Patents

Literature

31results about How to "Suppress cloudiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

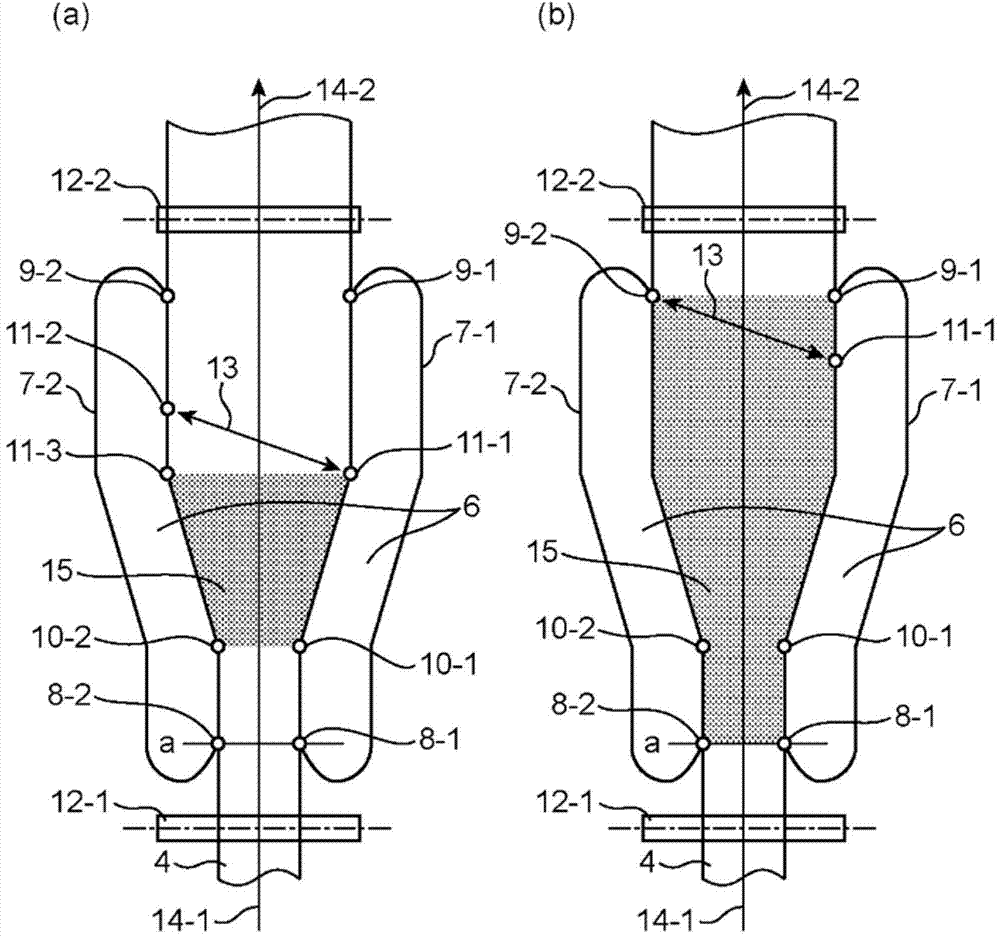

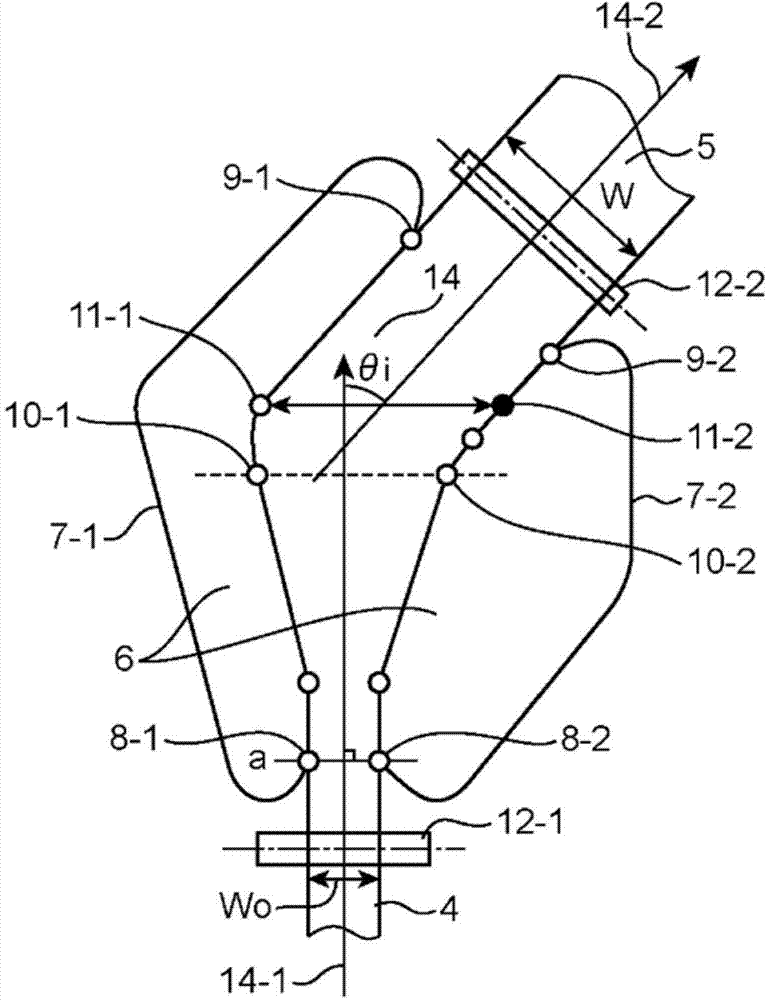

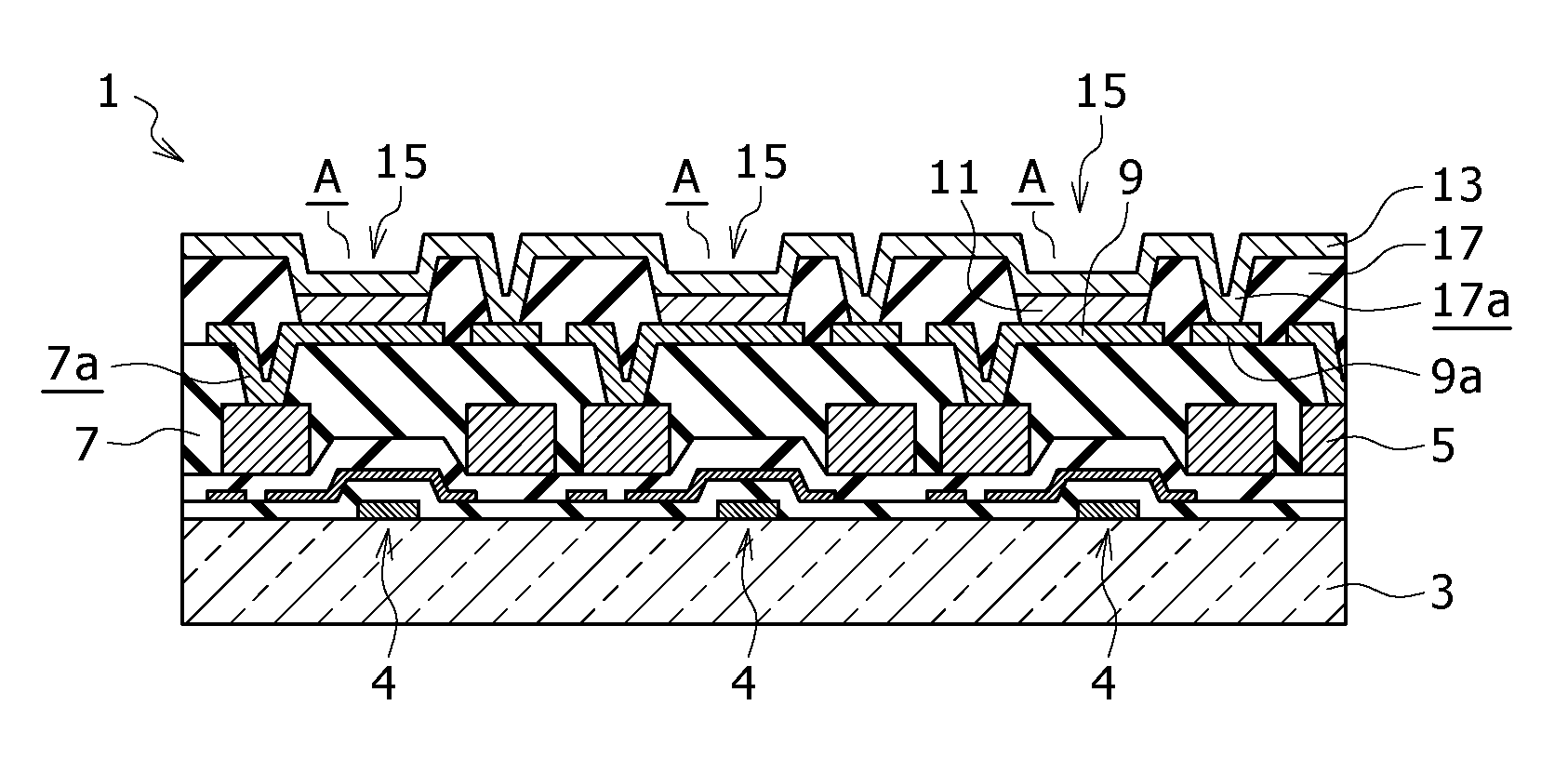

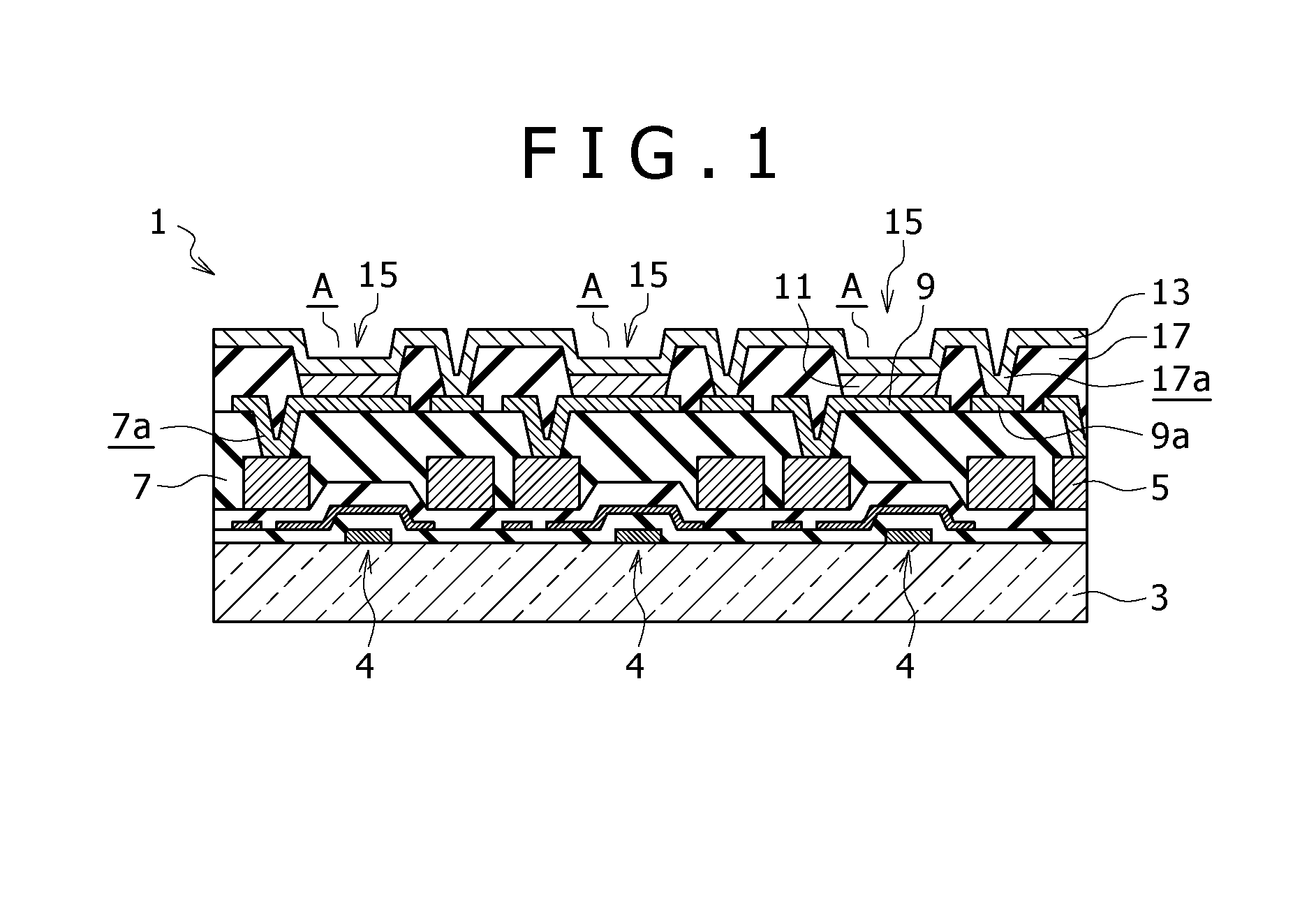

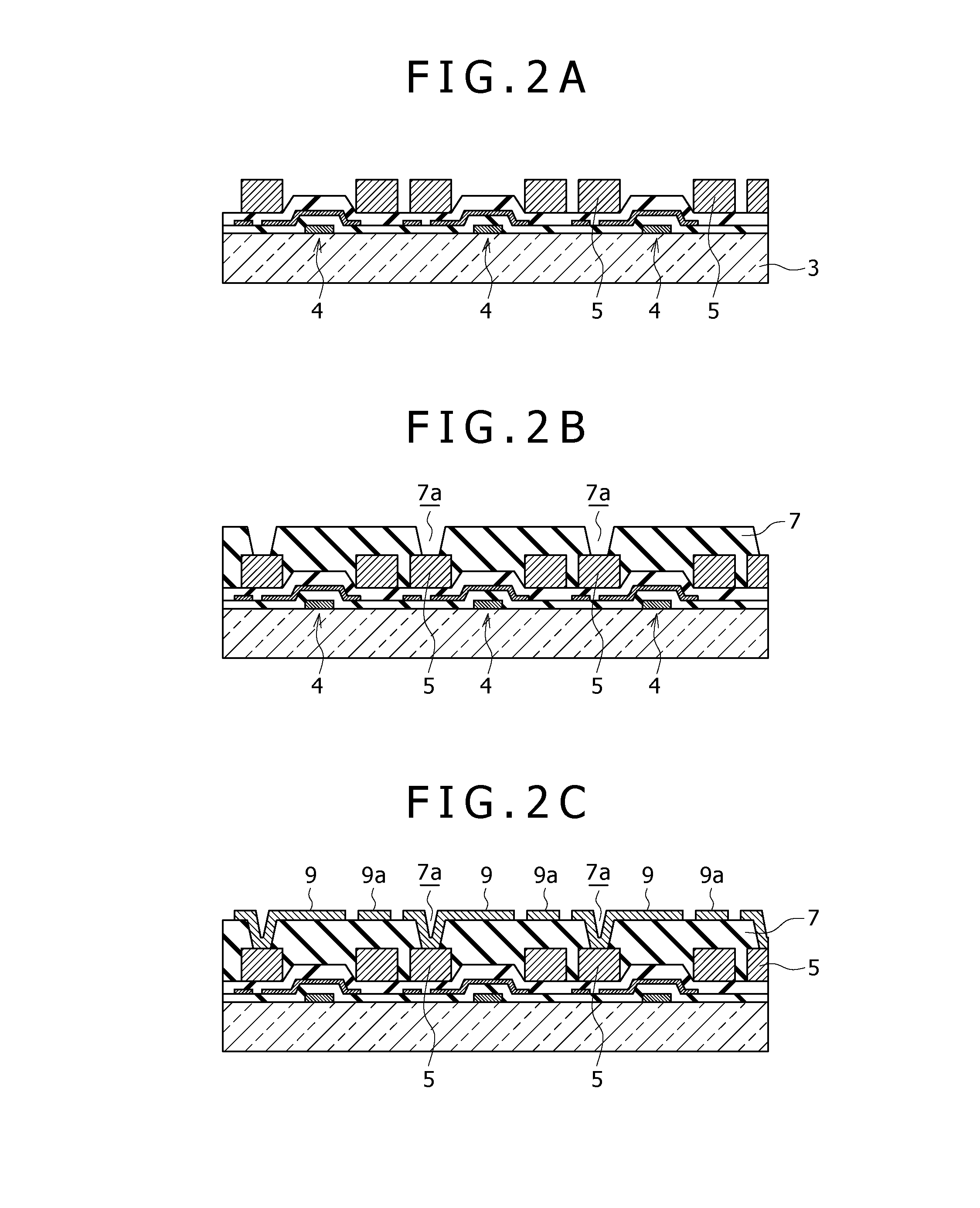

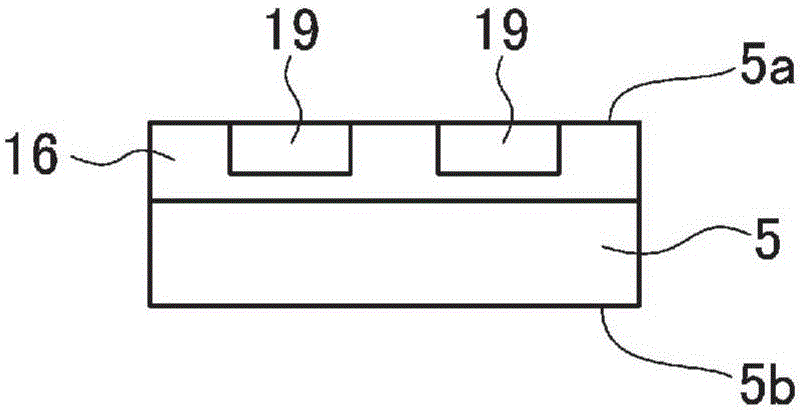

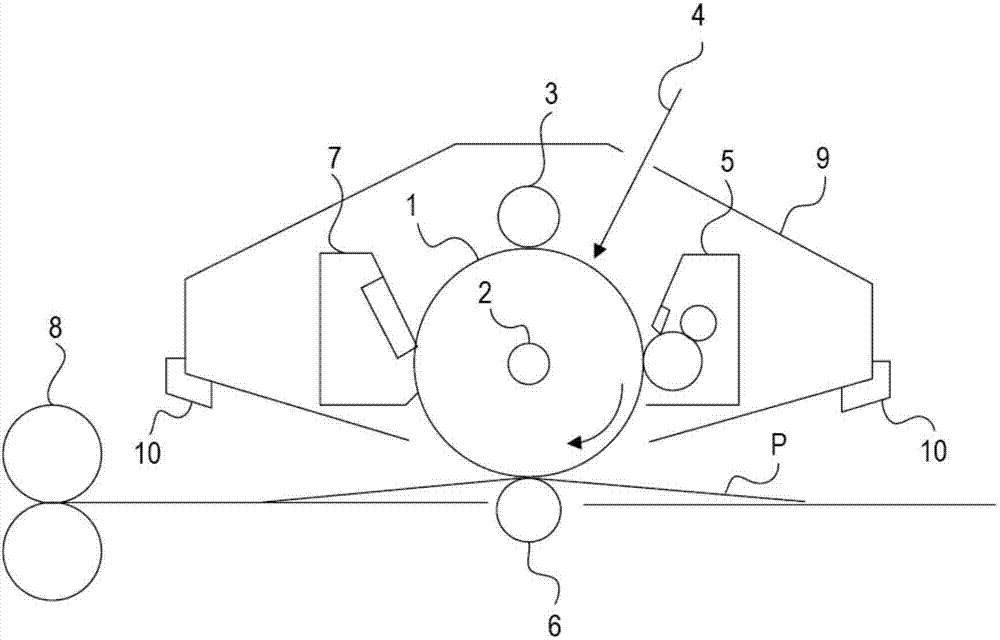

Method for manufacturing organic el display and organic el display

ActiveUS20090009068A1Avoid accumulationSuppress cloudinessDischarge tube luminescnet screensElectroluminescent light sourcesOrganic layerDisplay device

