Curable composition

A composition, compound technology, applied in the direction of non-polymer organic compound adhesives, adhesive types, ester copolymer adhesives, etc., can solve the degradation of step absorption and step embedding characteristics, reduce OCR or OCA optics characteristics, increase in stamping characteristics, etc., to achieve the effects of improving stamping performance and handling characteristics, excellent step absorption, and suppressing white turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0169] Preparation of polymer components

[0170]2-Ethylhexyl acrylate (EHA), 2-hydroxyethyl acrylate (HEA), 2-ethylhexyl methacrylate (EHMA), acrylamide (AAm) and isobornyl acrylate (IBoA) were prepared as follows The ratio of 80 parts by weight: 6 parts by weight: 7 parts by weight: 4 parts by weight: 3 parts by weight (EHA:HEA:EHMA:AAm:IBoA) shown in Table 4 was introduced to make nitrogen reflux and a cooling device was installed so that the temperature Controlled 2L reactor to form monomer mixture. Subsequently, nitrogen was purged for 1 hour to remove oxygen, and with respect to 100 parts by weight of the monomer mixture, introduced thereto in an amount of about 0.03 parts by weight diluted in ethyl acetate while the temperature was raised to about 67°C. AIBN (azobisisobutyronitrile) to a concentration of 50% by weight, and then reacted for 8 hours to prepare a slurry-type polymer component having a weight average molecular weight (Mw) of about 109,000 or so.

[0171...

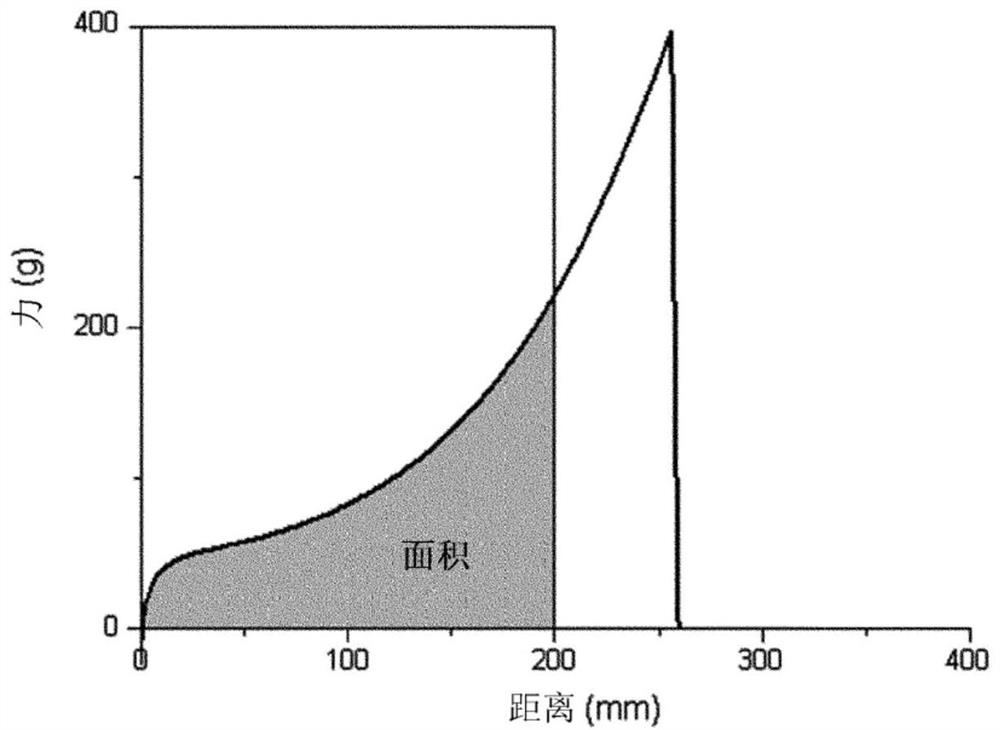

Embodiment 2

[0174] A polymer component having a weight-average weight (Mw) of about 85,000 was prepared in the same manner as in Example 1, except that the type and ratio of the monomers in preparing the polymer component were adjusted as shown in Table 4 below, and Using this, a pressure-sensitive adhesive layer and a pressure-sensitive adhesive film were prepared in the same manner. The stamping factor (F) measured on the pressure sensitive adhesive layer was around 68.4 gf / μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com