Overhaul the power box

A technology for overhauling power supply and power supply room. It is applied to electrical components, emergency protection circuit devices, substation/switch layout details, etc. It can solve problems such as lack of safety interlocks and difficult wiring of power supply boxes. The effect of large contact and contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

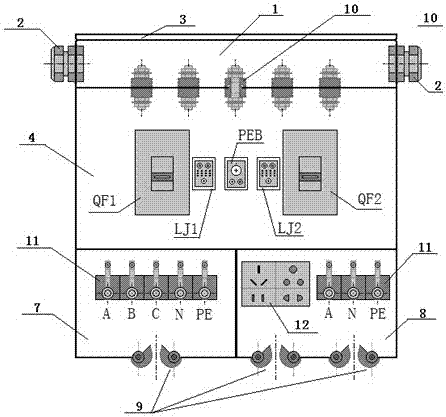

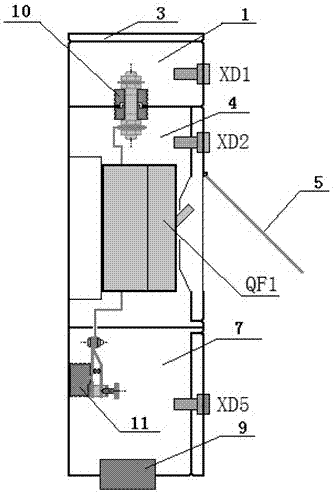

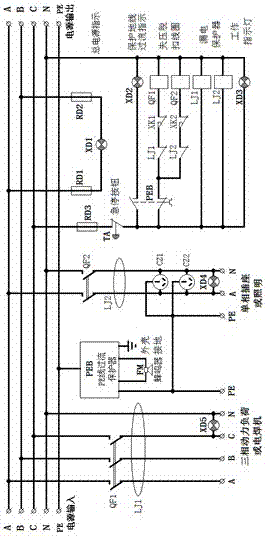

[0041] see Figure 1 to Figure 7 , the maintenance power supply box of the present invention comprises a box body, and the top of the box body is provided with a cover plate 3; the box body is divided into a power supply chamber 1, a switch chamber 4, a power terminal chamber 7 and a socket terminal chamber 8; the power supply chamber The cable joints 2 on the left and right sides of 1 are respectively connected to the incoming cable 13-1 and the outgoing cable 13-2, the power supply room 1 is provided with a through-core insulator 10, and the front panel of the power supply room 1 is provided with a power supply room indicator Lamp XD1;

[0042] The front of the switch room 4 is provided with a switch room door 4-1, and the switch room door 4-1 is also provided with a reversible waterproof glass door 5; in the switch room 4, the waterproof glass door 5 After that, the air switch QF1, the leakage protector LJ1, the PE line overcurrent protector PEB, the leakage protector LJ2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com