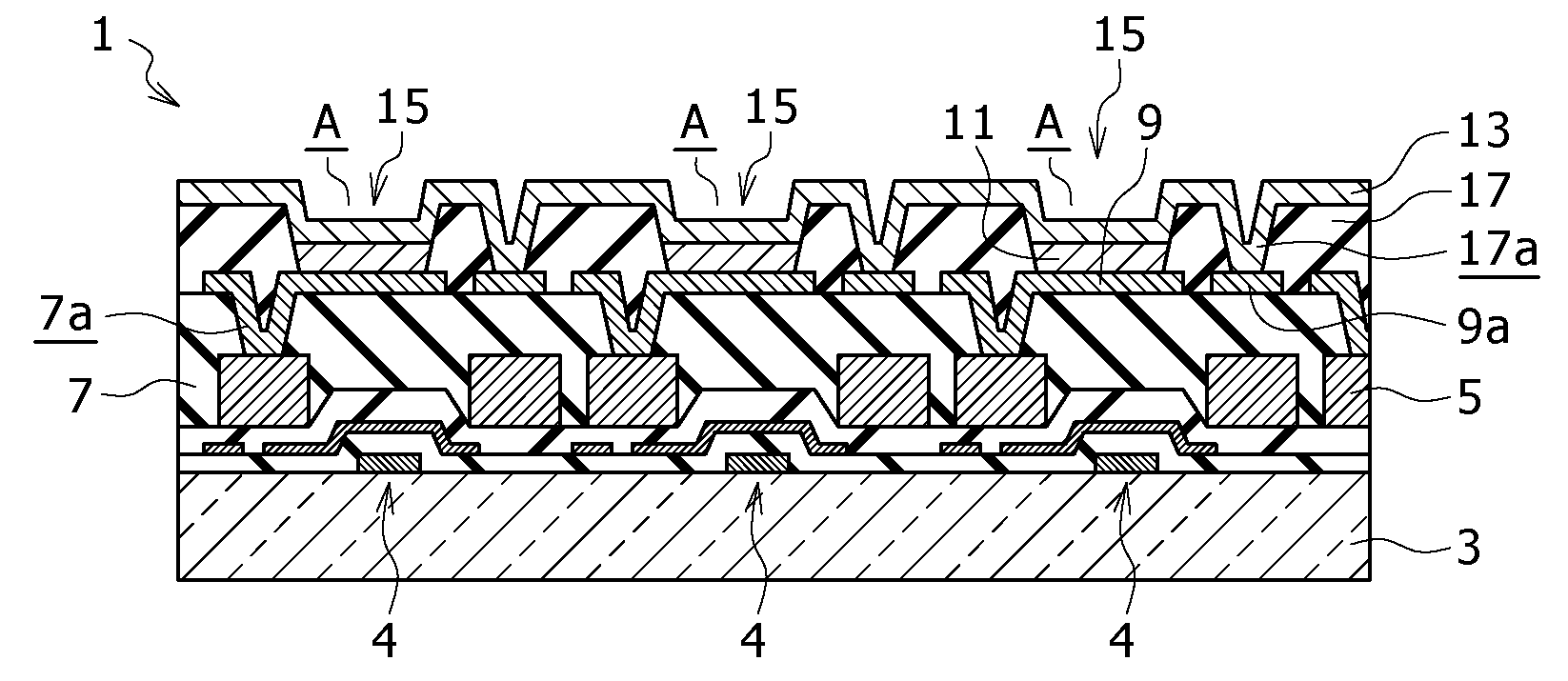

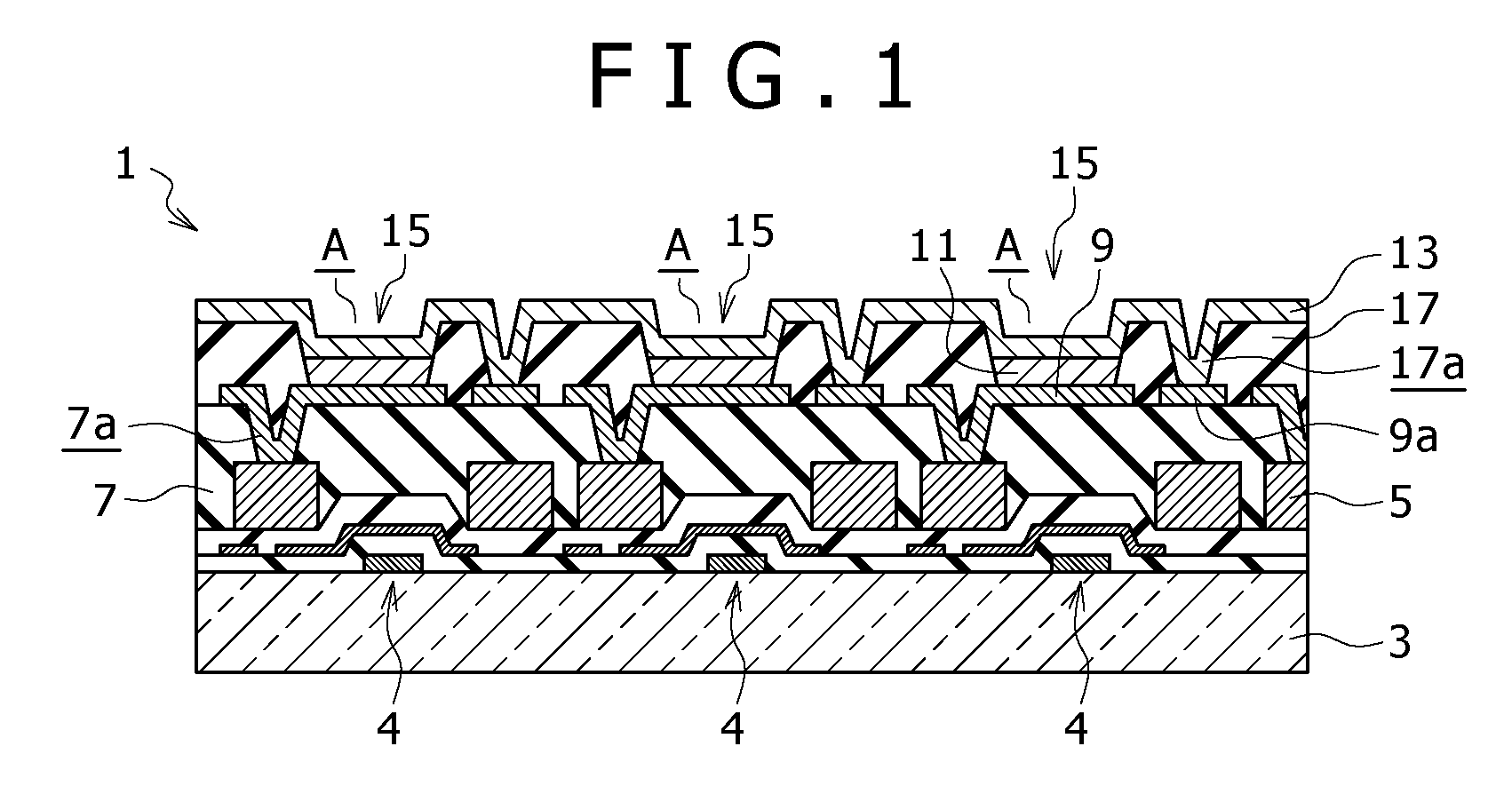

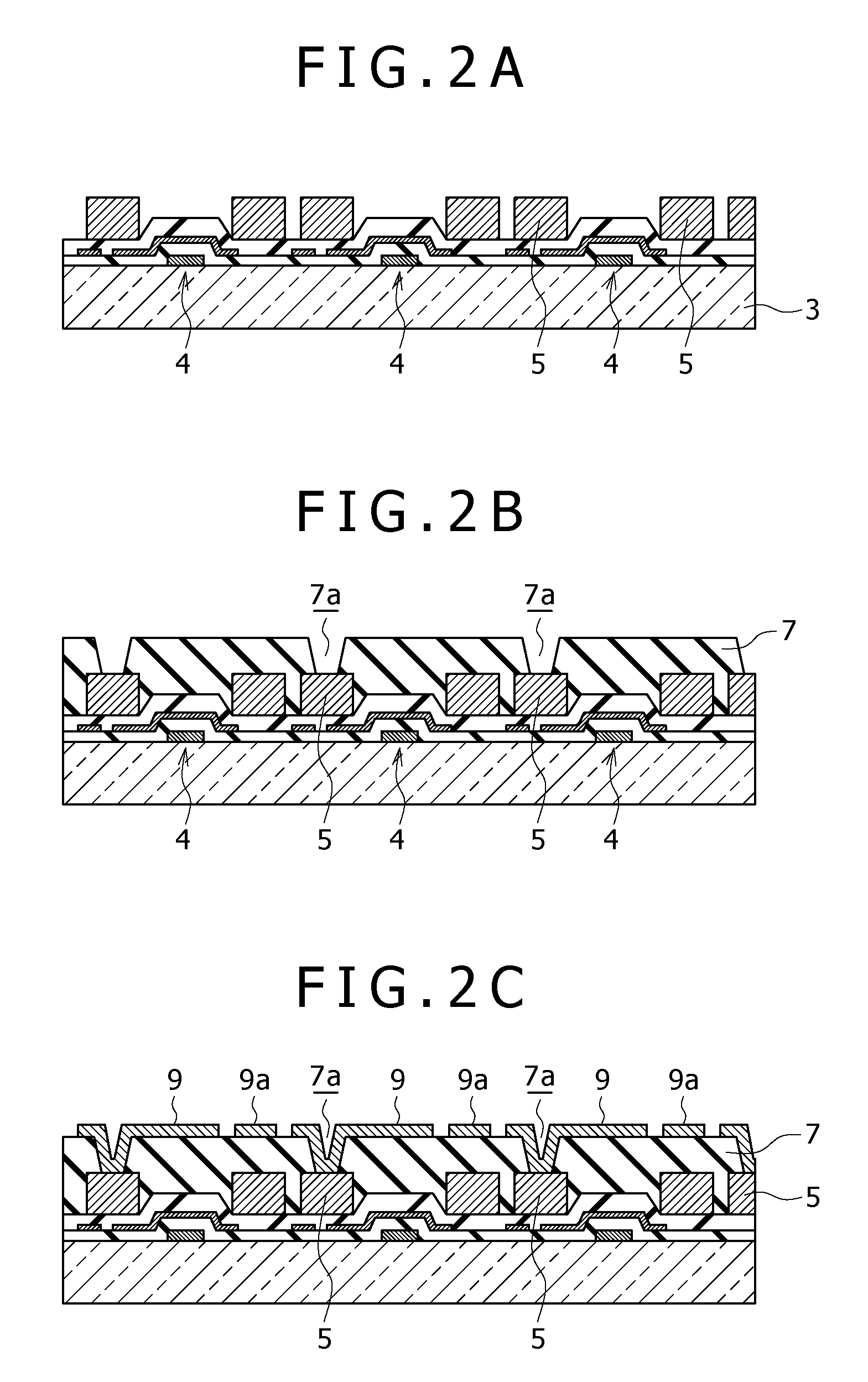

Disclosed herein is a method for manufacturing an organic electroluminescence display including multilayer structures that are each formed in a respective one of pixel areas in an effective area of a substrate and are each formed by a lower electrode, an organic layer, and an upper electrode, the organic electroluminescence display having a common electrode that electrically connects the pixel areas, the method including the steps of: forming a protective electrode and an outer-peripheral electrode that are electrically connected to the common electrode; forming the multilayer structures; and carrying out film deposition treatment involving electrification of the substrate.

Owner:JOLED INC

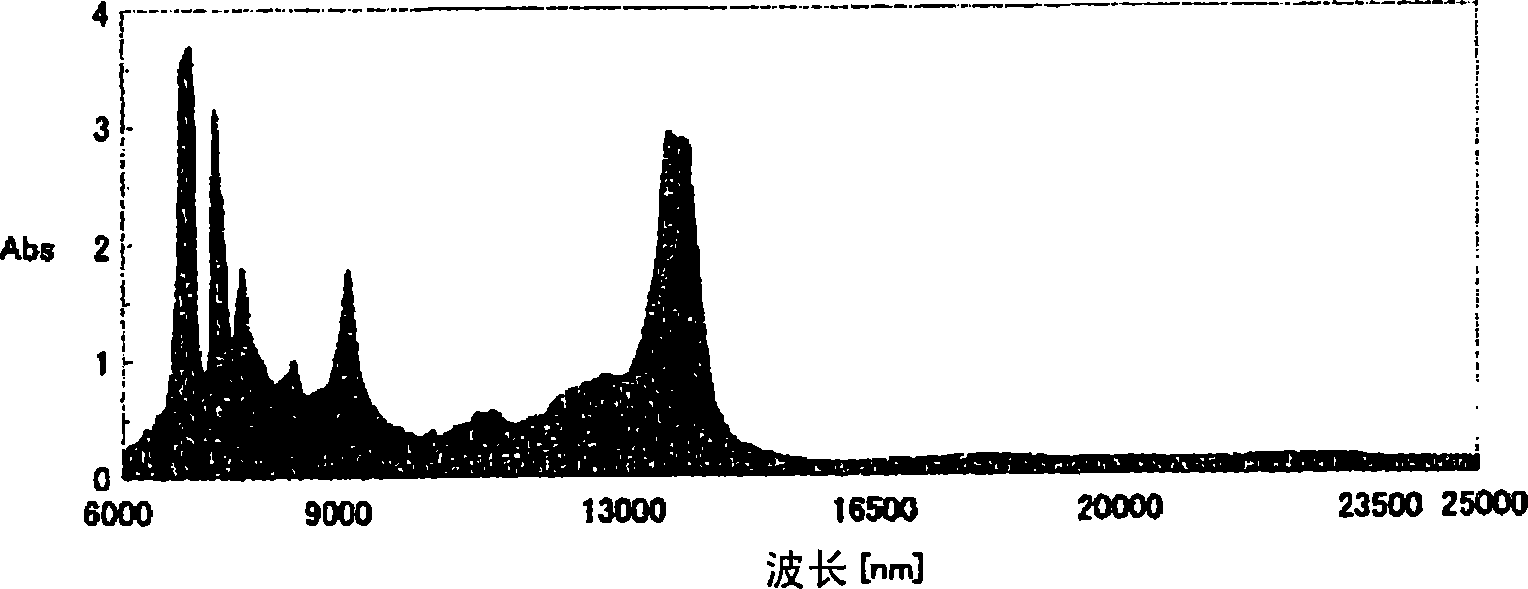

Optical element and method for producing the same

InactiveUS20100330378A1Suppress cloudinessImproved environmental durabilityGlass/slag layered productsSpecial surfacesFluorophosphate glassPhosphate glass

The present invention relates to an optical element comprising: a optical glass made of a phosphate glass or a fluorophosphate glass; and an optically functional film formed on a surface of the optical glass, wherein the optically functional film comprises two or more layers made of different materials, and the outermost surface layer thereof is made of a material(s) having low reactivity with phosphoric acid.

Owner:ASAHI GLASS CO LTD

Solvent-free urethane composition

ActiveCN1894299AReduce loadHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolSolvent free

A solvent-free composition is prepared, which is a composition comprising a polyol component (A) and a polyisocyanate component (B), wherein the polyol component (A) is composed of a low-molecular-weight polyol (A1) with a molecular weight of 350 or less. The viscosity of the aforementioned low-molecular polyol (A1) may be 500 mPa·s or less at 25°C. The aforementioned low-molecular polyol (A1) may be, for example, C2-6 alkylene glycol or the like. In addition, the polyol component (A) may be composed of a low-molecular polyol (A1) and a polymer polyol (A2) as a diluent. The aforementioned polyisocyanate component (B) may be a modified product or a derivative of polyisocyanate (for example, a multimer of diisocyanate, etc.). The aforementioned solvent-free composition may further contain an epoxy group-containing compound (aliphatic diol glycidyl ether, aliphatic polyhydric alcohol glycidyl ether having a hydroxyl group, etc.) (C) that may have a hydroxyl group. Such a solvent-free composition has a small load on the environment, has excellent coating film properties, and has high application efficiency.

Owner:日本硅石株式会社

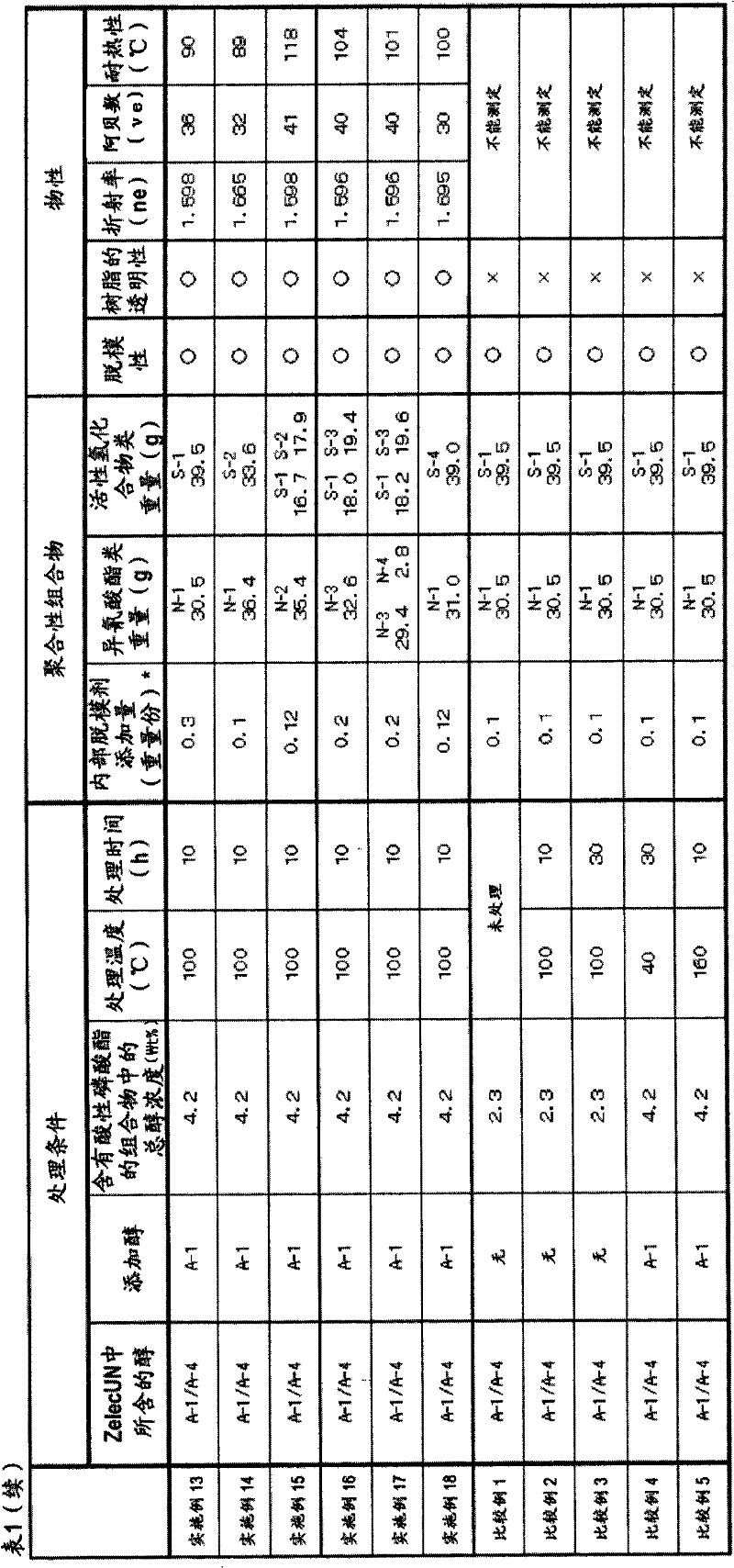

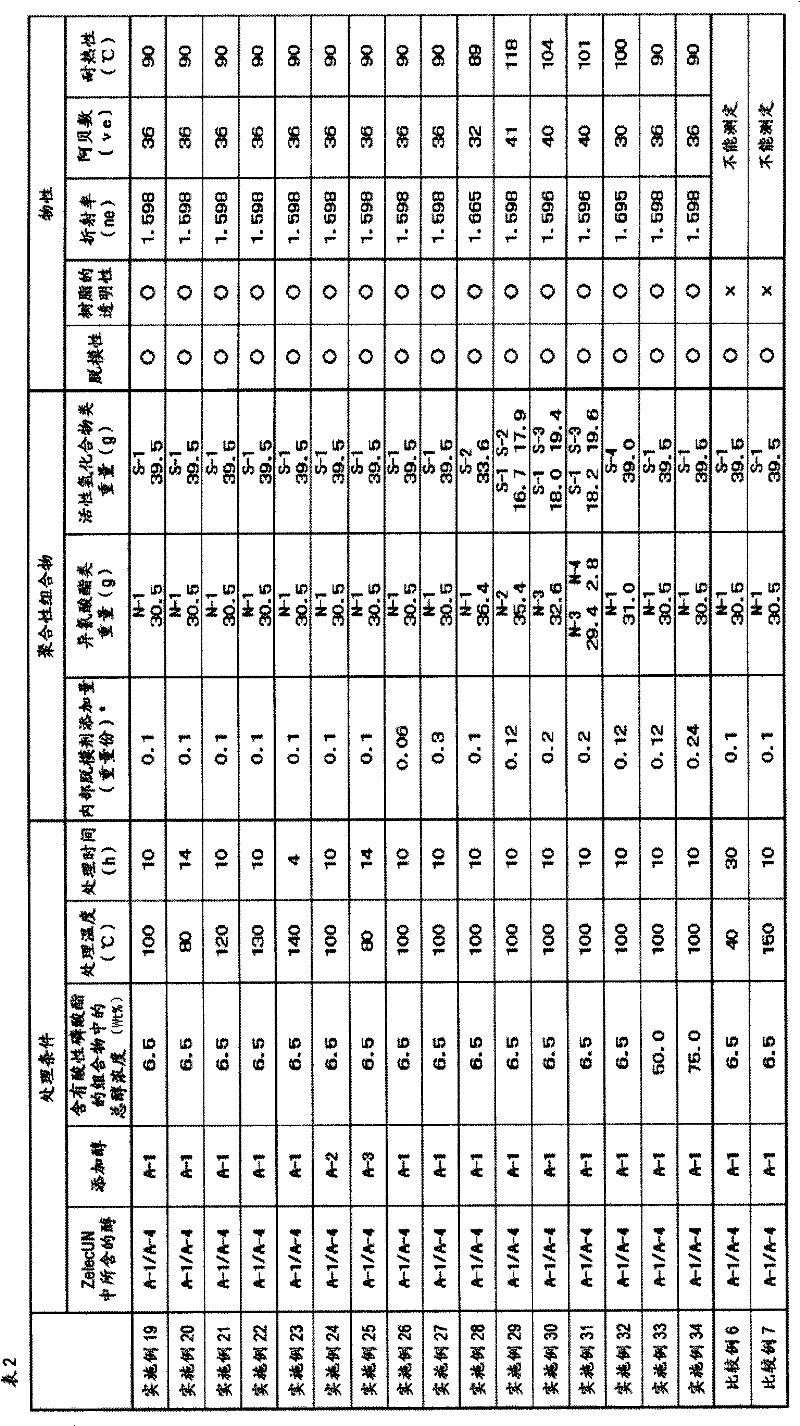

Method for producing internal mold release agent for optical material, internal mold release agent for optical material, and polymerizable composition including the same

ActiveCN102597037ASuppress cloudinessHigh transparencyOther chemical processesOptical elementsPhosphateAliphatic alcohol

Provided is a method for producing an internal mold release agent for an optical material comprising a step for heating, to within a range of 80 C to 140 C, a composition containing (a) a phosphate ester compound and (b) an alcohol compound formed from a C1-10 aliphatic alcohol and / or aromatic alcohol such that, when the total amount of (a) and (b) is 100 wt%, the alcohol compound (b) content is 2.5 wt% or higher.

