Optical laminate for front surface of in-cell touch panel liquid crystal element and in-cell touch panel liquid crystal display device using same

一种液晶显示装置、光学叠层体的技术,应用在光学、光学元件、偏振元件等方向,能够解决厚度或重量增加等问题,达到防止白浊的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

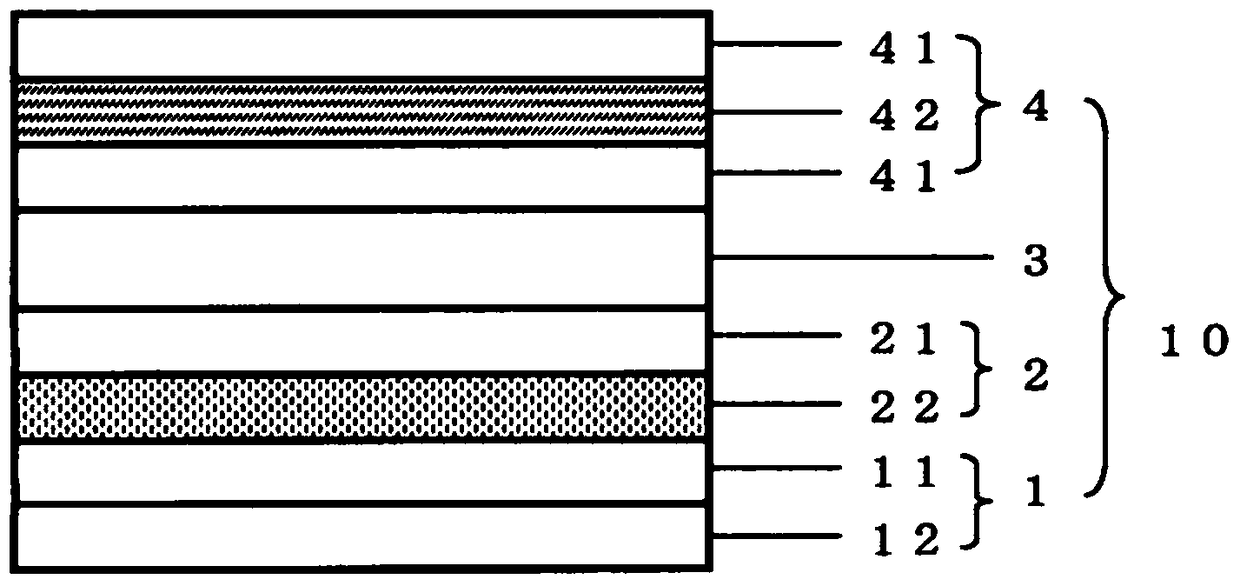

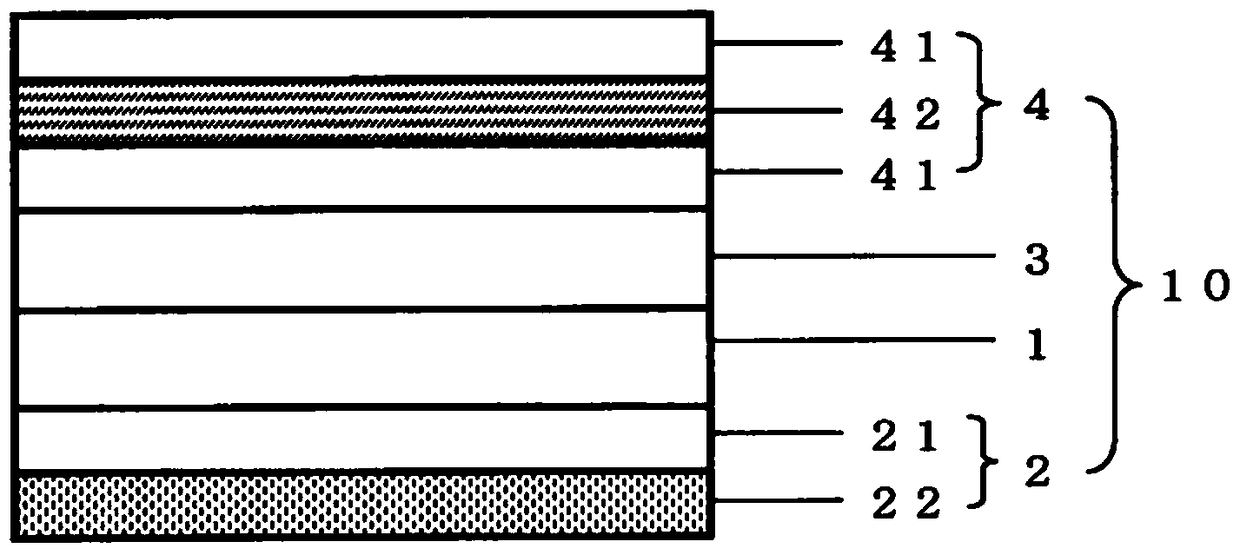

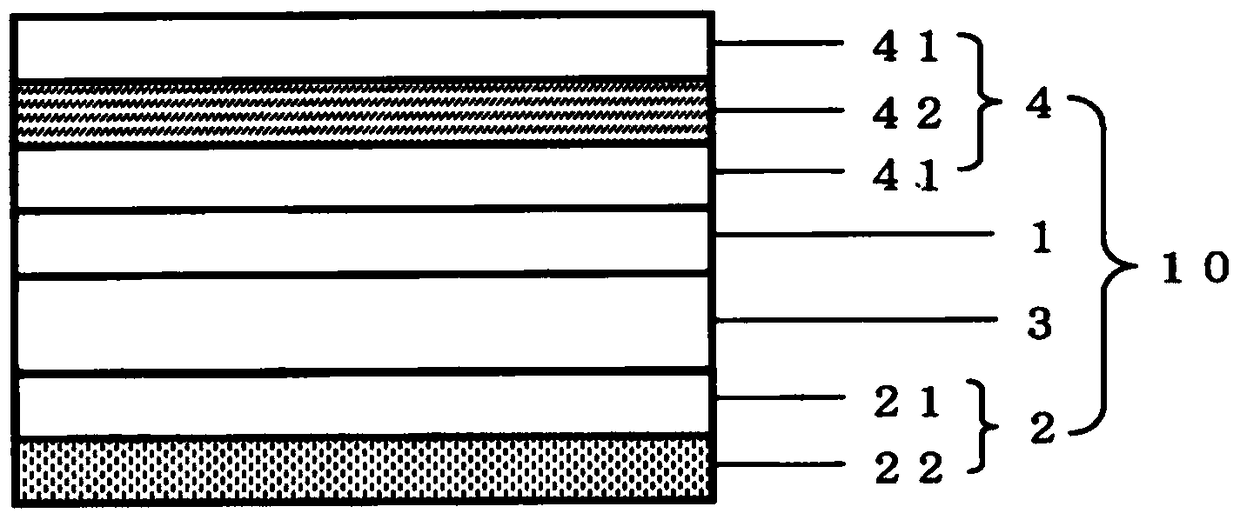

Image

Examples

Embodiment 1

[0239] (1) Production of surface protective film

[0240] [Adjustment of the coating solution for the cured layer for the outermost surface]

[0241] The pentaerythritol triacrylate (Nippon Kayaku Co., PET-30), polymer-containing acrylate resin (Arakawa Chemical Co., Beamset DK-1) and silica particle dispersion (JSR Co., KZ6406) The solid content of 3 components was added to methyl isobutyl ketone so that it might become 50 parts, 25 parts, and 25 parts in order, and it stirred, and obtained the solution a.

[0242] Next, with respect to 100 parts of the solid content of the solution a, 7 parts by mass of a photopolymerization initiator (manufactured by BASF Japan, Irgacure 184) and 1.5 parts by mass of a photopolymerization initiator (manufactured by BASF Japan, Lucirin TPO) were added and stirred and This was dissolved to prepare a solution b having a final solid content of 40% by mass.

[0243] Next, 0.4 parts of a leveling agent (product name MegaFuck RS71, manufactured by DIC Co...

Embodiment 2

