Calibration method for six-row roller slewing bearings used in thousand-ton all-terrain cranes

A technology of slewing bearings and six rows of rollers, applied in roller bearings, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

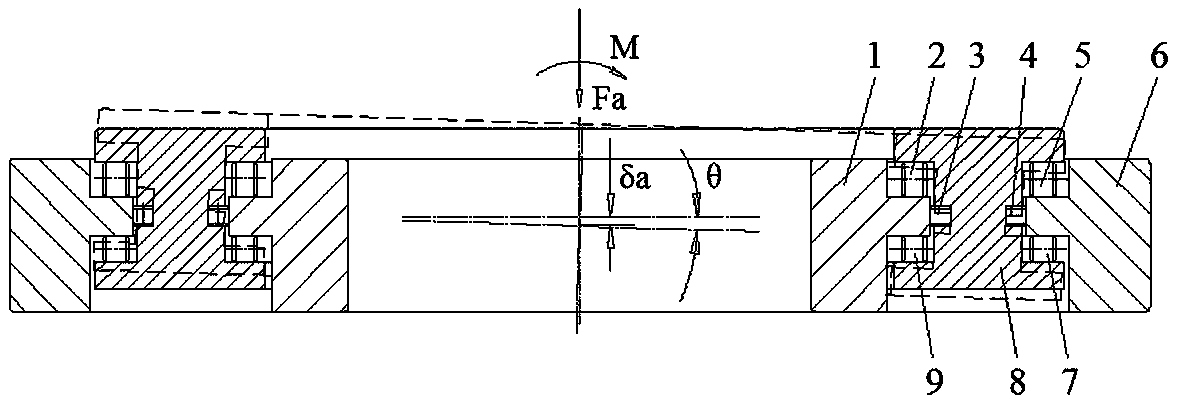

[0038] A six-row roller slewing bearing for a 1200-ton all-terrain crane, such as figure 1 As shown, it mainly consists of inner ring 1, upper row of inner ring rollers 2, radial inner ring rollers 3, radial outer ring rollers 4, upper row of outer ring rollers 5, outer ring 6, lower row of outer ring rollers Sub 7, middle ring 8, lower row inner ring roller 9 constitute.

[0039] The main structural parameters of the slewing bearing are as follows:

[0040] ① Upper row of inner ring rollers

[0041] pitch circle diameter (mm), roller diameter (mm), roller length (mm), the number of rollers (indivual)

[0042] ② Upper row of outer ring rollers

[0043] pitch circle diameter (mm), roller diameter (mm), roller length (mm), the number of rollers (indivual)

[0044] ③ Lower row of inner ring rollers

[0045] pitch circle diameter (mm), roller diameter (mm), roller length (mm), the number of rollers (indivual)

[0046] ④ Lower row of outer ring roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com