Owner:MITSUI CHEM INC

Phase difference film, circular polarization plate and organic EL display manufactured using phase difference film

InactiveCN104769463AHigh phase difference displayImprove visibilityElectroluminescent light sourcesSolid-state devicesIn planePhase difference

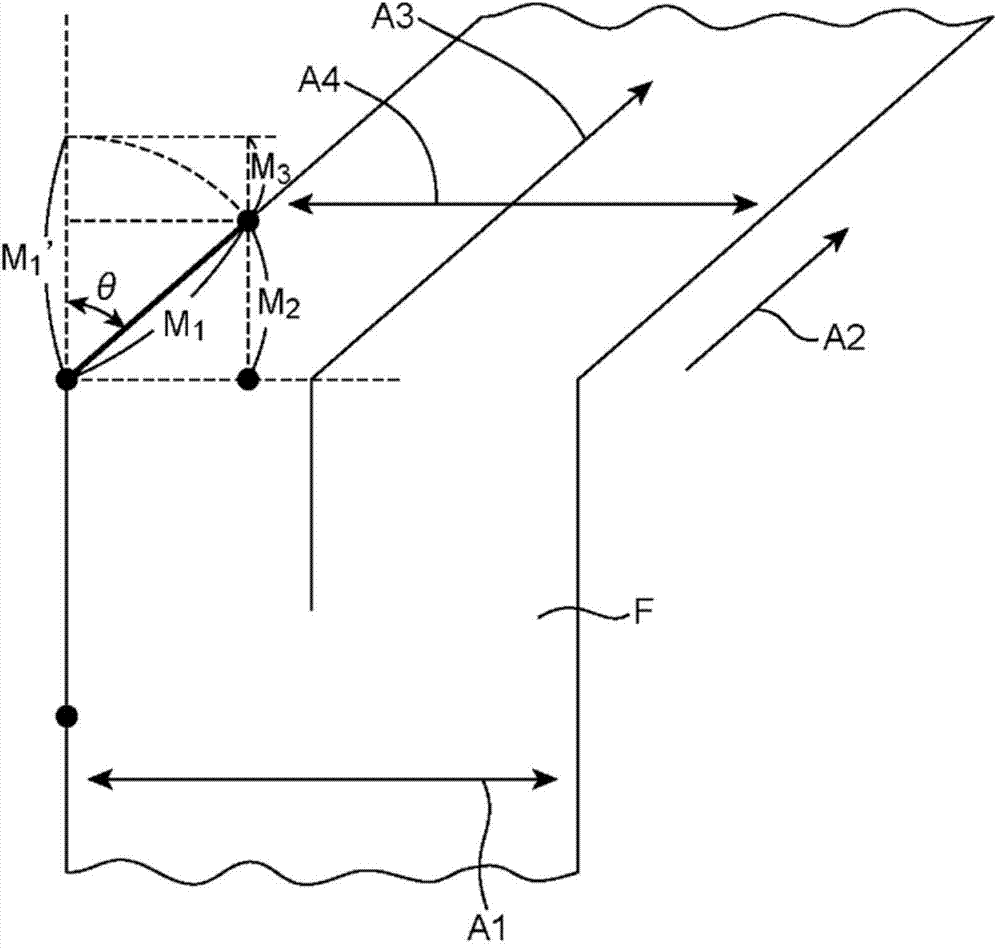

A phase difference film according to the present invention has an in-plane phase difference (Ro550) of 100 to 155nm in a wavelength of 550nm, and the ratio of an in-plane phase difference (Ro450) to Ro550 in a wavelength of 450nm is 0.72 to 0.95. The ratio of Ro550 to an in-plane phase difference (Ro650) in a wavelength of 650nm is 0.83 to 0.97. The phase difference film has a slow axis of 10° to 80° with reference to the longitudinal direction, and contains a resin having a positive intrinsic birefringence, an additive that functions to increase retardation and adjust wavelength dispersion, and an additive having a negative intrinsic birefringence.

