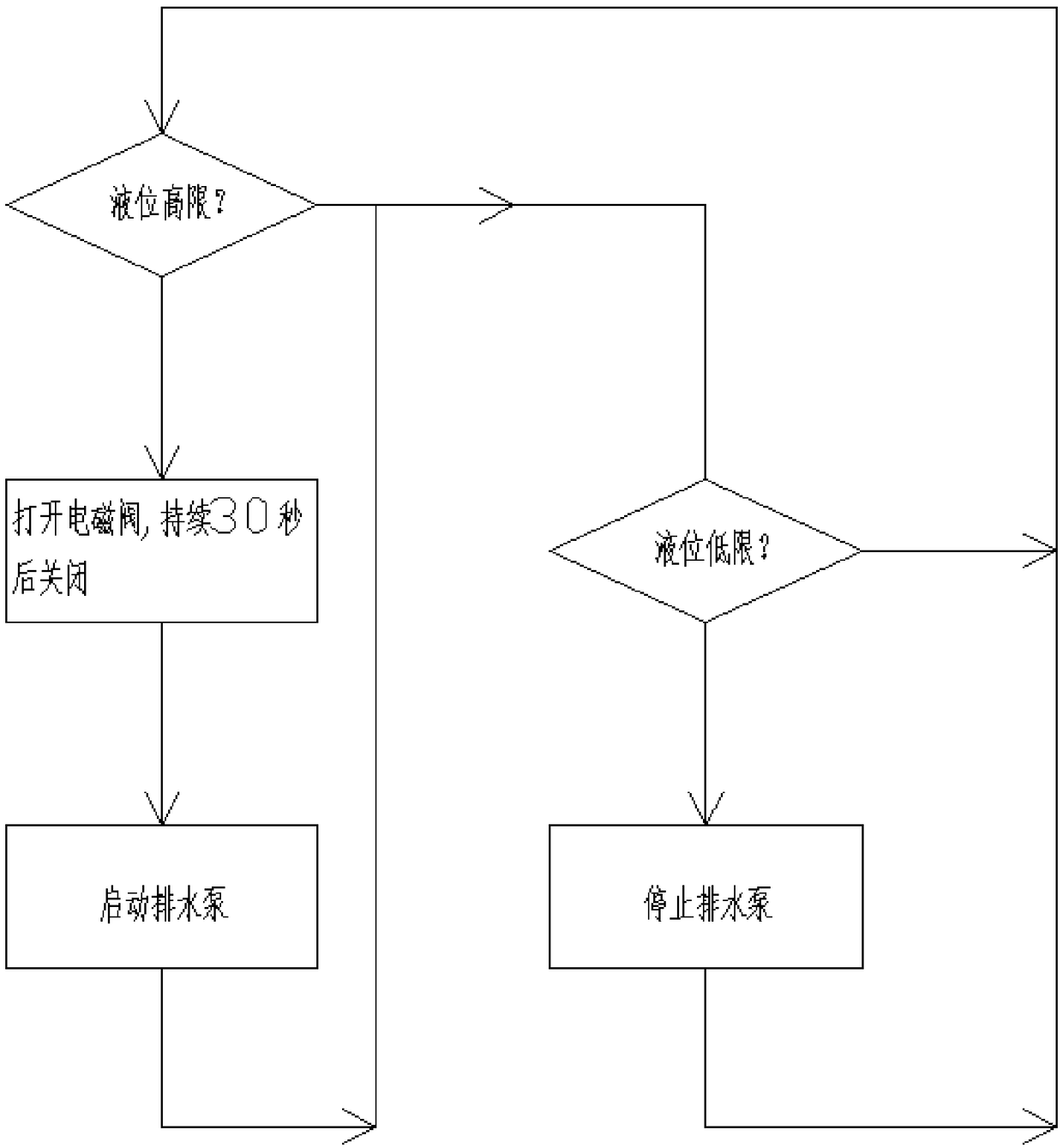

[0026] In order to facilitate automatic control, both the underground tank and the water supply tank are equipped with electronic water level sensors. Both electronic water level sensors output water level signals to the controller, and the controller outputs drive signals to the pump and the first valve and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com