[0257] On the conductive layer (first conductive layer) of Example 1, except that the second conductive layer was formed by the following method, the same procedure as in Example 1 was carried out to produce an optical laminate.

[0258] (Formation of the second conductive layer)

[0259] Pentaerythritol triacrylate (PETA) and HRAG acrylic (25) MIBK (thermoplastic resin) manufactured by DNP Fine Chemicals Co., Ltd. were added to methyl ethyl ketone (MEK) so that the solid content of the above 2 components became 70 parts and 30 parts. ) / Isopropanol (IPA) mixed solvent and stirred and dissolved to obtain solution e.

[0260] Next, to 100 parts of the solid content of the solution e, 4 parts by mass of a photopolymerization initiator (manufactured by BASF Japan, Irgacure 184) and 0.2 part of a leveling agent (manufactured by Dainichi Seiki Kogyo Co., Ltd., 10-301 (TL)) were added And stirring to prepare solution f.

[0261] Next, to 100 parts by mass of the resin component of the solut...

Embodiment 3

[0264] In Example 1, the conductive layer (first conductive layer) was formed on the surface protective film instead of the retardation film, and the conductive layer side of the surface protective film and the polarizing film were bonded together, except that it was the same as in Example 1. Operation to produce an optical laminate. In addition, regarding Example 3, before bonding a surface protection film and a retardation film, the same grounding process as Example 1 was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com