Owner:KONICA MINOLTA INC

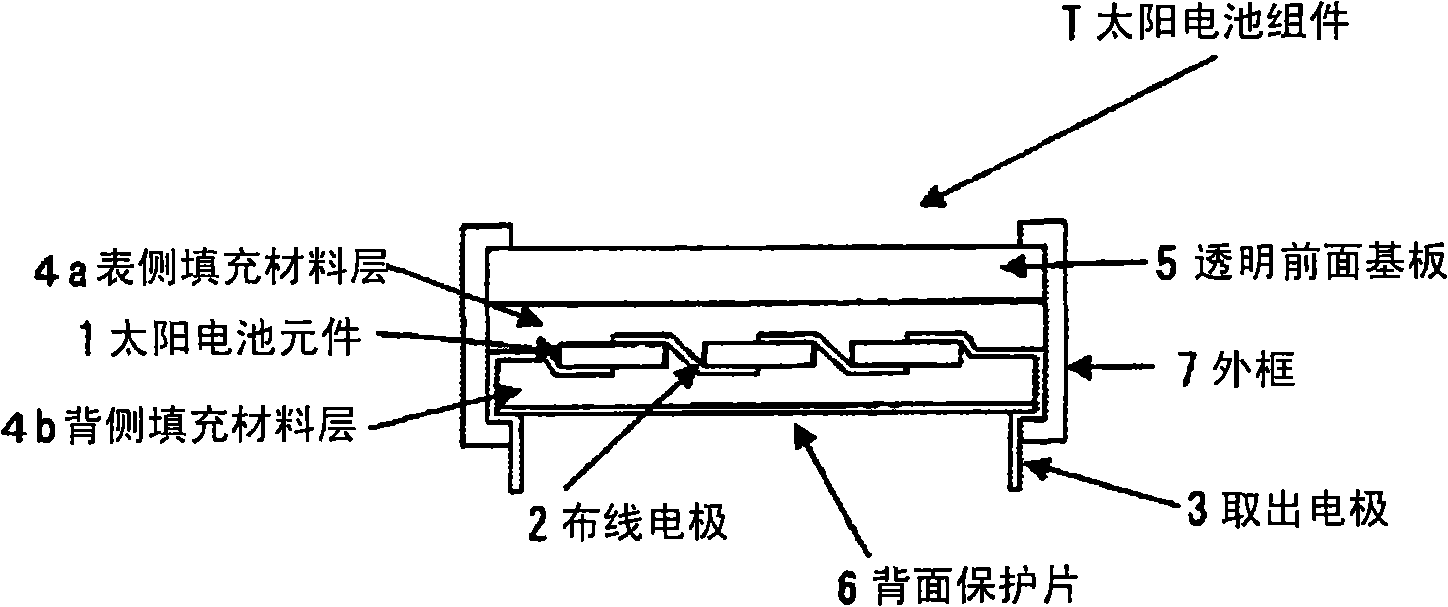

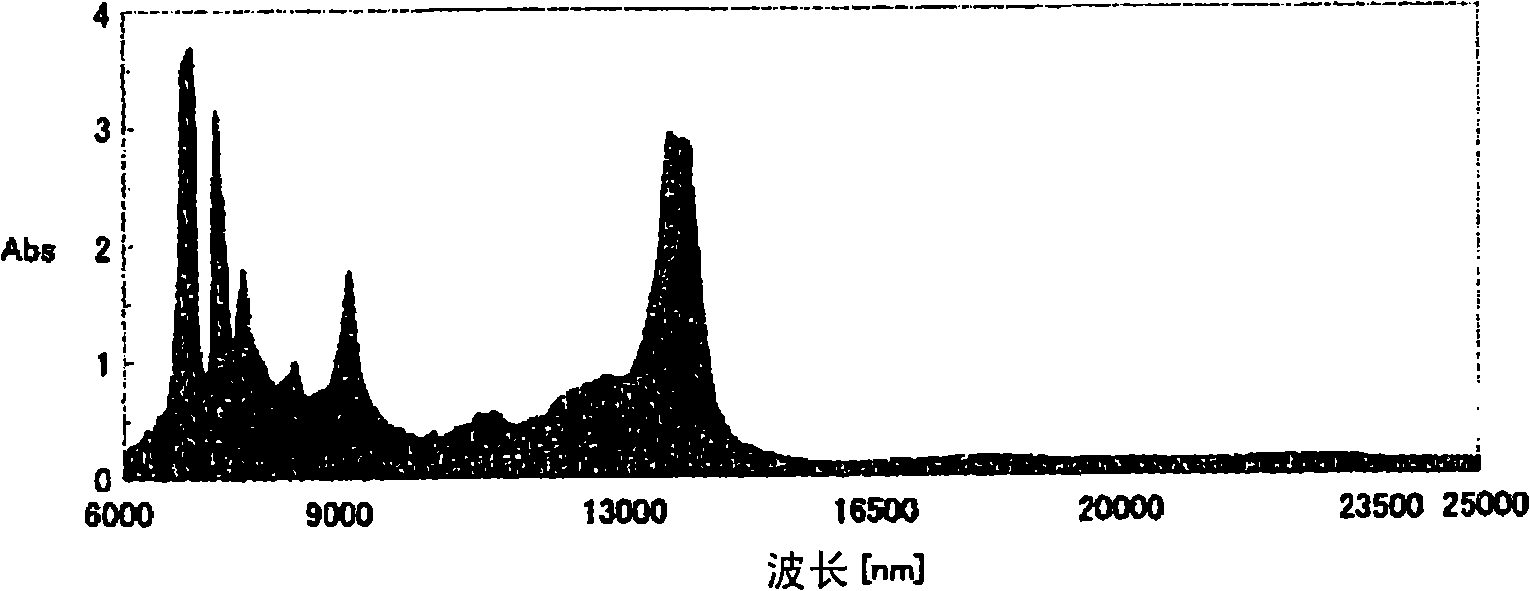

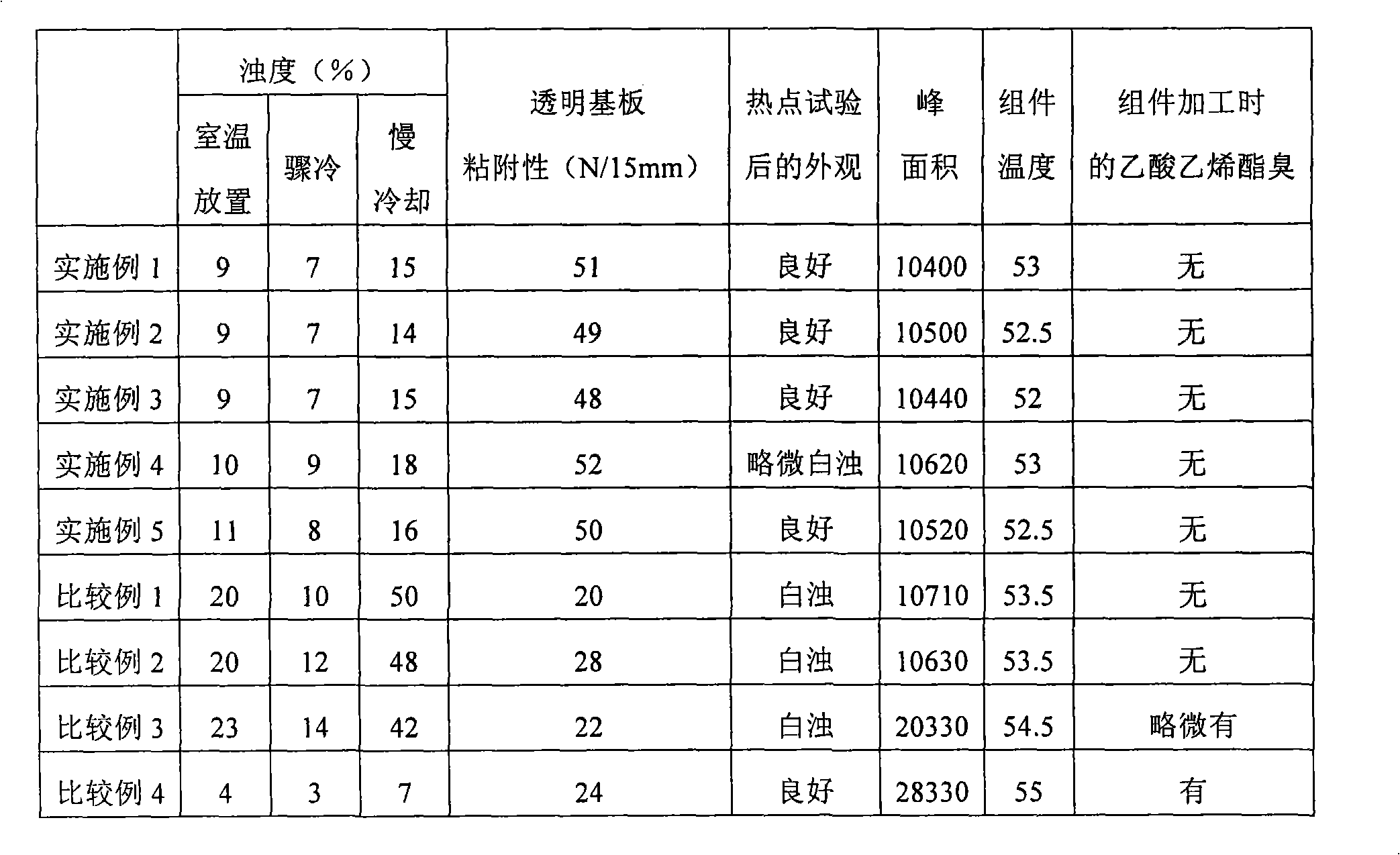

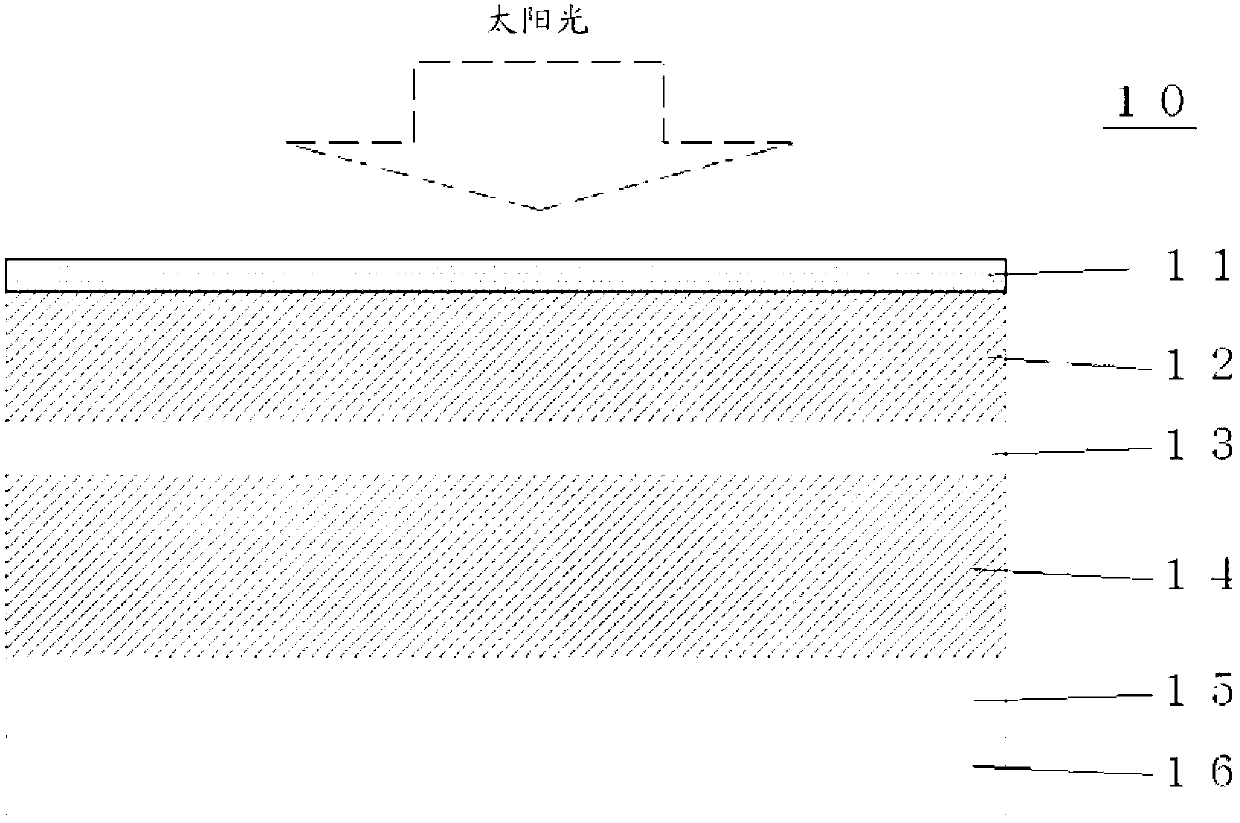

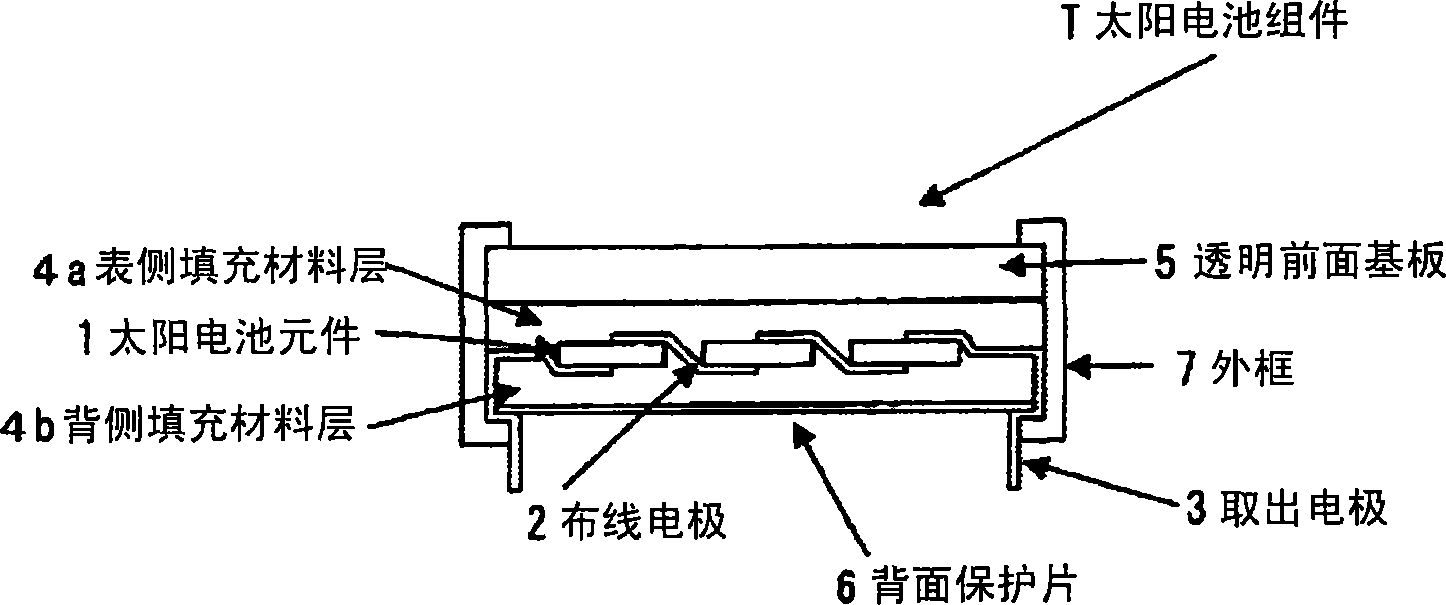

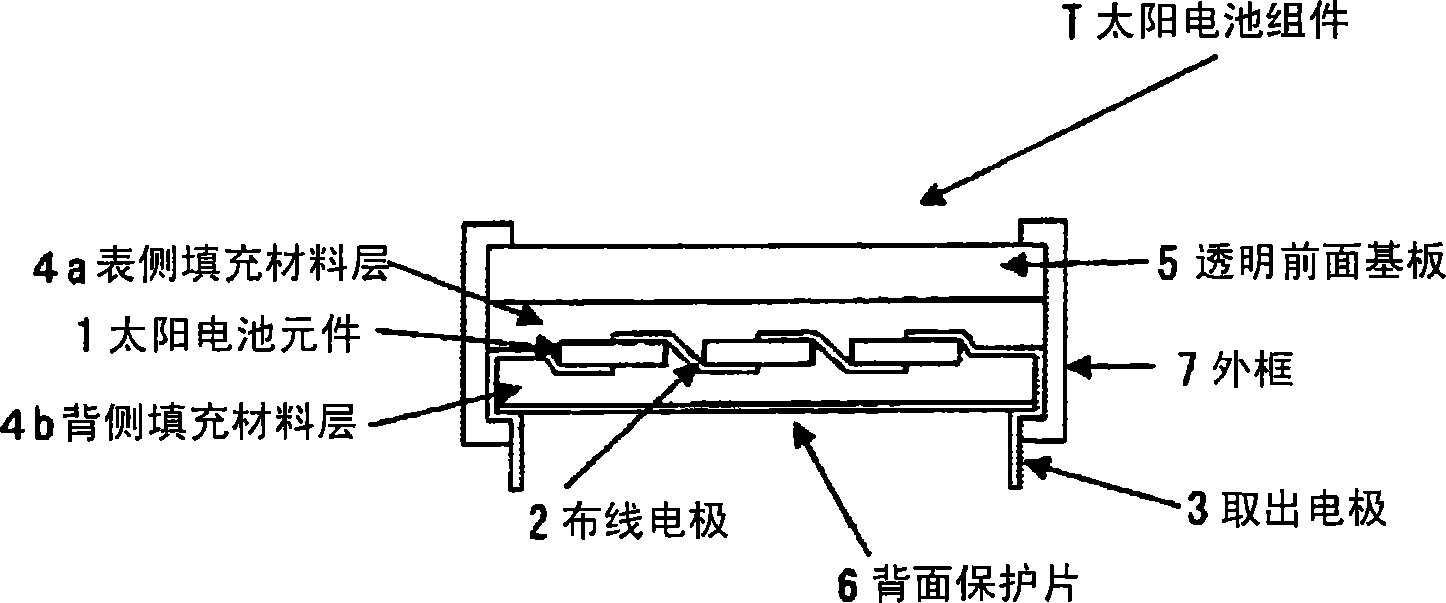

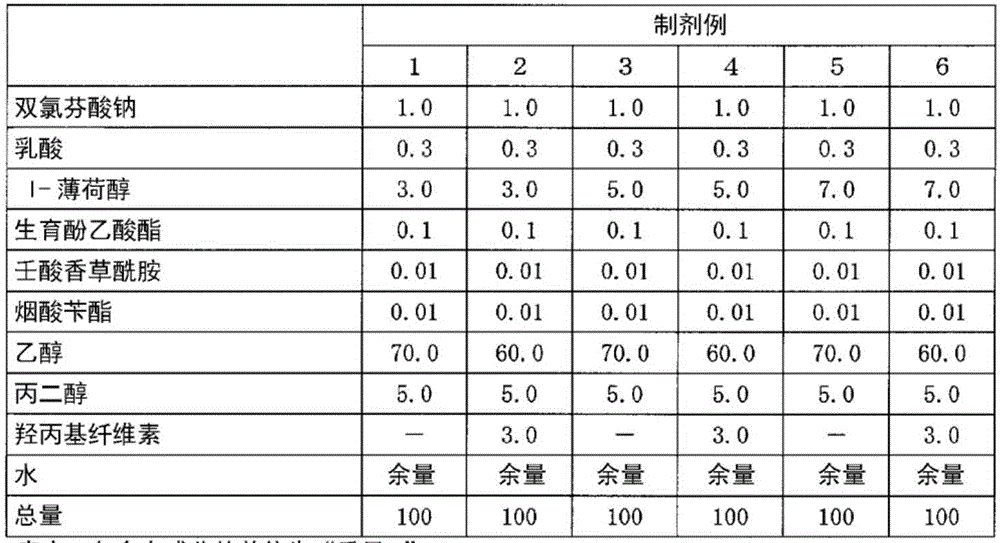

Filler for solar cell module, solar cell module using same, and method for producing filler for solar cell module

InactiveCN101317275ASuppress cloudinessChemical recyclingCoatingsLow-density polyethyleneLinear low-density polyethylene

Disclosed is a filler for solar cell modules which is suppressed in white turbidity in case where a hot spot phenomenon occurs. Specifically disclosed is a filler for solar cell modules comprising a filler resin containing a silane-modified resin obtained by polymerizing an ethylenically unsaturated silane compound and a polyethylene for polymerization, and a masterbatch containing an ultraviolet absorbent, a light stabilizer, a heat stabilizer and a polyethylene for masterbatch. This filler for solar cell modules is characterized in that the polyethylene for polymerization and the polyethylene for masterbatch are composed of a metallocene linear low-density polyethylene having a density within the range of 0.895-0.910 g / cm<3>.

Owner:DAI NIPPON PRINTING CO LTD +1

Polymerizable composition, transparent resin, optical material, plastic lens, and method for manufacturing transparent resin

ActiveCN107075065ASuppress cloudinessSuppresses Optical DistortionOptical articlesOptical partsThiolSulfur

Provided are: a polymerizable composition that can inhibit the occurrence of turbidity, optical distortion, and striae in a transparent resin obtained therefrom; the transparent resin obtained from the polymerizable composition; an optical material containing the transparent resin; a plastic lens containing the optical material; and a method for manufacturing the transparent resin. The polymerizable composition contains a polyiso(thio)cyanate compound and a polythiol compound that has at least three mercapto groups, wherein the polyiso(thio)cyanate compound consists of a polyiso(thio)cyanate compound containing no aromatic rings, and the polythiol compound has a thiol equivalence ratio, which is the ratio of the measured value of thiol equivalent to the theoretical value of thiol equivalent, of at least 0.900 but less than 1.000.

Owner:HOYA LENS THAILAND LTD

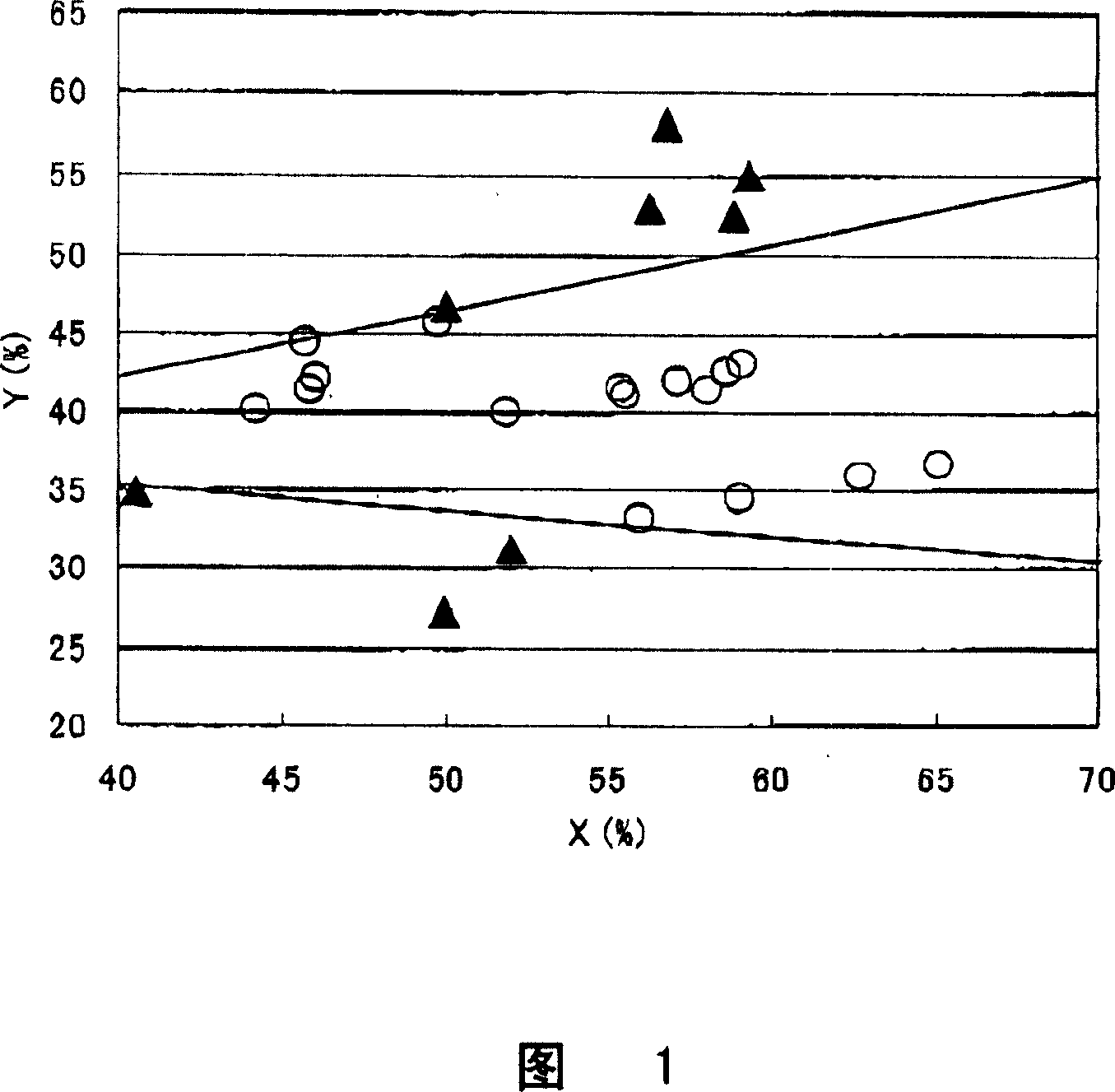

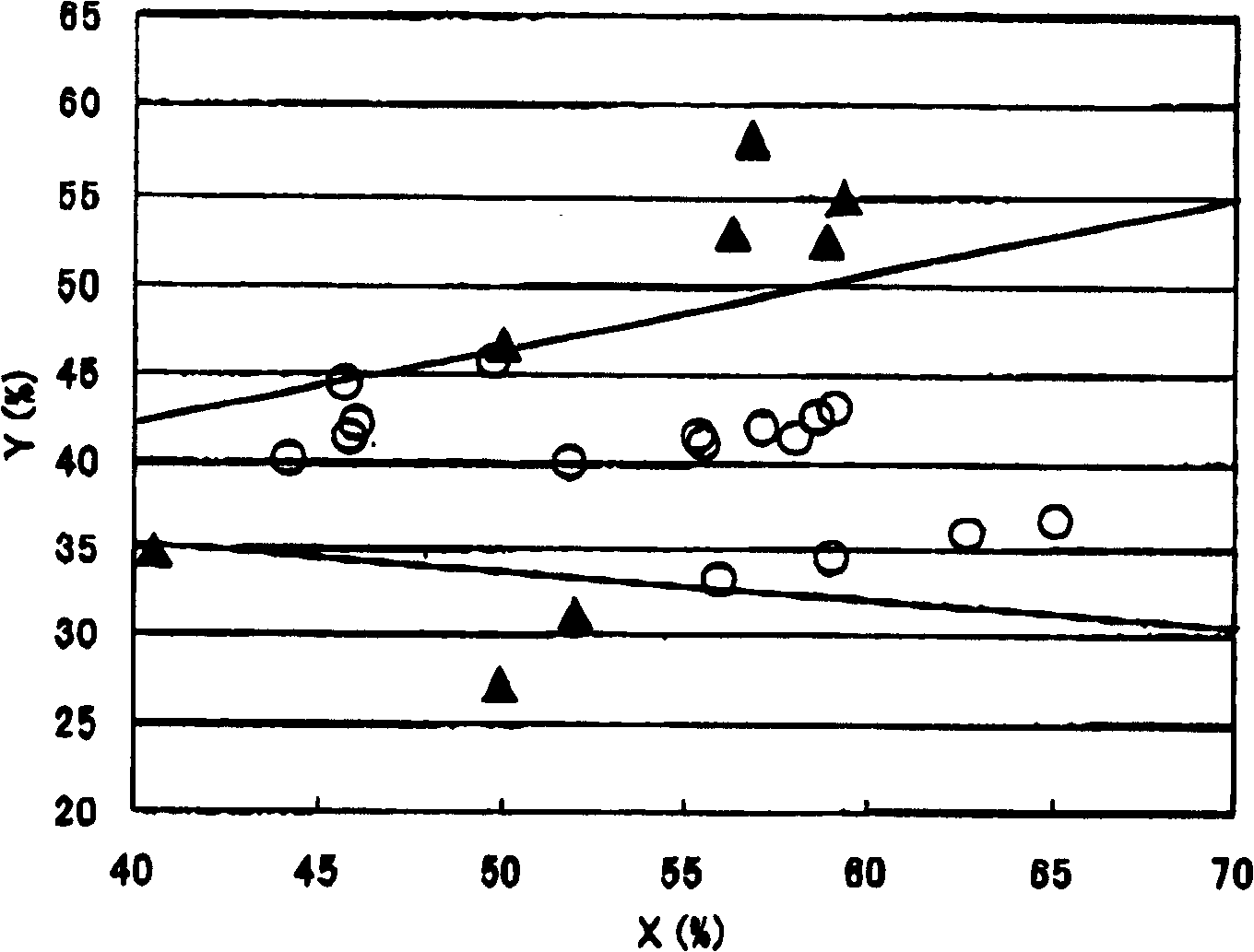

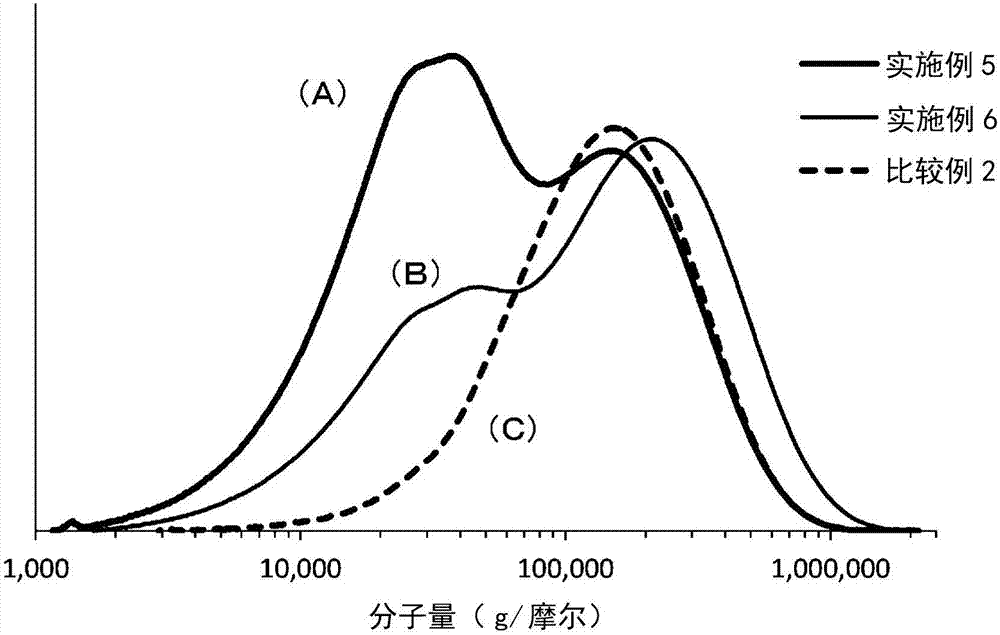

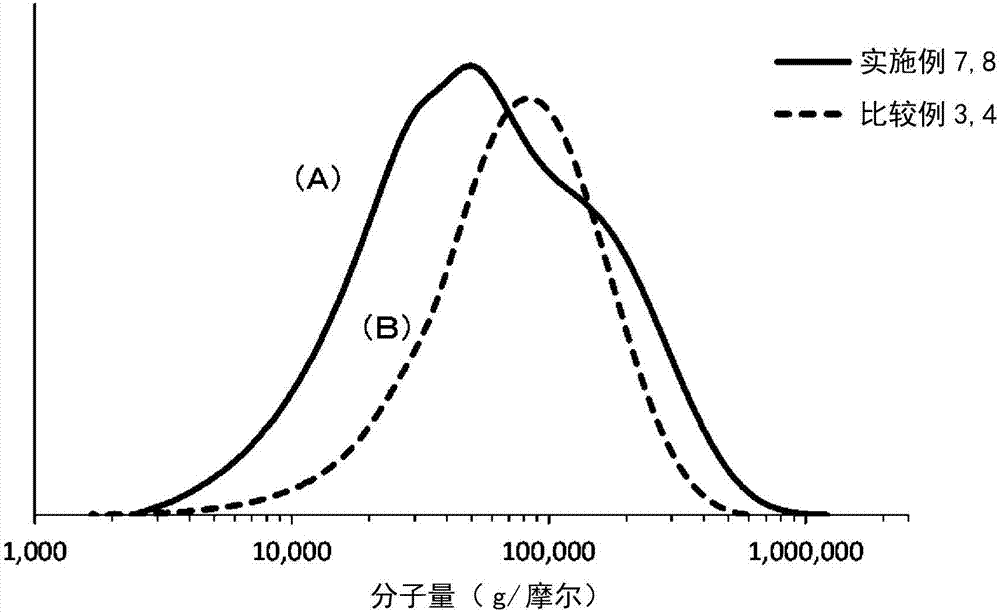

Adhesive

ActiveCN1958703AGood flexibilityCurb archingNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveAcrylic resin

Provided is an adhesive which does not generate appearance changes at optical laminated body and has excellent durability in the condition of high temperature and humidity and repeatedly heating and cooling containing acrylic resin (1) and (2), wherein the relationship between THF insoluble component X(%) of the adhesive and Y(%) represented by formula III satisfies formula I and II: 40 <= X <= 70 (I), -0.51X +41 < 0.45X + 24 (II), Y = B - (100 - X) * C / 100 (III), wherein B is a weight percentage of the component, which has a molecular weight of no less than 300000, of the mixture of (1) and (2), and C is a weight percentage of the component, which has a molecular weight of no less than 300000, of the THF insoluble component, and (1) is the acrylic resin having a weight-average molecular weight of from 50000 to 250000, (2) is the acrylic resin containing (b) having a weight-average molecular weight of from 1000000 to 1500000, and (b) is the monomer with polar functional groups and alkene double bond.

