Cooling water warning device of vacuum pump of laminating machine

A technology of alarm device and vacuum pump, applied in the direction of lamination, control lamination, layered products, etc., can solve the problems of easy falling off of the connection between the cooling water pipe and the vacuum pump, air bubbles, falling of components, etc., so as to reduce the frequency of inspections and eliminate overheating. Operational risks and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

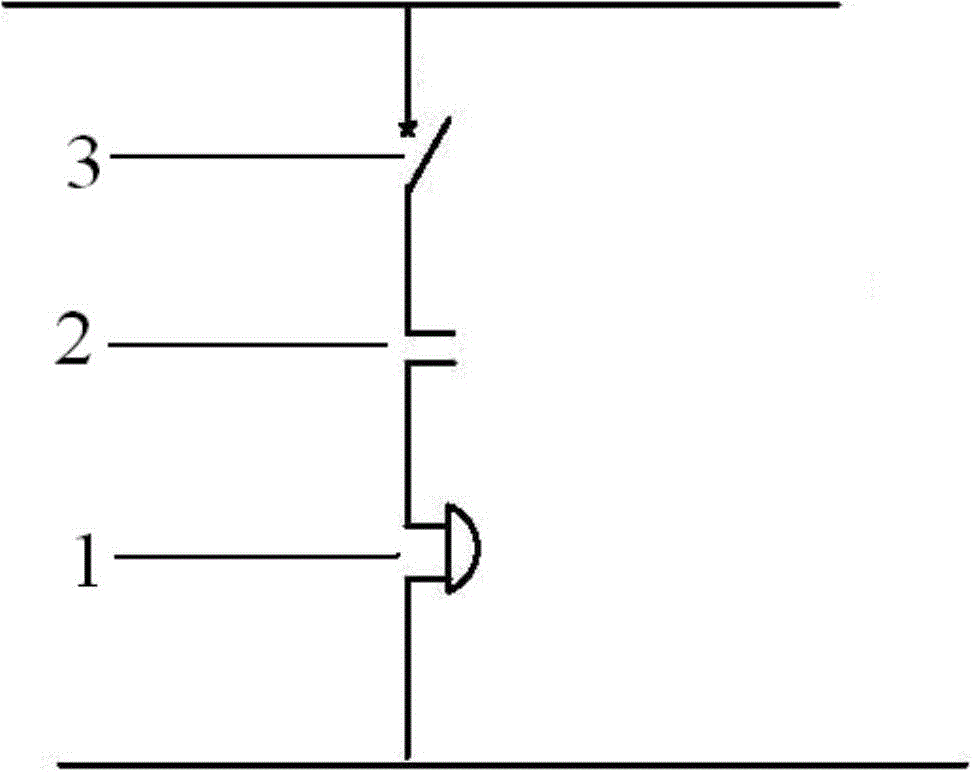

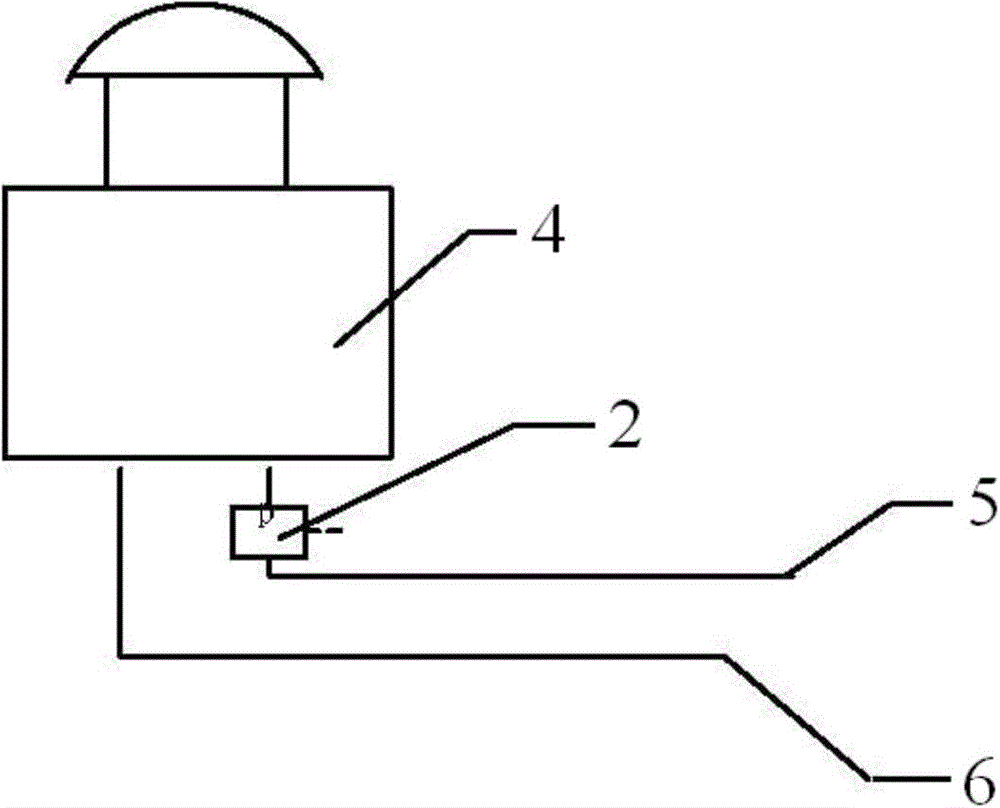

[0020] A laminator vacuum pump cooling water alarm device, its structure is as follows Figure 1-2 As shown, the vacuum pump 4 is connected, and the alarm device is a closed circuit composed of an air switch 3, a pressure relay 2 and a buzzer 1 connected in series through wires, and 220V alternating current is applied to the closed circuit. The air switch 1 used is a single-connected air switch, which is arranged in the electric control cabinet of the laminator. The pressure relay 2 used is a plunger type pressure relay with a pressure rating of 0.6Mpa. The vacuum pump 4 is connected to the water inlet pipe 5 through the pressure relay 2. In addition, the vacuum pump 4 is also connected to the water outlet pipe 6. The pressure of the liquid is used to open and close the electric contactor. When the pressure reaches or drops to the set value of the pressure relay 2, an electrical signal is sent to make the connected electrical components, such as electromagnets, motors, time re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com