Asymmetric coarse taper structure few-mode fiber strain sensor

A strain sensor and few-mode optical fiber technology, applied in the field of optical fiber, can solve problems such as low sensitivity and inability to fully reflect, and achieve broad application prospects, compact structure, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

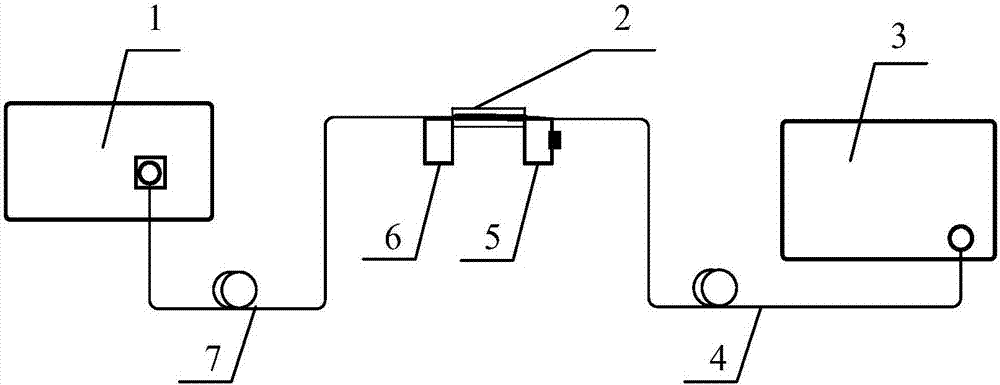

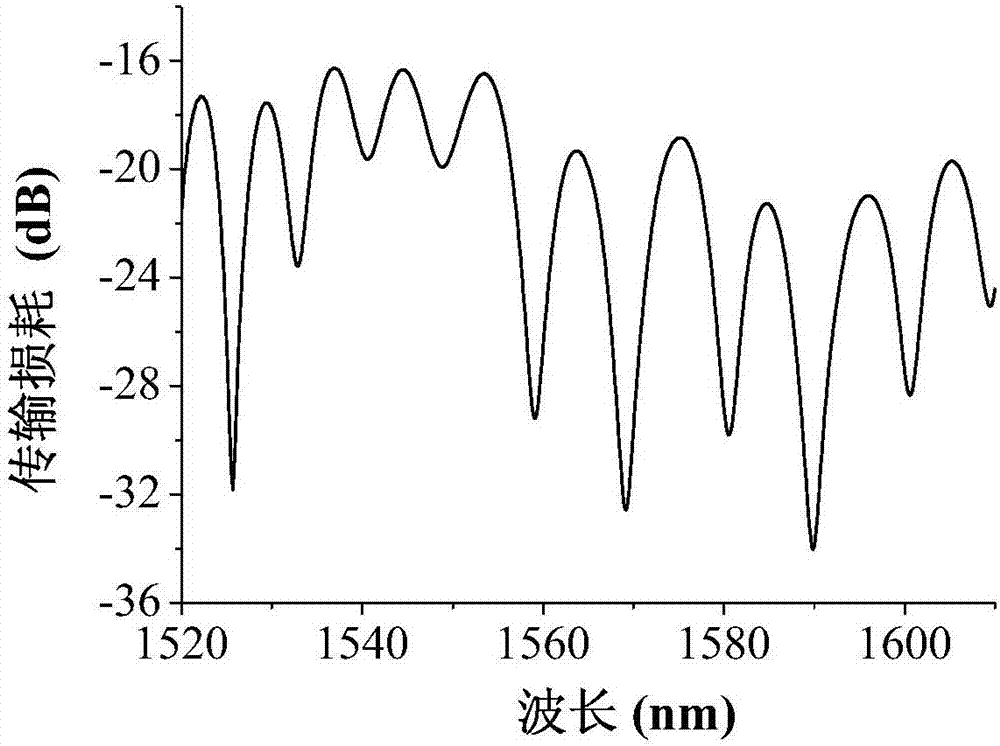

[0028] like figure 1 As shown, one end of the sensing unit 2 is connected to the broadband light source 1 by introducing a single-mode optical fiber 7, and the other end of the sensing unit 2 is connected to the spectrometer 3 by exporting a single-mode optical fiber 4, and the sensing unit 2 is arranged on the tensile test plane , the tension test platform includes the fixed end 5 of the test platform and the mobile end 6 of the test platform. In the experiment, the position of the test platform 5 is adjusted to adjust the tension on the optical fiber, and the transmission spectrum under the corresponding tension is recorded from the spectrometer 3, as shown in Figure 4 shown.

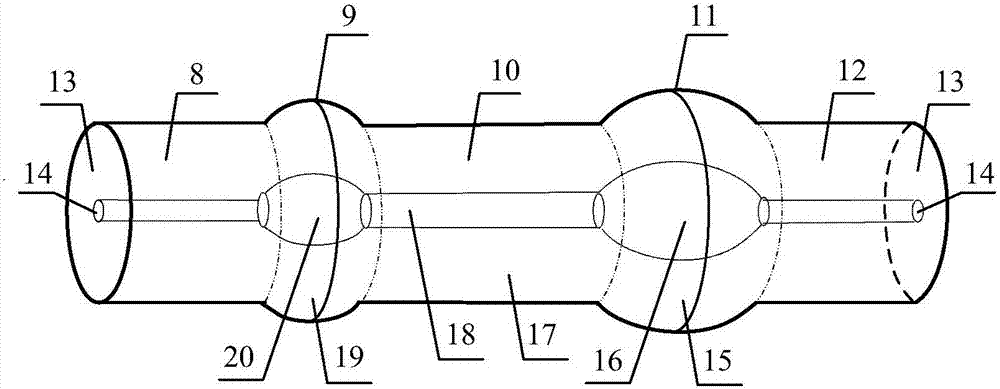

[0029] like figure 2 As shown, the sensing unit 2 includes an incident single-mode fiber 8, a few-mode fiber 10 and an outgoing single-mode fiber 12, one end of the incident single-mode fiber 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com