Owner:SUMITOMO CHEM CO LTD

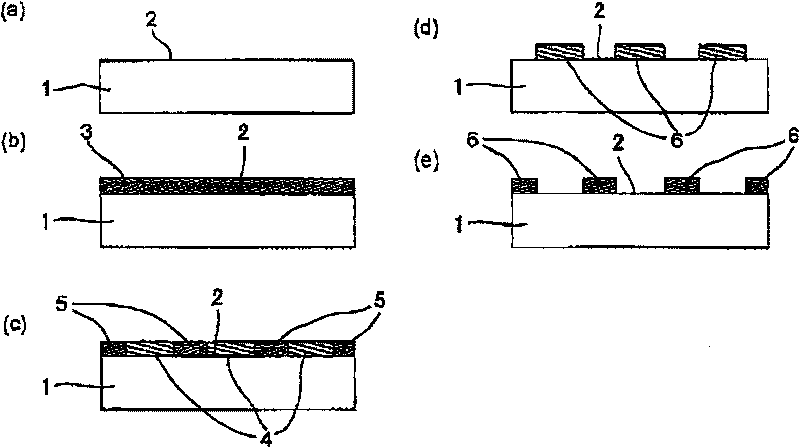

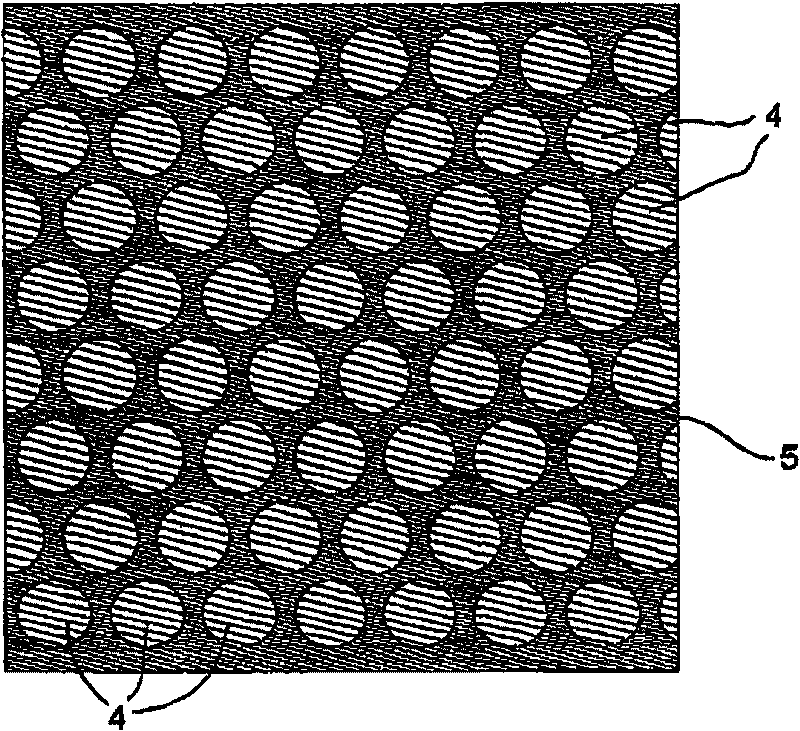

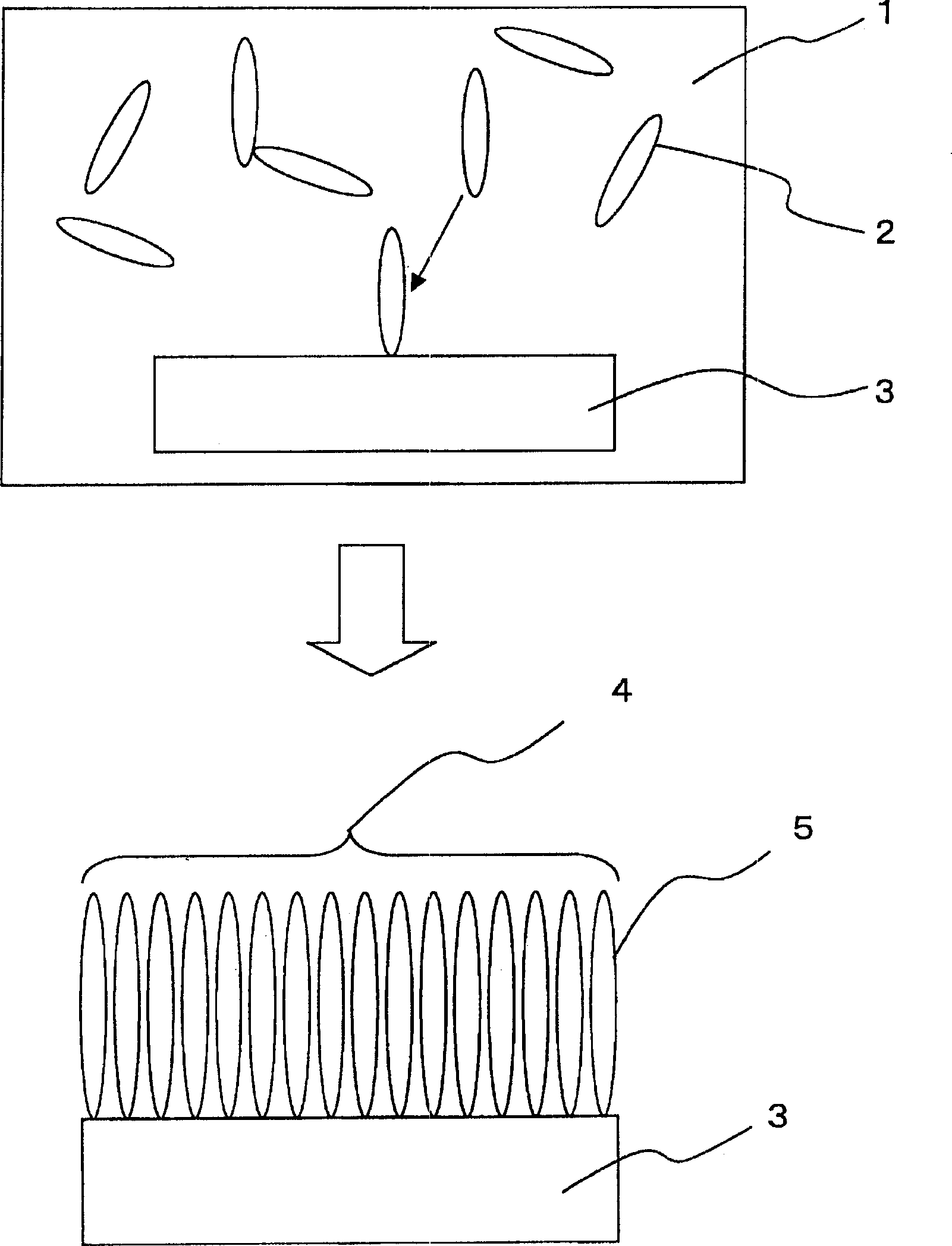

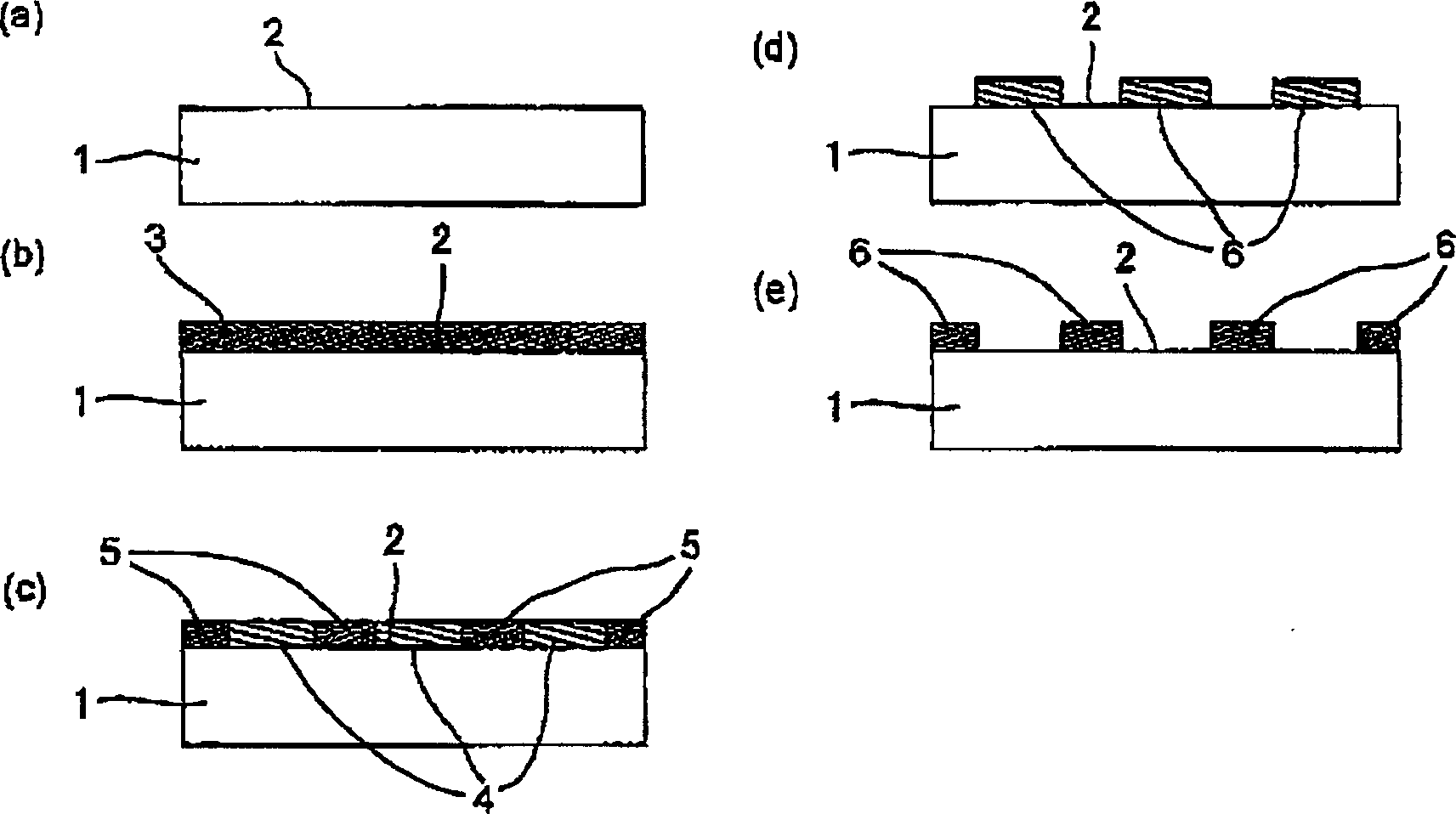

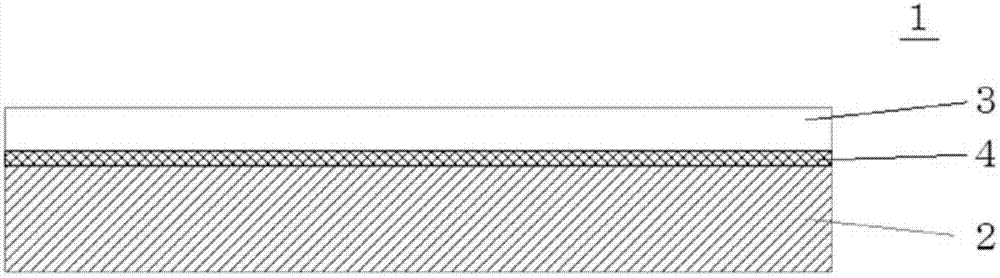

A method for manufacturing mold and a method for manufacturing anti-dazzle membrane

ActiveCN101712202AHigh anti-glare functionReduce contrastPhotomechanical apparatusOptical articlesCoated surfaceCopper plating

The invention relates to a method for manufacturing mold and a method for manufacturing anti-dazzle membrane. The method for manufacturing mold in the invention comprises the following procedures: a procedure of implementing copper or nickel plating on surface of base material for a mold; a procedure of grinding the plated surface; a procedure of performing filming by coating light-sensitive polymer; a procedure of exposing pattern on the light-sensitive polymer membrane; a procedure of developing the light-sensitive polymer membrane; a procedure of implementing etching treatment by taking the developed light-sensitive polymer membrane as mask, and forming concavo convex on grinded coated surface; a procedure of implementing chrome plating of the formed concavo convex surface; and in the procedure of etching treatment, whole surface of the base material for the mold is implemented etching treatment. The method for manufacturing anti-dazzle membrane in the invention used this mold.

Owner:SUMITOMO CHEM CO LTD

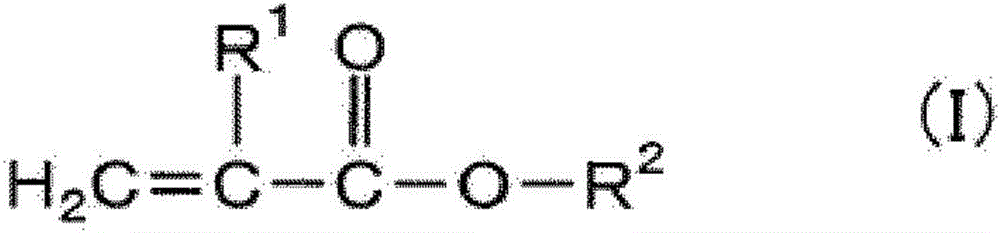

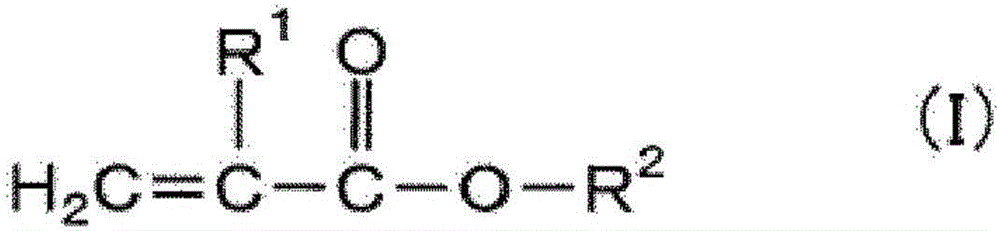

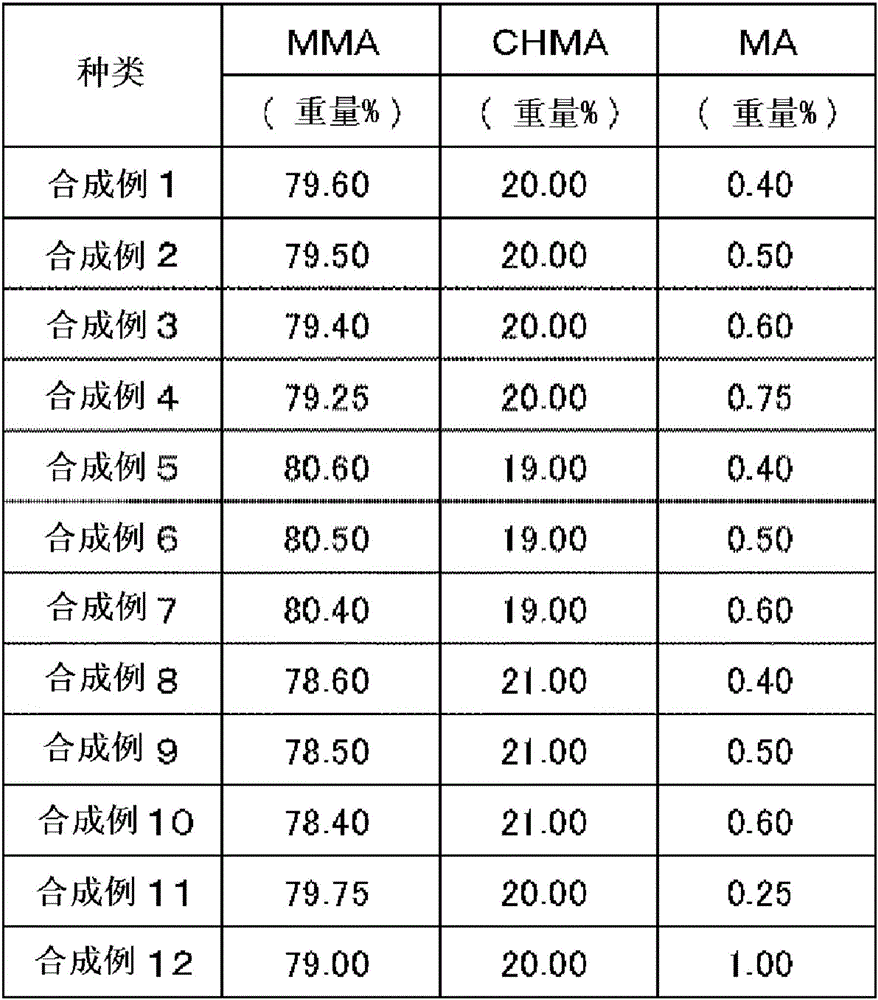

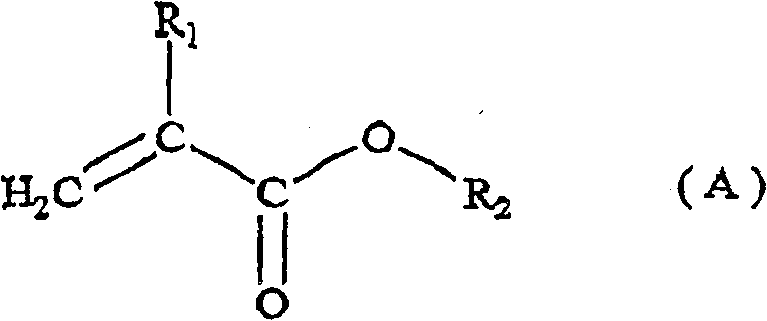

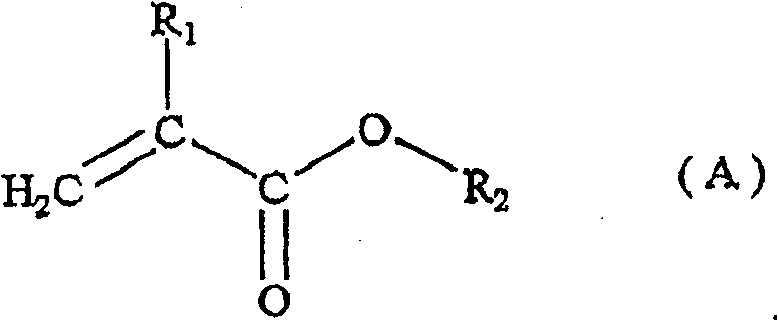

Resin composition and molded article thereof

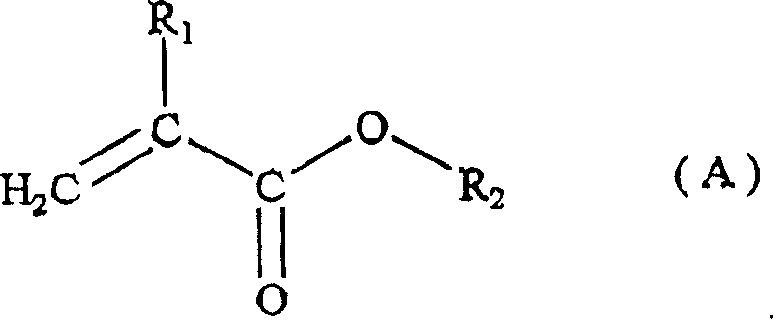

InactiveCN105980473AHigh transparencySuppress cloudinessPolarising elementsOptical articlesMeth-Polycarbonate

Provided are a resin composition that makes it less likely that a molded article obtained therefrom will become cloudy even if the heating temperature in the molding process is a higher temperature, a resin film obtained by molding same, and a stretched film obtained by stretching the resin film. A resin composition containing a methacrylic resin and an aromatic polycarbonate resin, wherein: the methacrylic resin is obtained by polymerizing a monomer component containing 59-90 wt% of methyl methacrylate, 10-40 wt% of a (meth)acrylic acid ester shown by formula (I), and 0.4-0.8 wt% of alkyl acrylate relative to a total of 100 wt% of monomer components; the weight-average molecular weight of the aromatic polycarbonate resin is 20,000-40,000; and the methacrylic resin and aromatic polycarbonate resin content is 50-95 parts by weight of methacrylic resin and 5-50 parts by weight of aromatic polycarbonate resin relative to a total of 100 parts by weight of methacrylic resin and aromatic polycarbonate resin.

