Planetary carrier base of clutch

A planetary gear bracket and clutch technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of high processing cost, complex production process, etc., and achieve short welding time, simple processing technology, etc. Simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further illustrate the present invention below in conjunction with accompanying drawing.

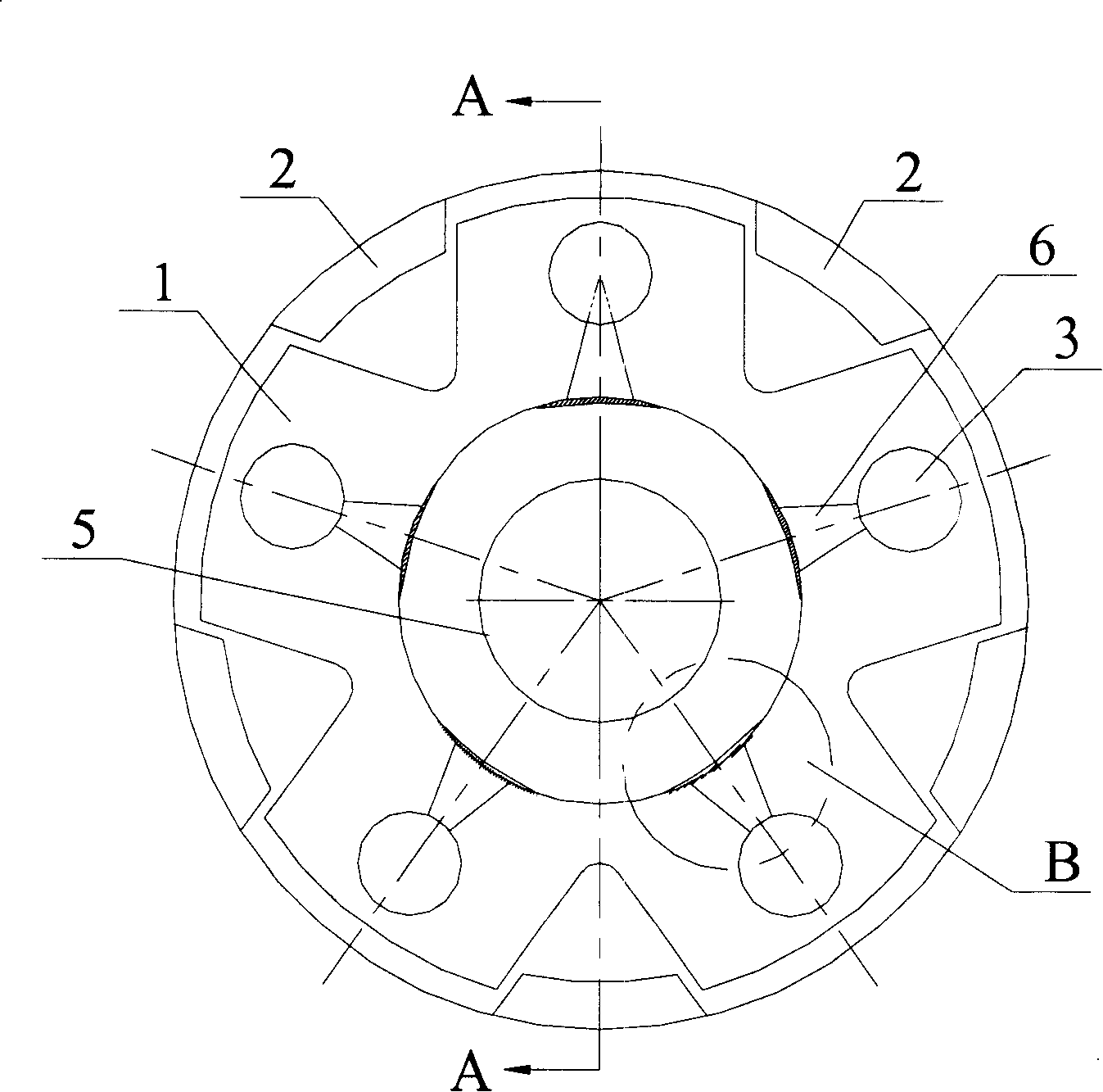

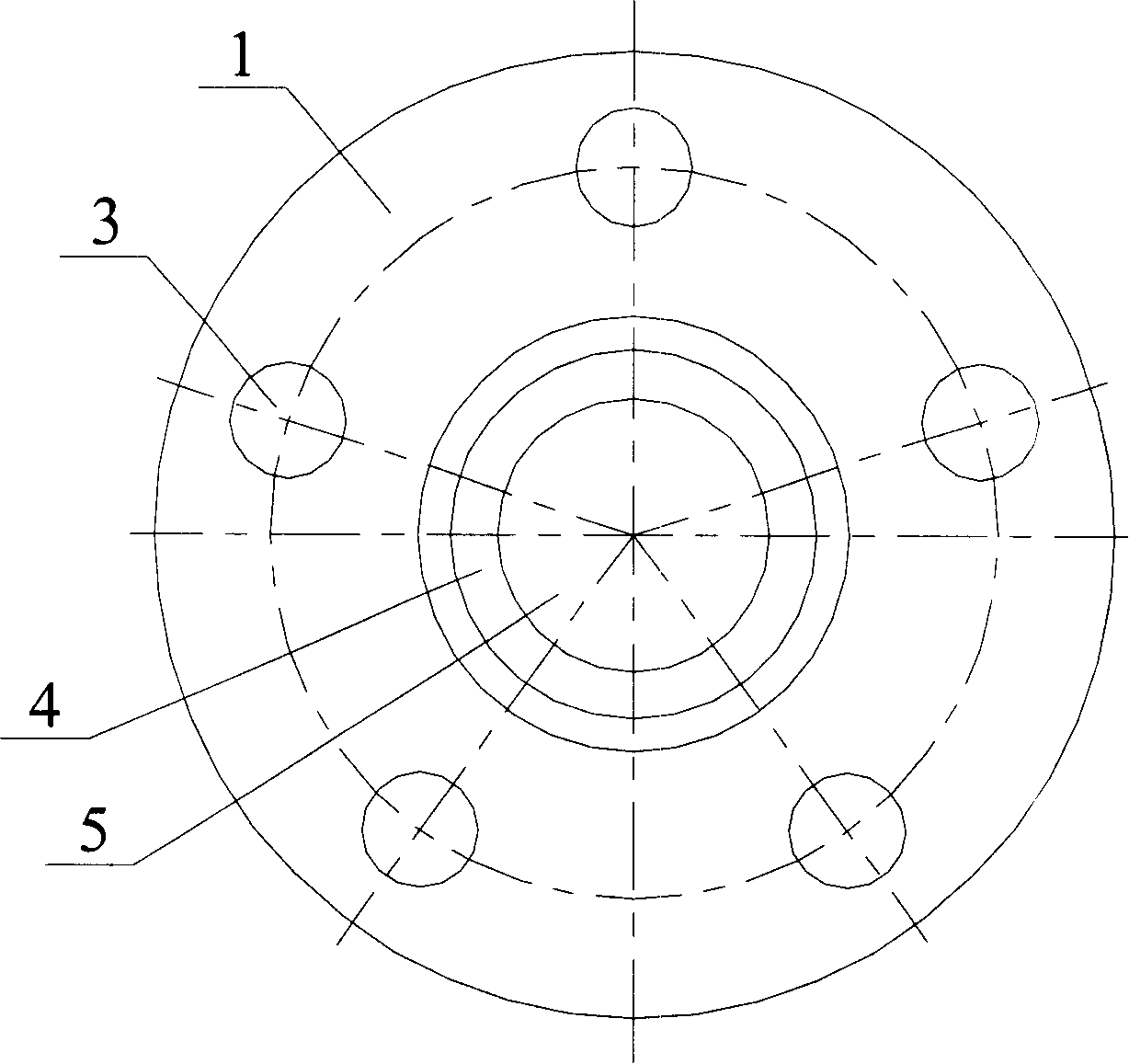

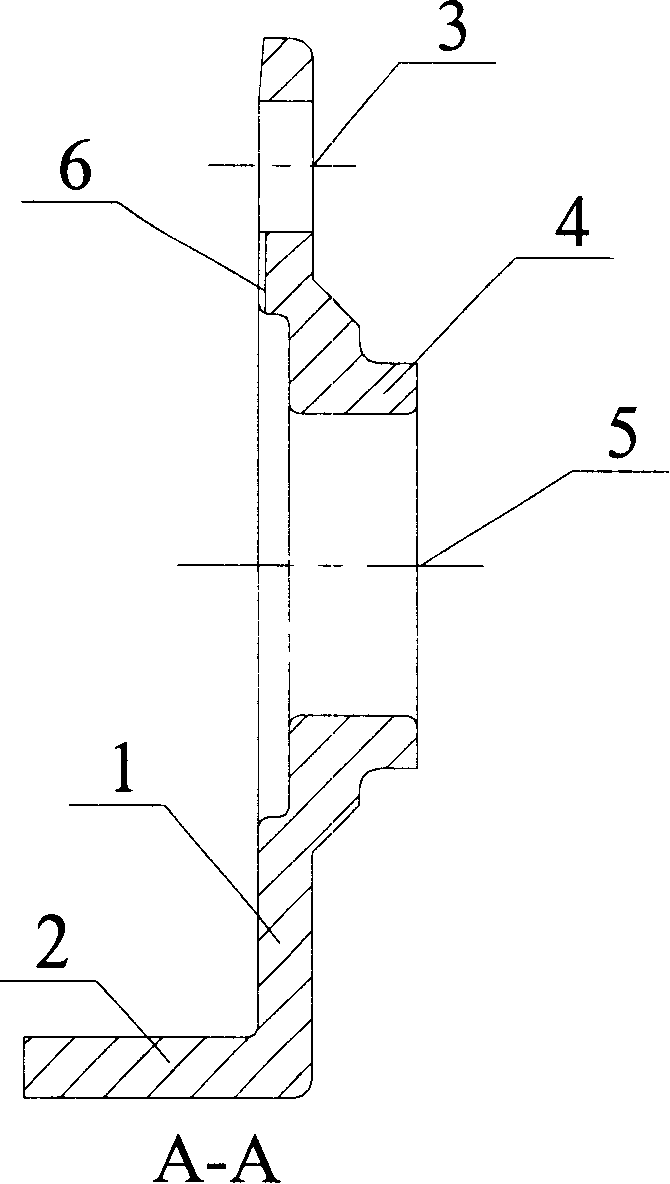

[0017] Such as Figure 1~3 As shown, the clutch planetary wheel bracket seat of the present invention is an integral component, including a circular bracket body 1 and a number of supporting feet 2, and the supporting feet 2 extend upward from the outer edge of the bracket body 1 and are uniformly arranged on the bracket body arc-shaped legs, the main body of the bracket 1 is evenly provided with planetary wheel holes 3, the center of the main body of the bracket is provided with a boss 4 protruding in the opposite direction of the supporting foot 2, and the center of the boss 4 is provided with a center Hole 5, the inner wall of the central hole 5 is provided with internal splines.

[0018] There are 3 to 5 supporting feet 2 , and 3 to 5 planetary wheel holes 3 , and the planetary wheel holes 3 and supporting feet 2 are alternately arranged on the bracket main body 1 at interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com