Cooling system capable of achieving automatic liquid injection function and automatic liquid injection method

A technology of cooling system and coolant, which is applied in the direction of control/regulation system, cooling/ventilation/heating renovation, refrigeration machine, etc., which can solve the problems affecting the utilization rate of equipment, affecting the operation of electrical equipment, and cumbersome operation process, so as to improve heat dissipation Efficiency and equipment utilization, reduction of labor maintenance and maintenance costs, and the effect of simplifying the injection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

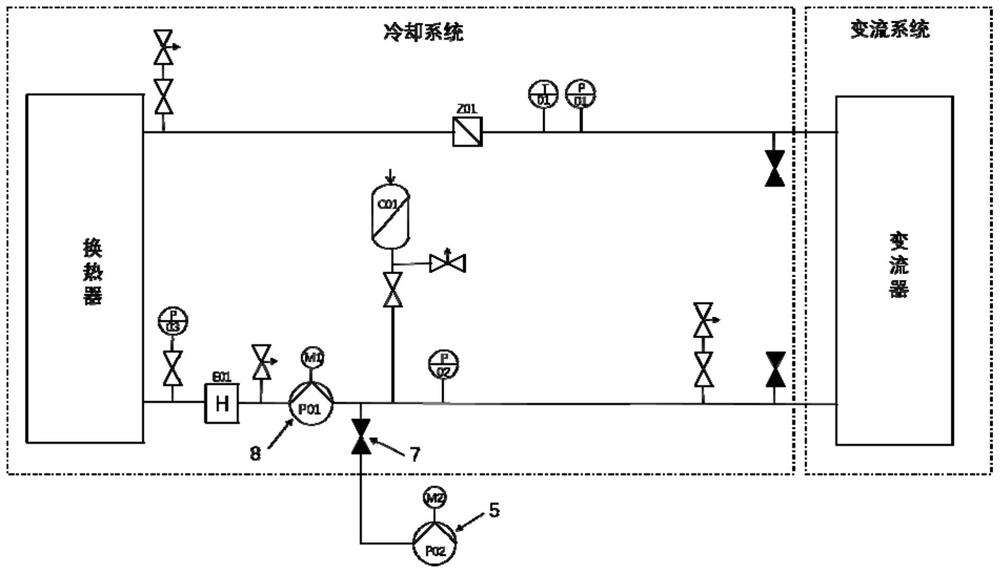

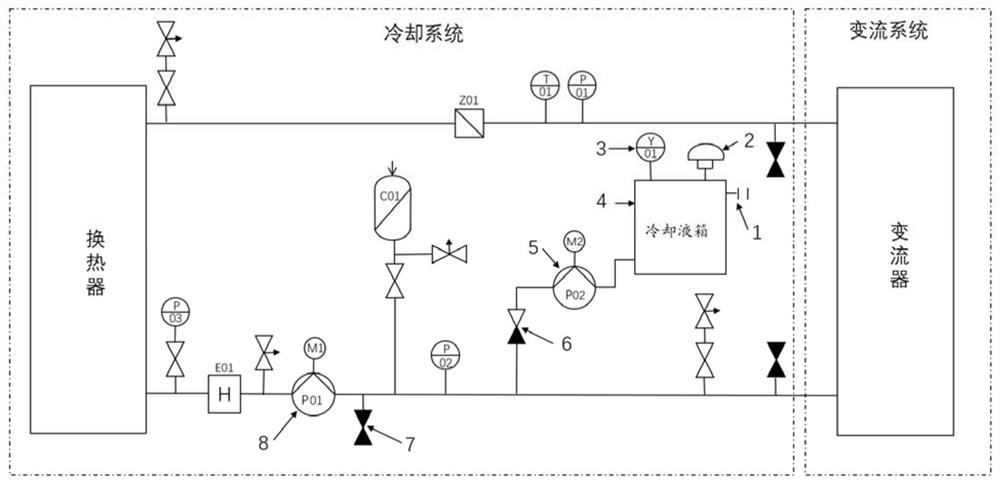

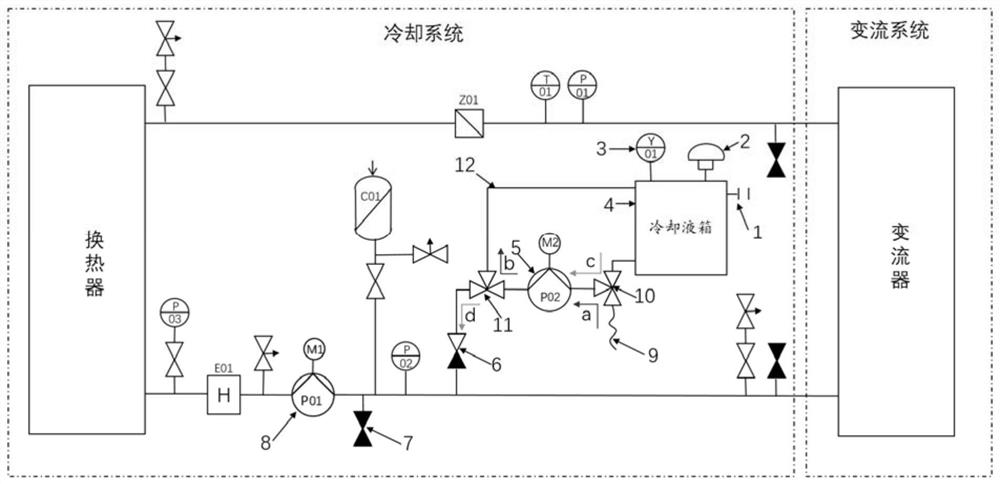

[0052] For a more detailed and complete description of the present invention, reference may be made to the accompanying drawings and the following various embodiments, in which like numerals represent the same or similar components. On the other hand, well-known components and procedures have not been described in the embodiments in order not to unnecessarily limit the present invention. In addition, for the purpose of simplifying the drawings, some well-known and conventional structures and elements are shown in a simplified and schematic manner in the drawings.

[0053] According to a preferred embodiment of the present invention, see figure 2 , a cooling system capable of realizing automatic liquid injection function is provided, comprising a heat exchanger, a converter and a liquid cooling pipeline connecting the heat exchanger and the converter. The liquid cooling pipeline is also provided with a circulating pump 8 . The cooling system further includes: a cooling liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com