Owner:SUMITOMO CHEM CO LTD

Method for manufacturing organic el display and organic el display

ActiveUS20130320840A1Avoid accumulationSuppress cloudinessDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOrganic layer

Owner:JOLED INC

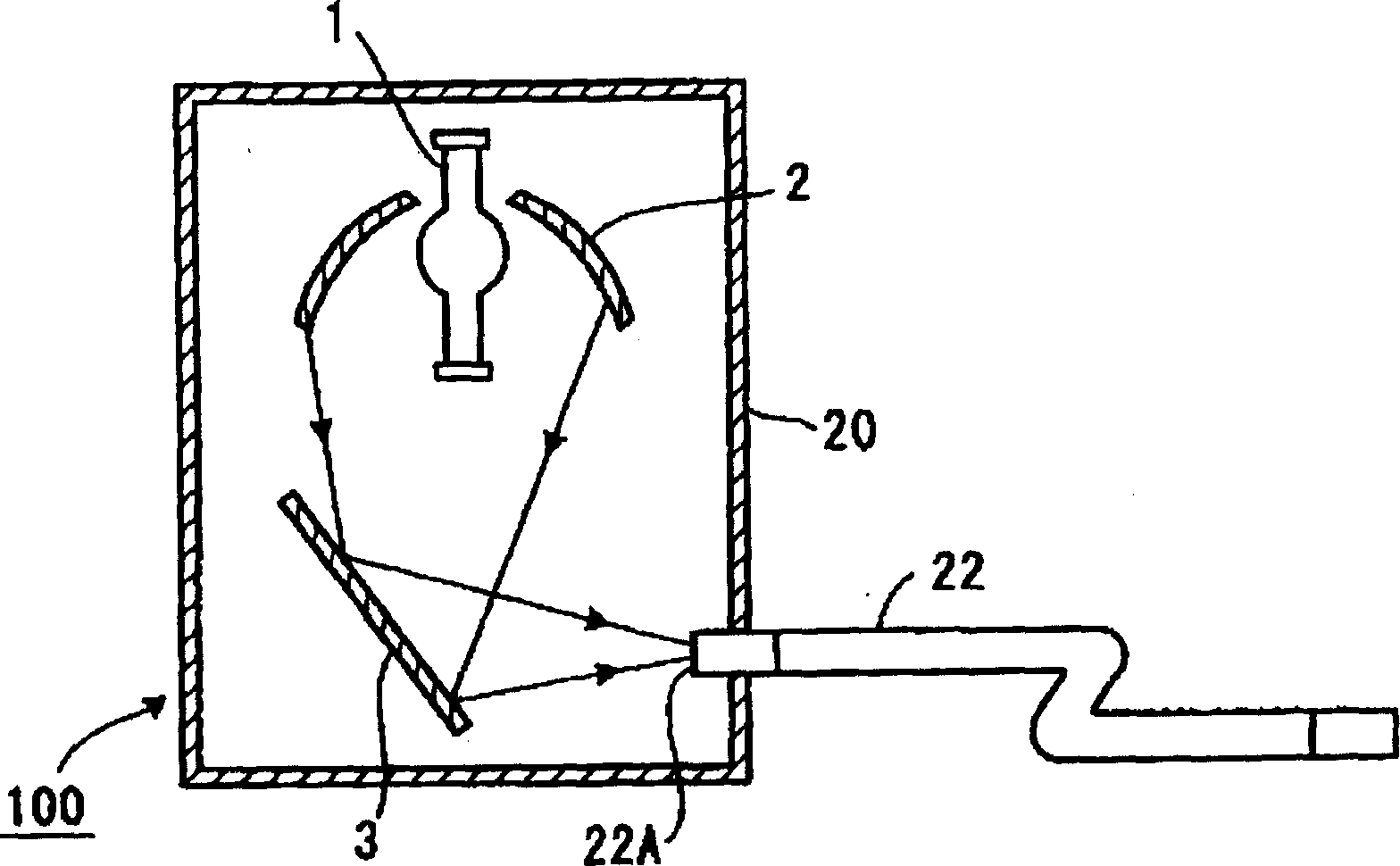

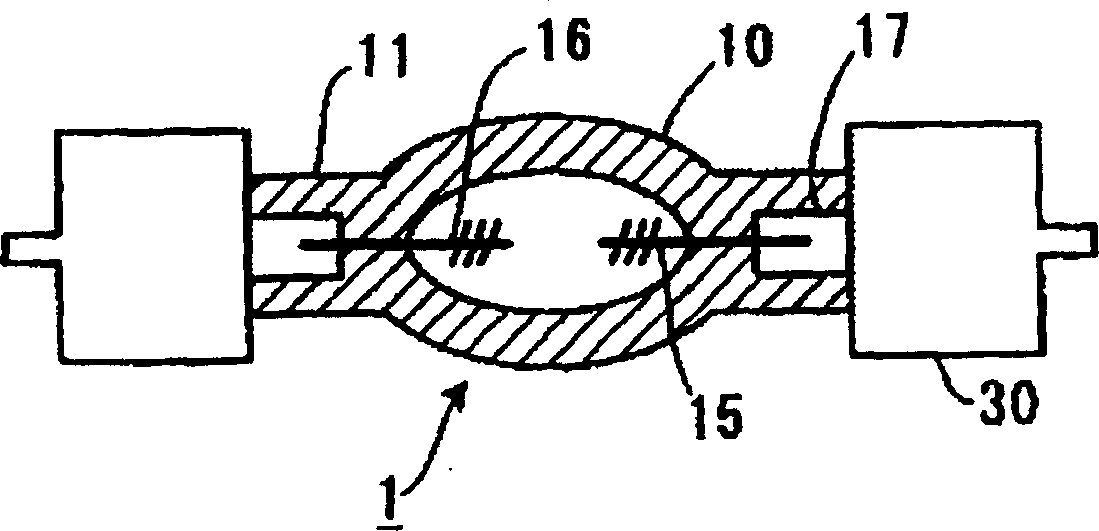

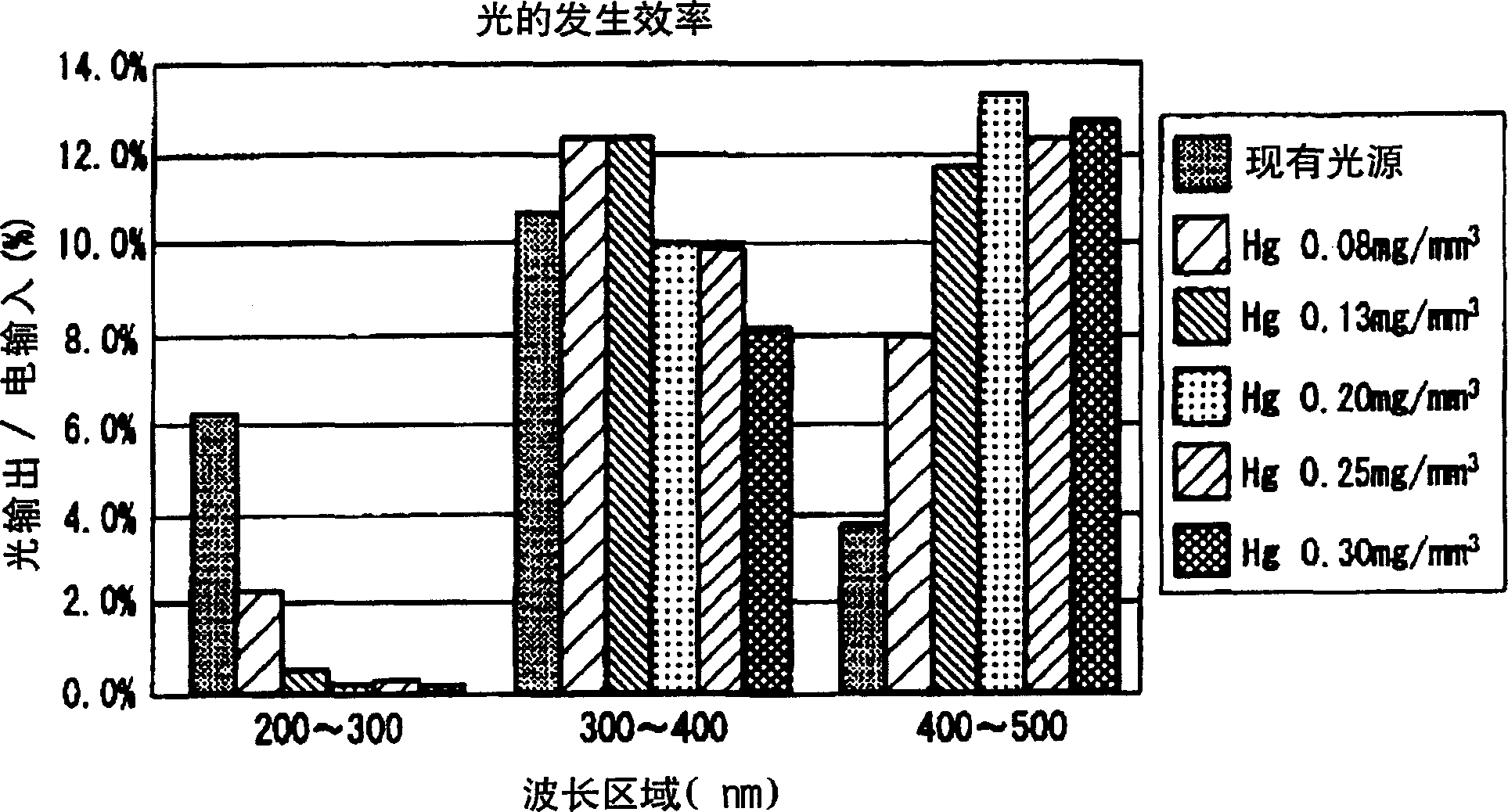

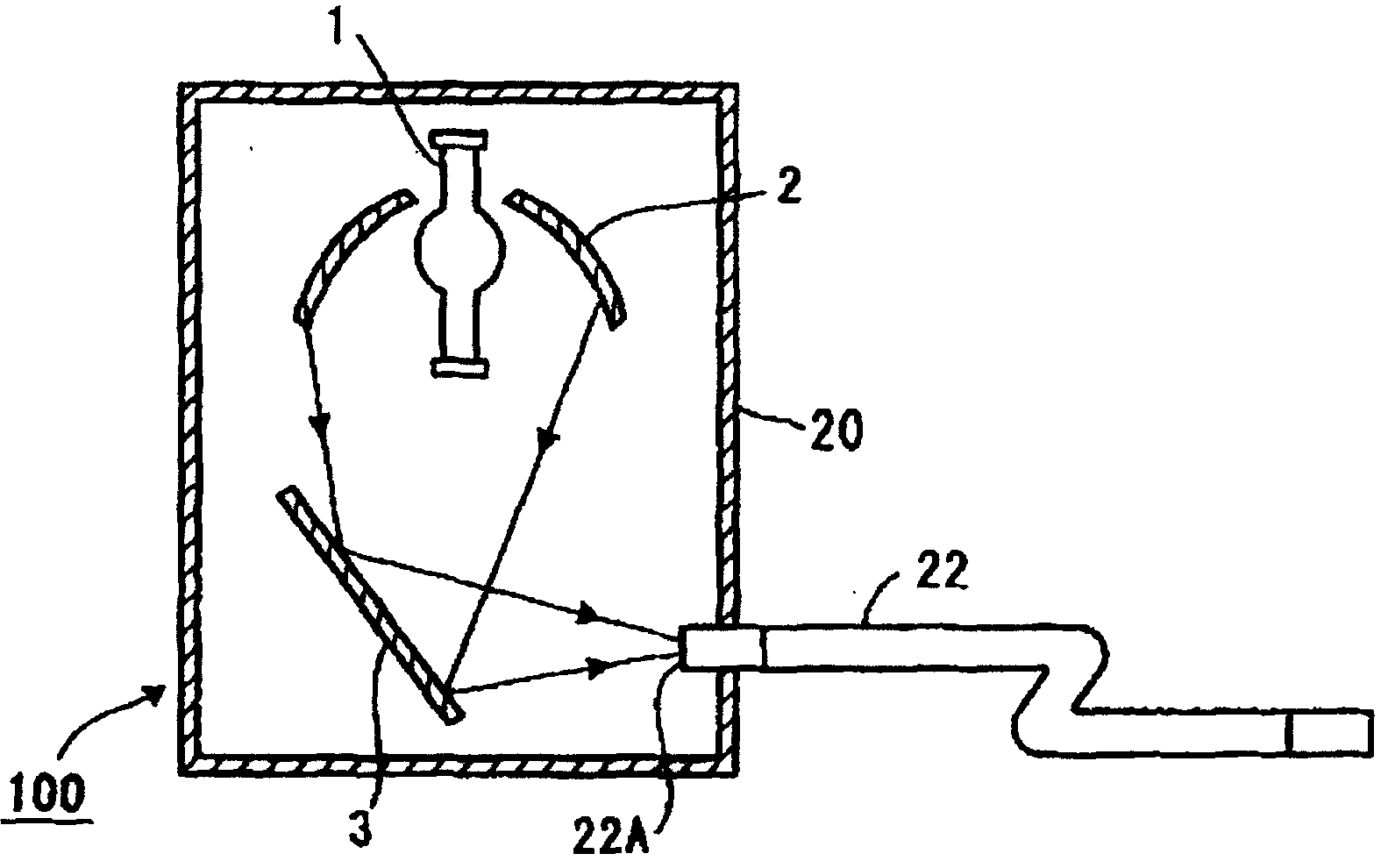

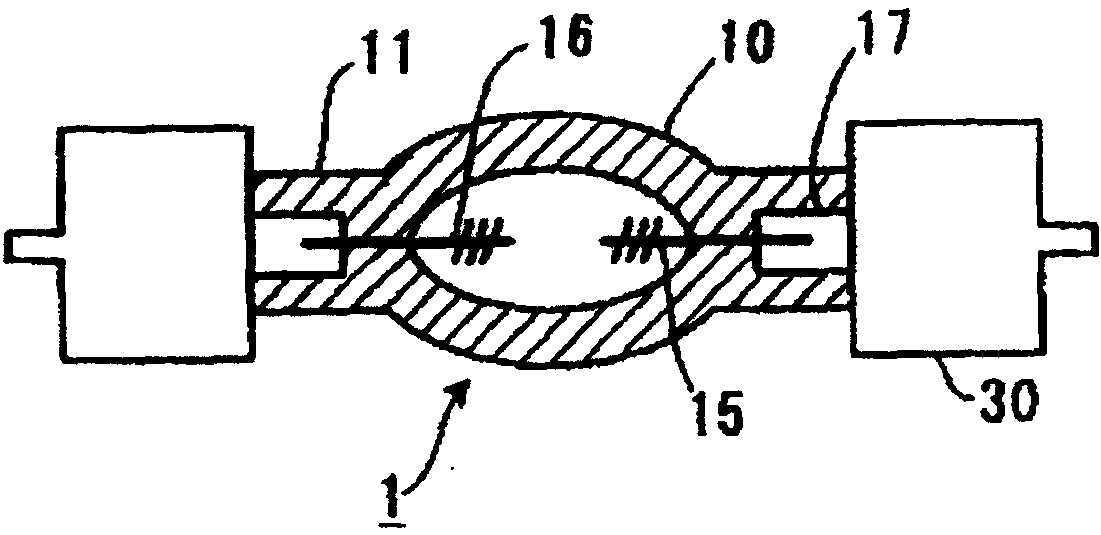

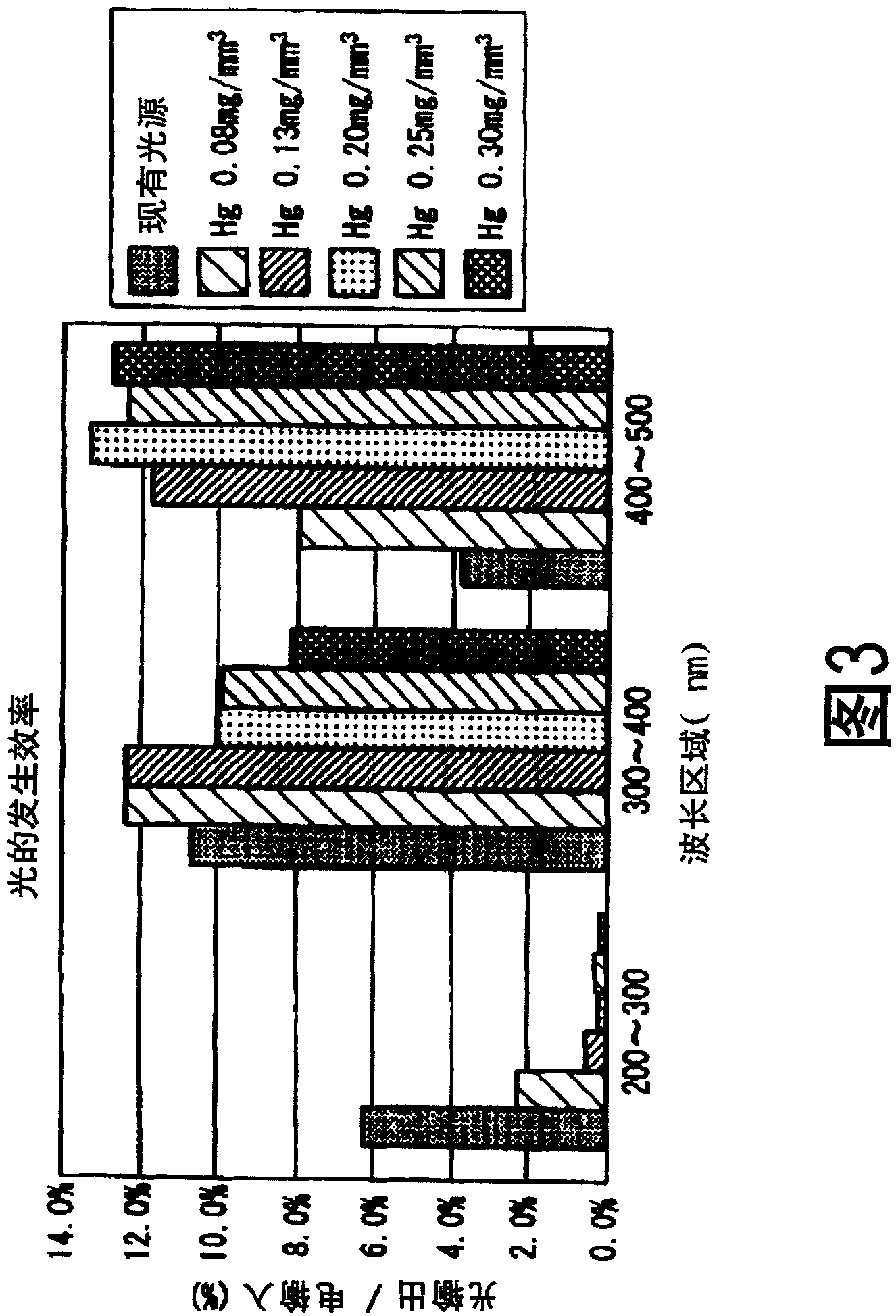

Uv light irradiating device

ActiveCN1725432AEfficient irradiationImprove light gathering efficiencyMechanical apparatusHandkerchiefsFiberNoble gas

The present invention relates to an ultraviolet irradiation device that is capable of highly efficiently converging UV light of 300nm to 400nm, which is suitable for solidification by ultraviolet, on a light incident opening of tiny fiber with a diameter of less than 5mm; a blocking light filter that blocks ultraviolet with the harmful wavelength of less than 300nm is not used; and the ultraviolet of 300nm to 400nm can be effectively radiated on an object. The present invention is characterized in that the device is provided with a high-pressure fluorescent mercury lamp with a pair of tungsten electrodes that are arranged in a discharging container that is formed by quartz glass; mercury of 0.08 to 0.30mg / mm<3>, rare gas and halogen are enclosed in the container; the distance between electrodes is 0.5 to 1.8 mm, which can highly efficiently irradiate the ultraviolet of 300 to 400nm; a light-converging component can converge the light from the high-pressure fluorescent mercury lamp and converge the ultraviolet of 300 to 400nm in an area with a diameter of less than Phi 5mm so as to radiate the irradiated object.

Owner:USHIO DENKI KK

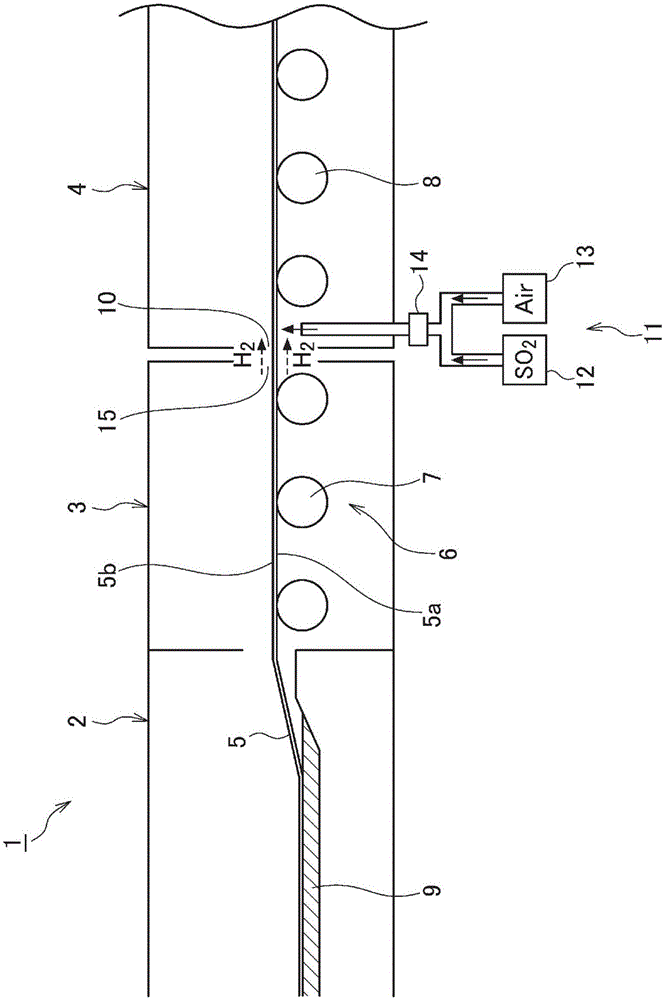

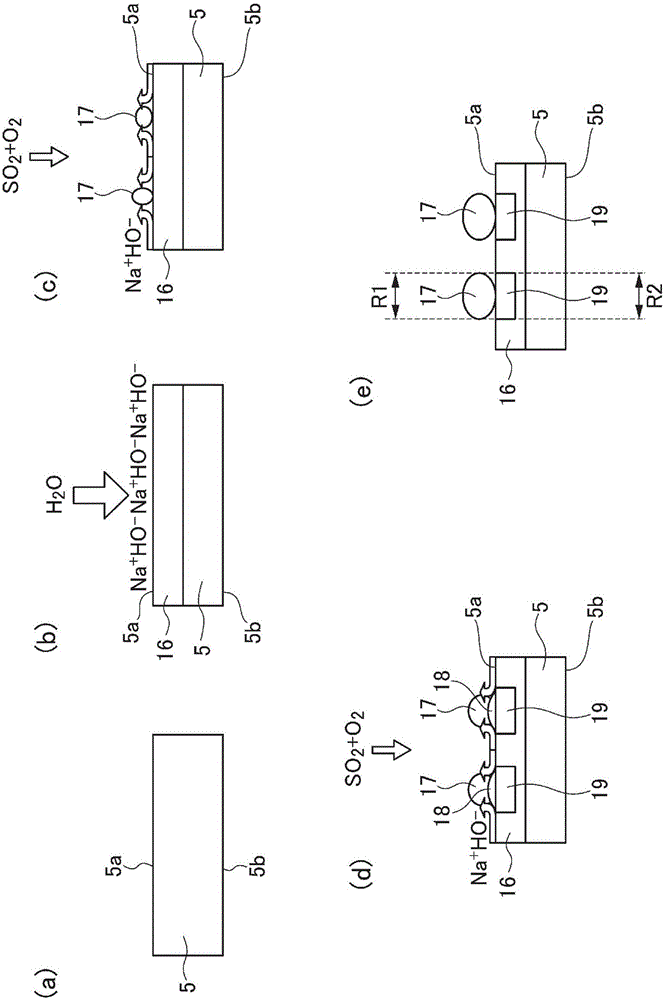

Glass plate and method for manufacturing same

InactiveCN106573830ADifficult to scatterSuppress cloudinessCoatingsInput/output processes for data processingSulfateGlass sheet

This glass plate has on the bottom surface thereof a buffer layer formed of a plurality of sulfate crystals, such bottom surface making contact with molten metal when carrying out formation by the float method. The median value of the circle equivalent diameters of the plurality of sulfate crystals, as seen from the thickness direction, is 350nm or less.

Owner:ASAHI GLASS CO LTD

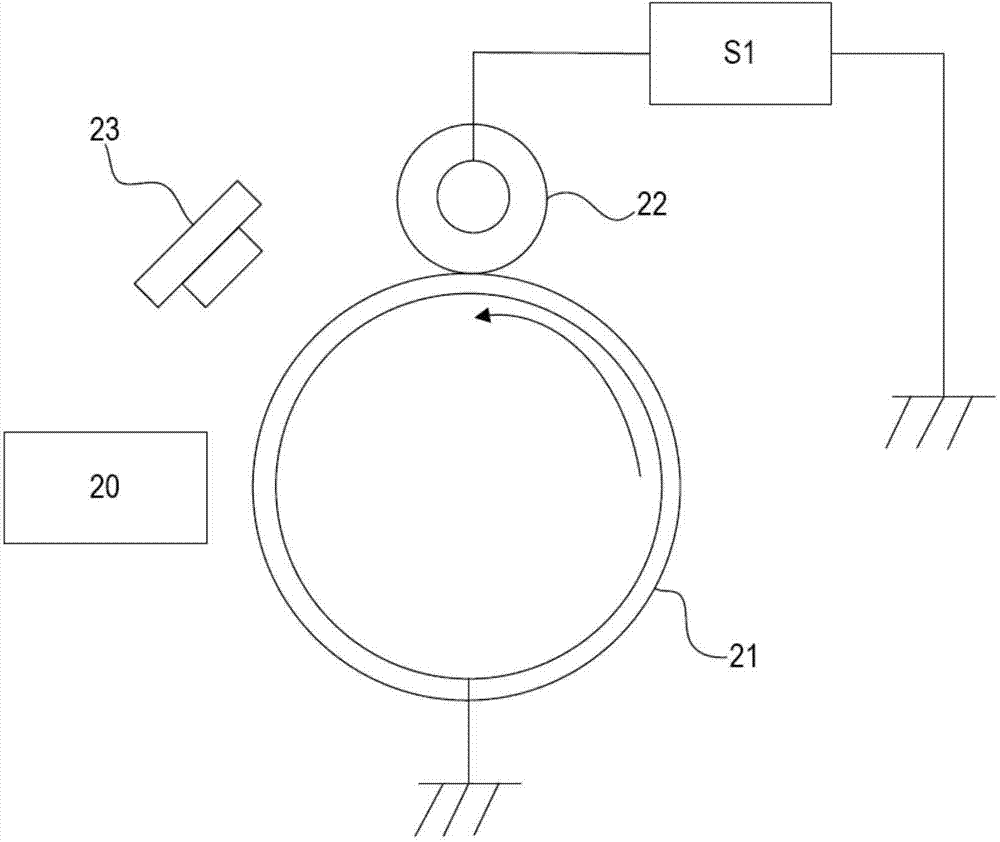

Method for manufacturing electrophotography member, and coating liquid

ActiveCN104204961ASuppress cloudinessPrevent precipitationShaft and bearingsElectrographic process apparatusSilane compoundsSurface layer

Provided is a method of producing a member for electrophotography capable of providing a high-quality electrophotographic image. The method of producing a member for electrophotography is a method of producing a member for electrophotography having an electro-conductive support, an elastic layer, and a surface layer, the method comprising: a first step of forming, on a surface of the elastic layer, a coat of a surface-layer coating liquid containing a hydrolyzed condensate of a hydrolyzable silane compound and a chelate titanium compound represented by the following general formula (2); and a second step of crosslinking the hydrolyzed condensate in the coat through cleavage of an epoxy group in the hydrolyzed condensate to form the surface layer:

Owner:CANON KK

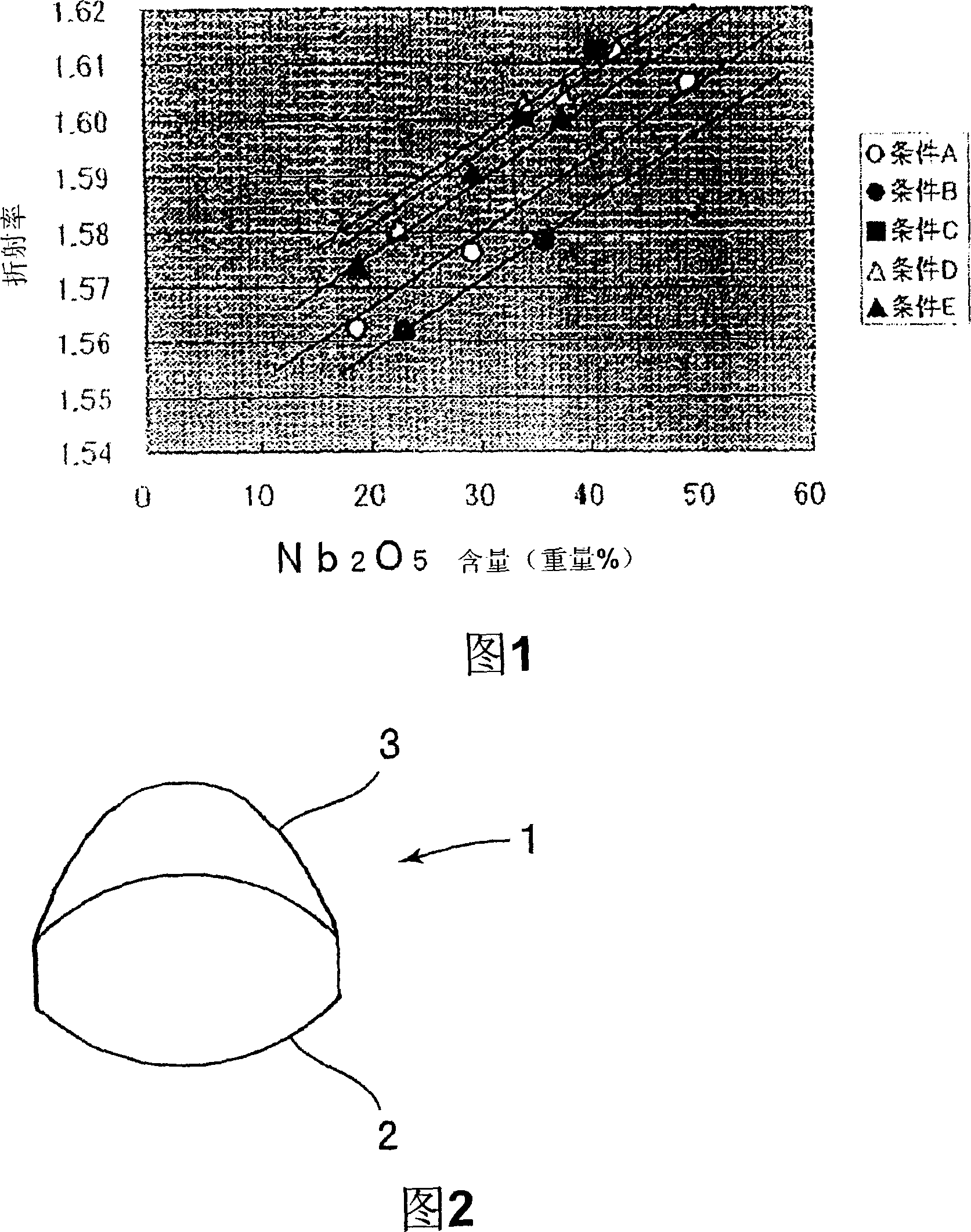

Organic-inorganic composite forming material, organic-inorganic composite, production method thereof and optical element

InactiveCN1986642APrevent agglutinationSuppress cloudinessOptical elementsOligomerInorganic particle

An organic-inorganic composite forming material which contains an organometallic polymer having an -M-O-M- bond (M denotes a metal atom), an acrylic monomer or oligomer having a hydrophilic group and inorganic particles. Preferably, the organometallic polymer has Si in the place of M and is obtained via hydrolysis and polycondensation of trialkoxysilane having a photo- or thermally-polymerizable group and dialkoxysilane having a phenyl group.

Owner:SANYO ELECTRIC CO LTD

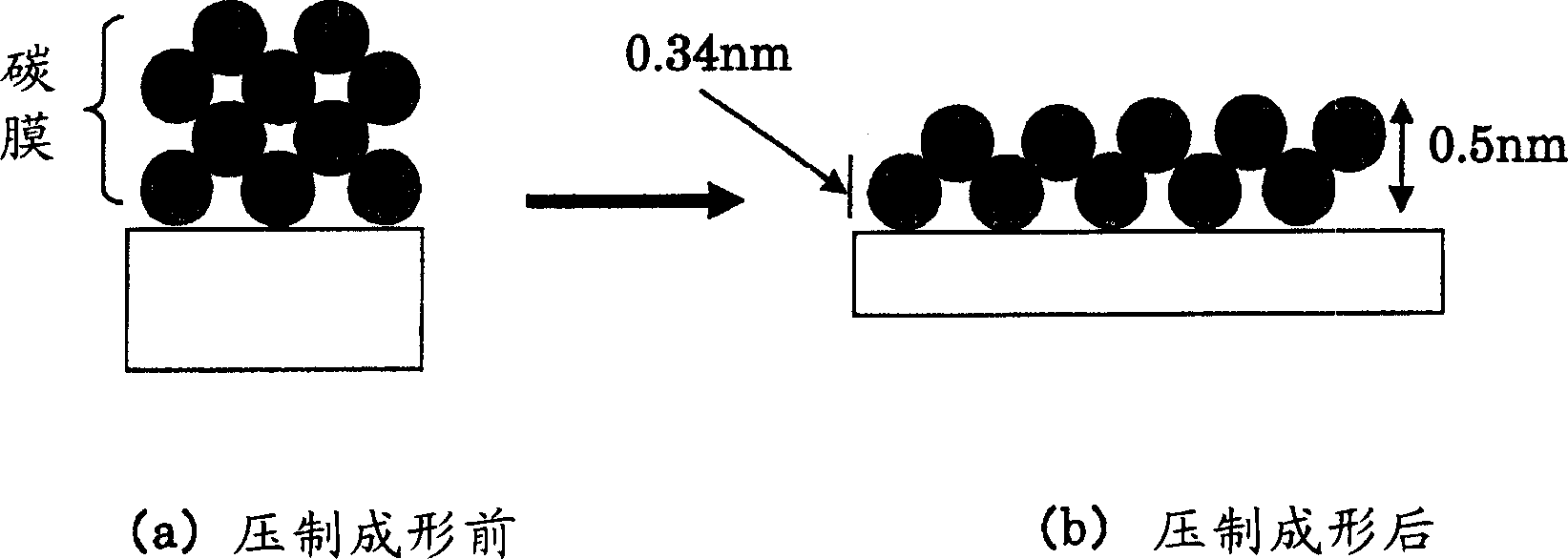

Method of manufacturing glass optical device

InactiveCN1552649AAvoid WeldingPrevent perforation caused byMaterial nanotechnologyVacuum evaporation coatingCarbon filmOptical glass

A method of manufacturing optical glass elements comprising the step of press molding a preformed glass material while in a heat-softened state, which material having a carbon film on a surface thereof, to transfer a molding surface of a pressing mold. The carbon film is less than or equal to 10 nm in thickness and is formed in such a manner that after press molding, a carbon film comprising at least two carbon atom layers in thickness is present on the surface of the optical glass element that has been molded by the molding surface. In the method of manufacturing glass elements, fusion between the glass material and the molding surfaces, flaws, and breach are prevented and fogging does not occur on the surface of the optical element obtained.

Owner:HOYA CORP

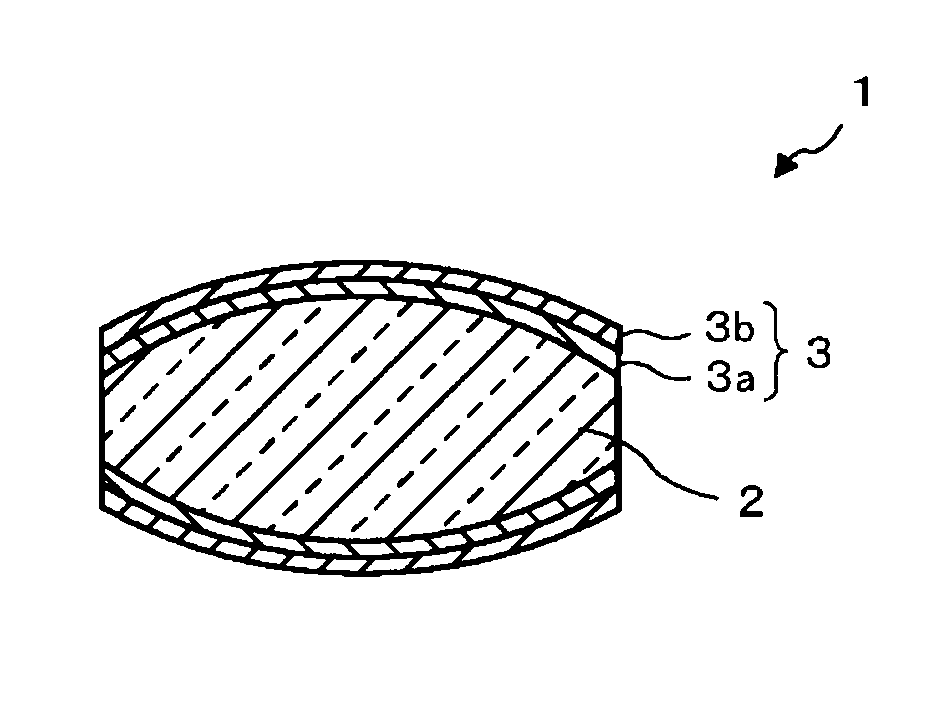

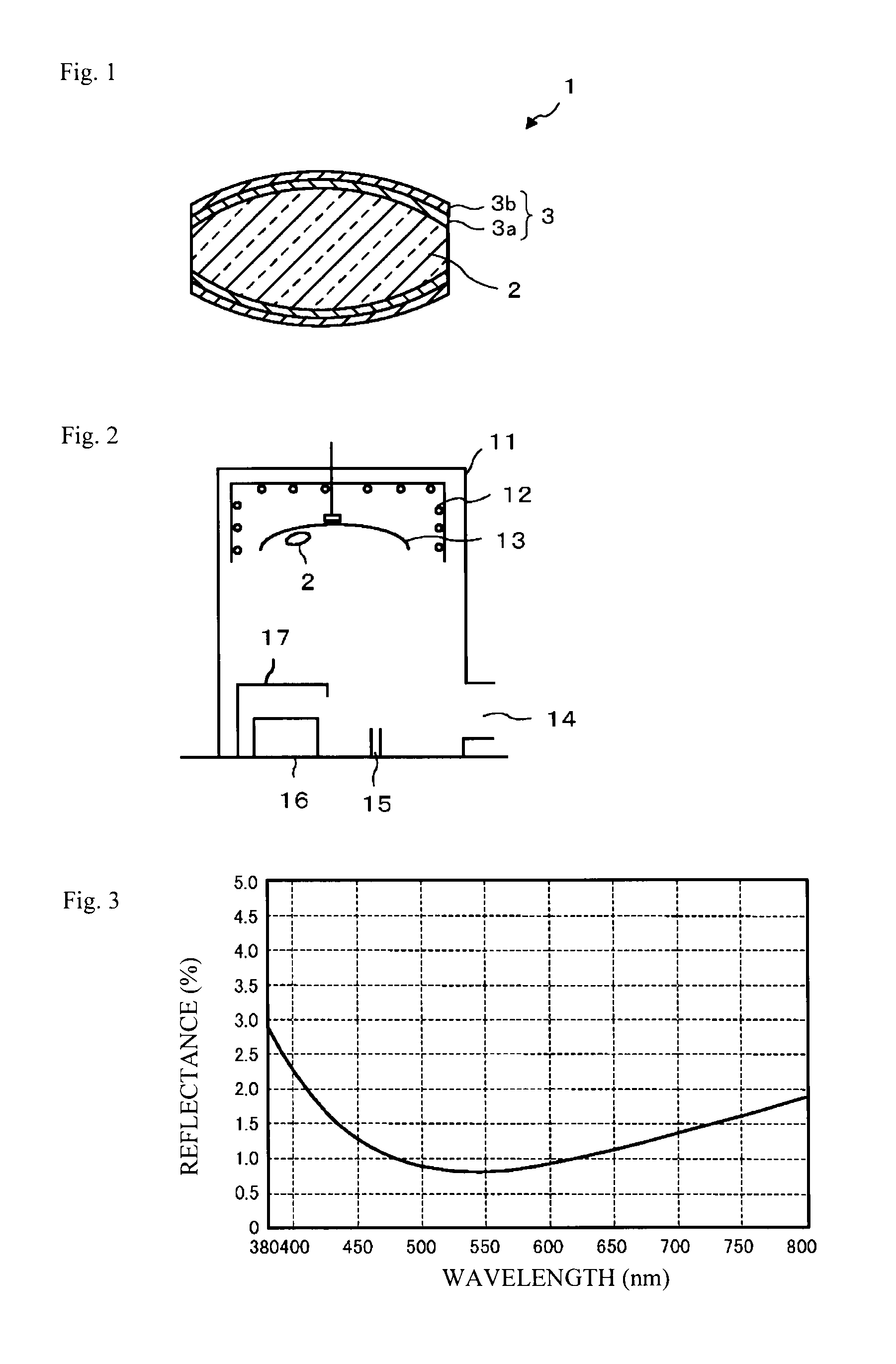

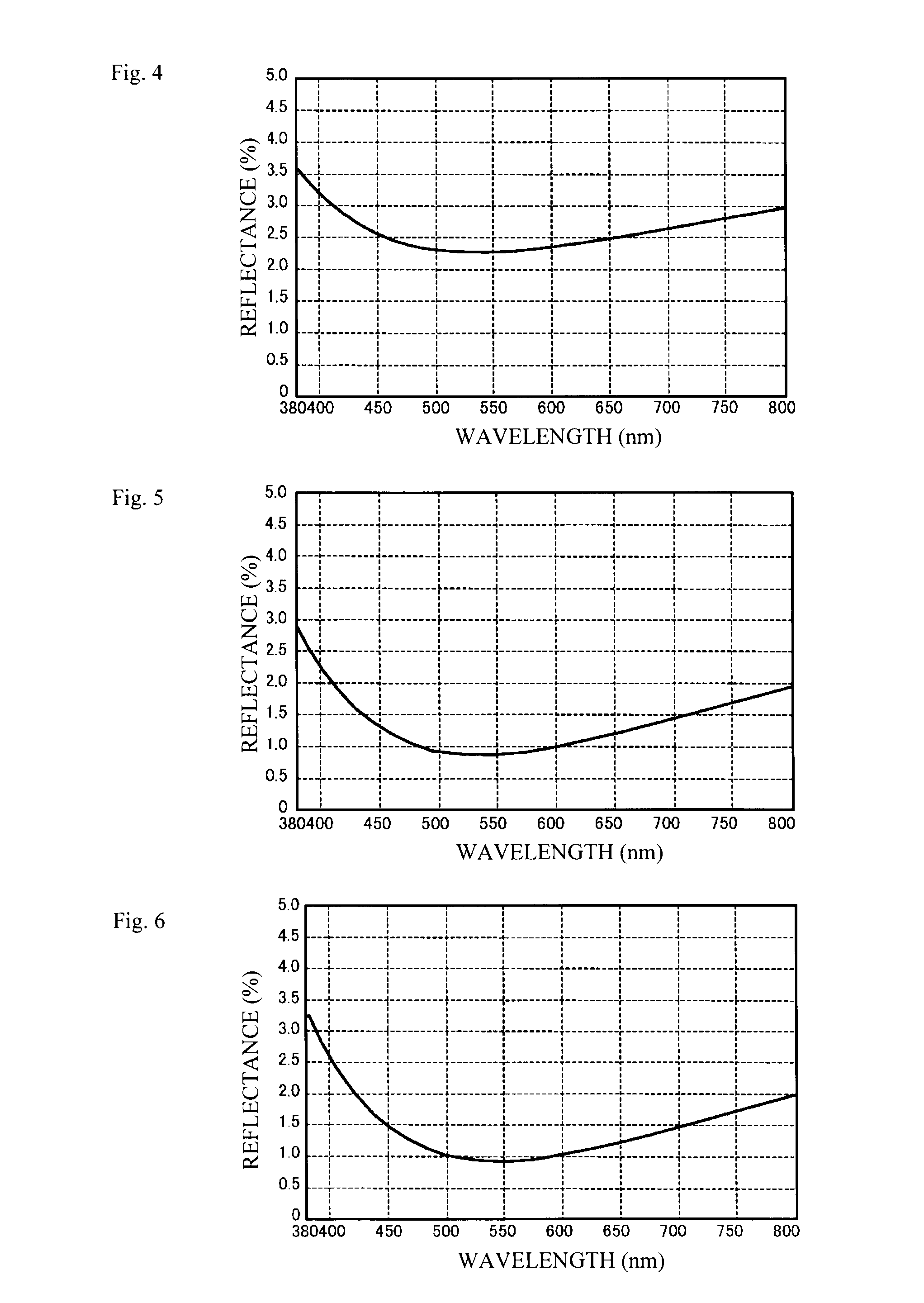

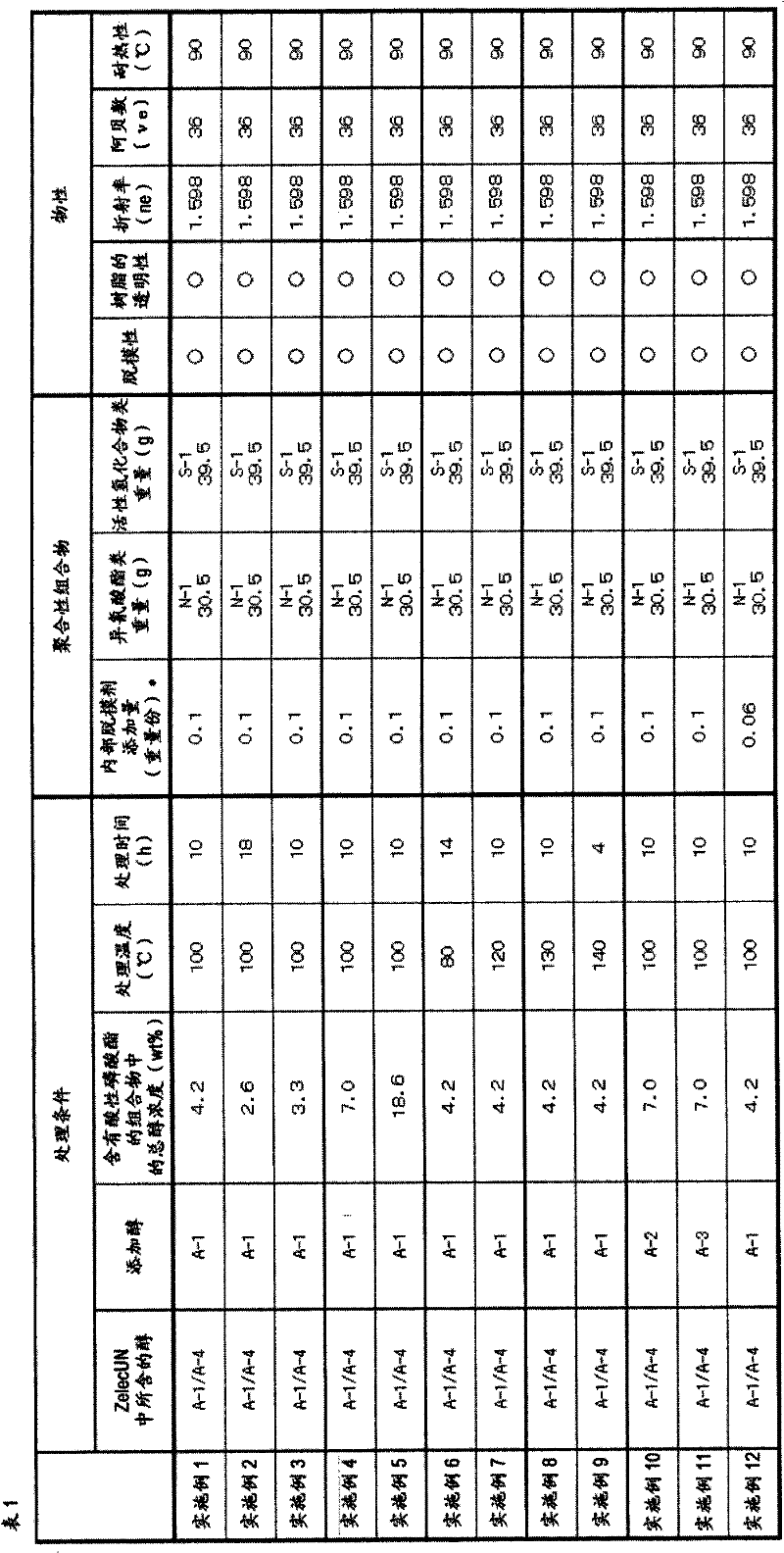

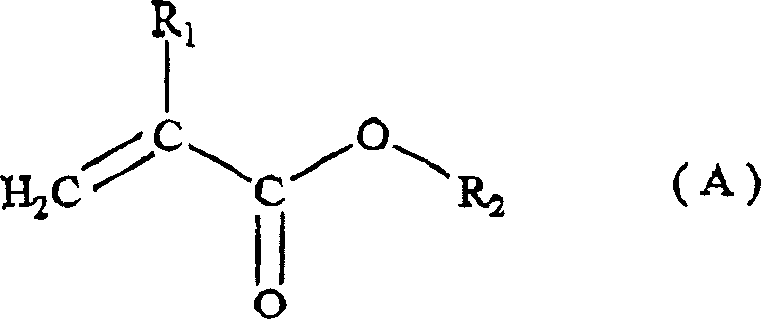

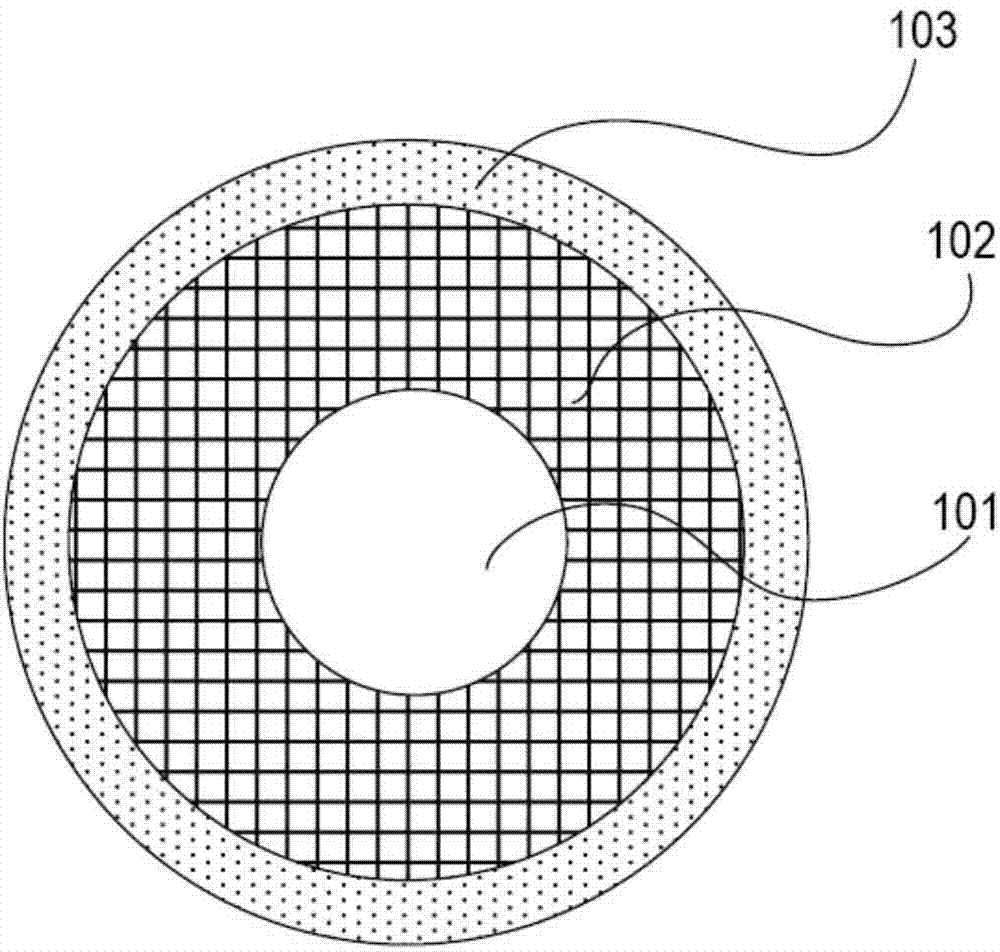

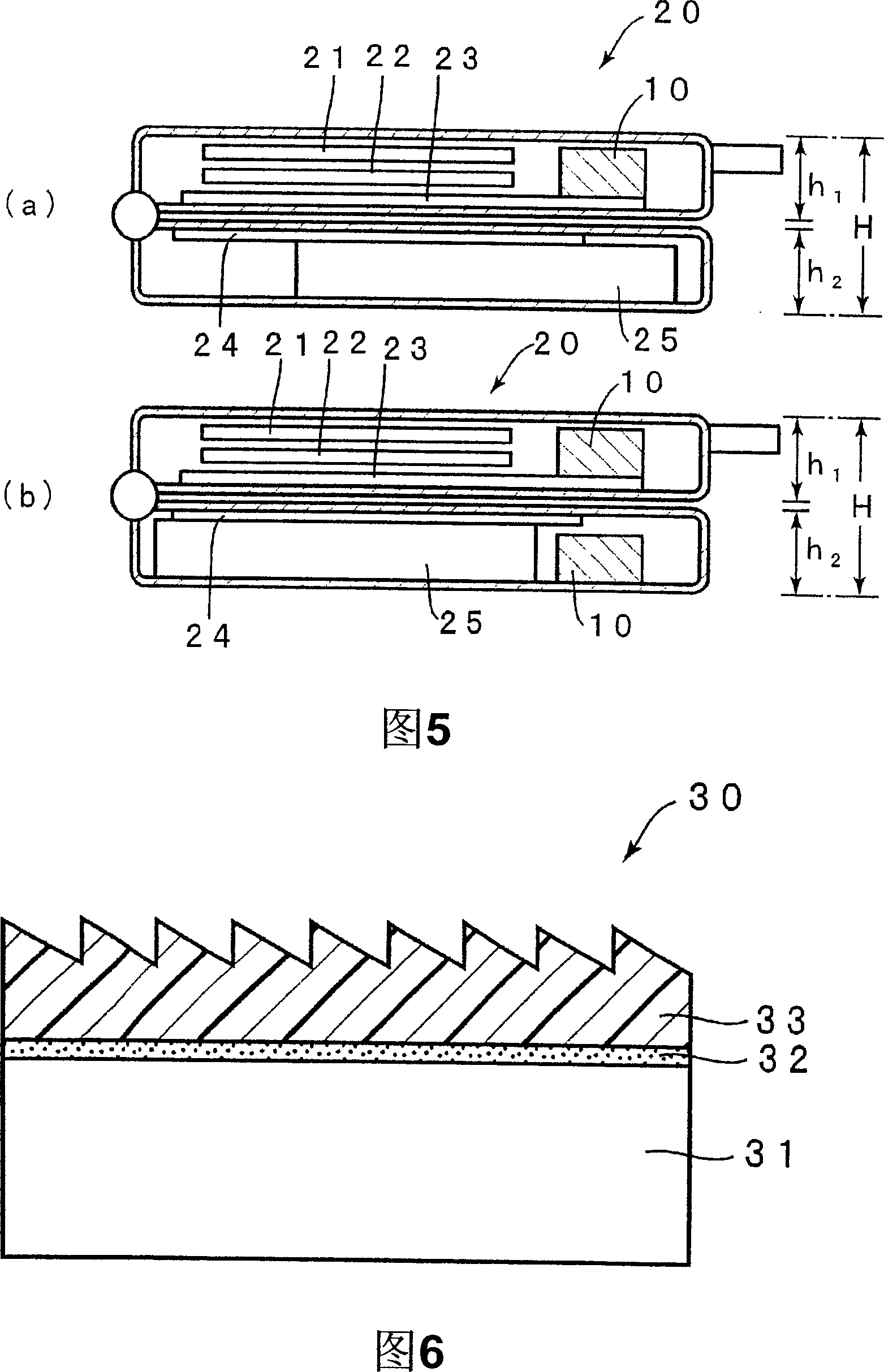

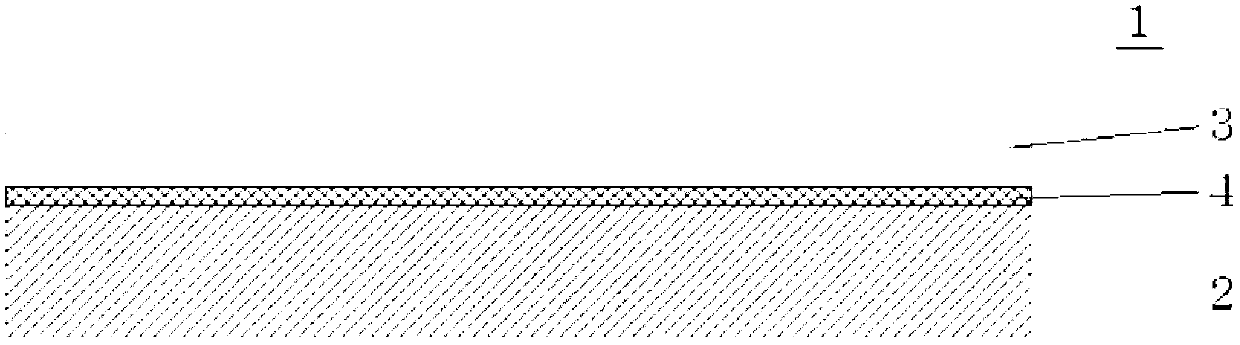

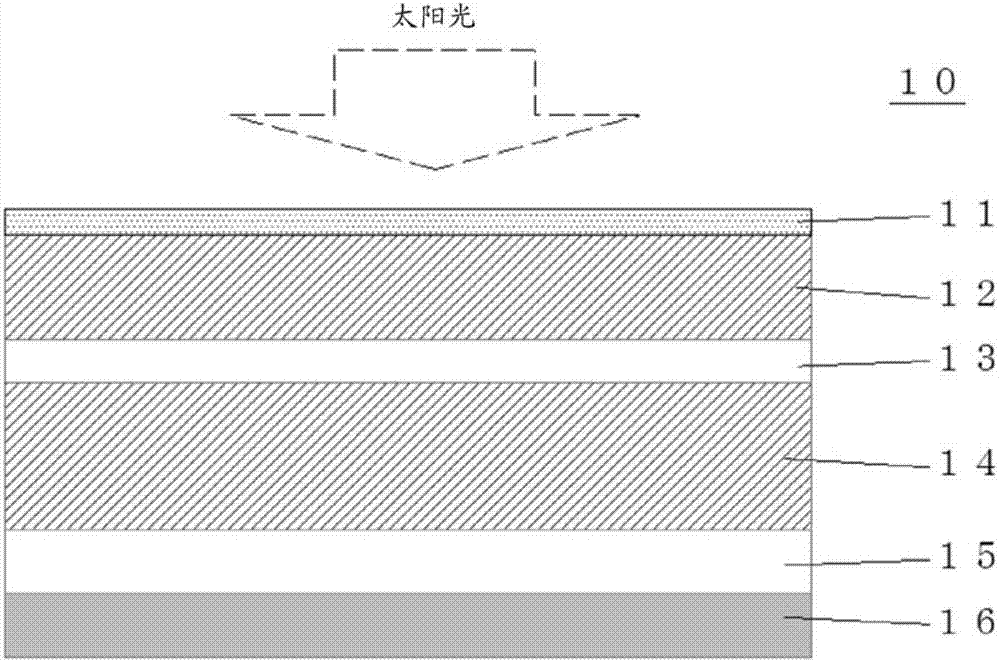

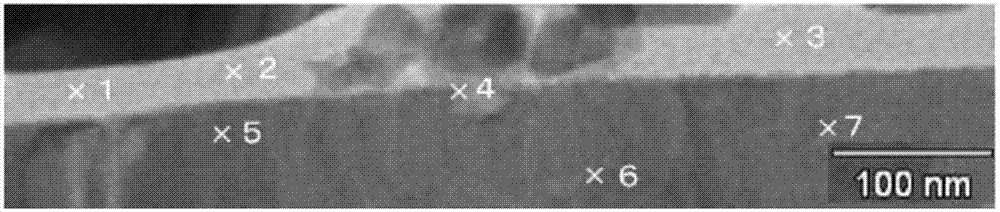

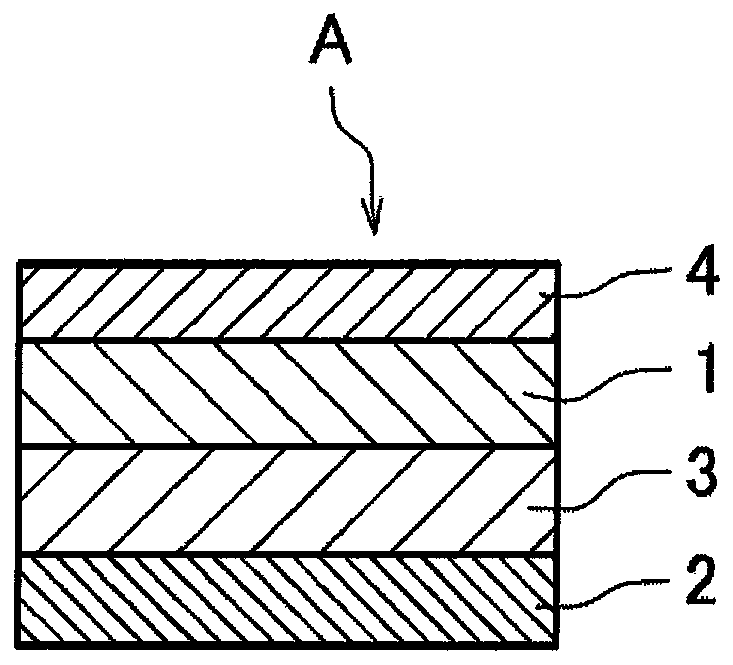

Glass substrate with anti-reflection film

ActiveCN103130420AIncreased durabilityHigh hardnessSolid-state devicesSemiconductor/solid-state device manufacturingDiffusionGeneral purpose

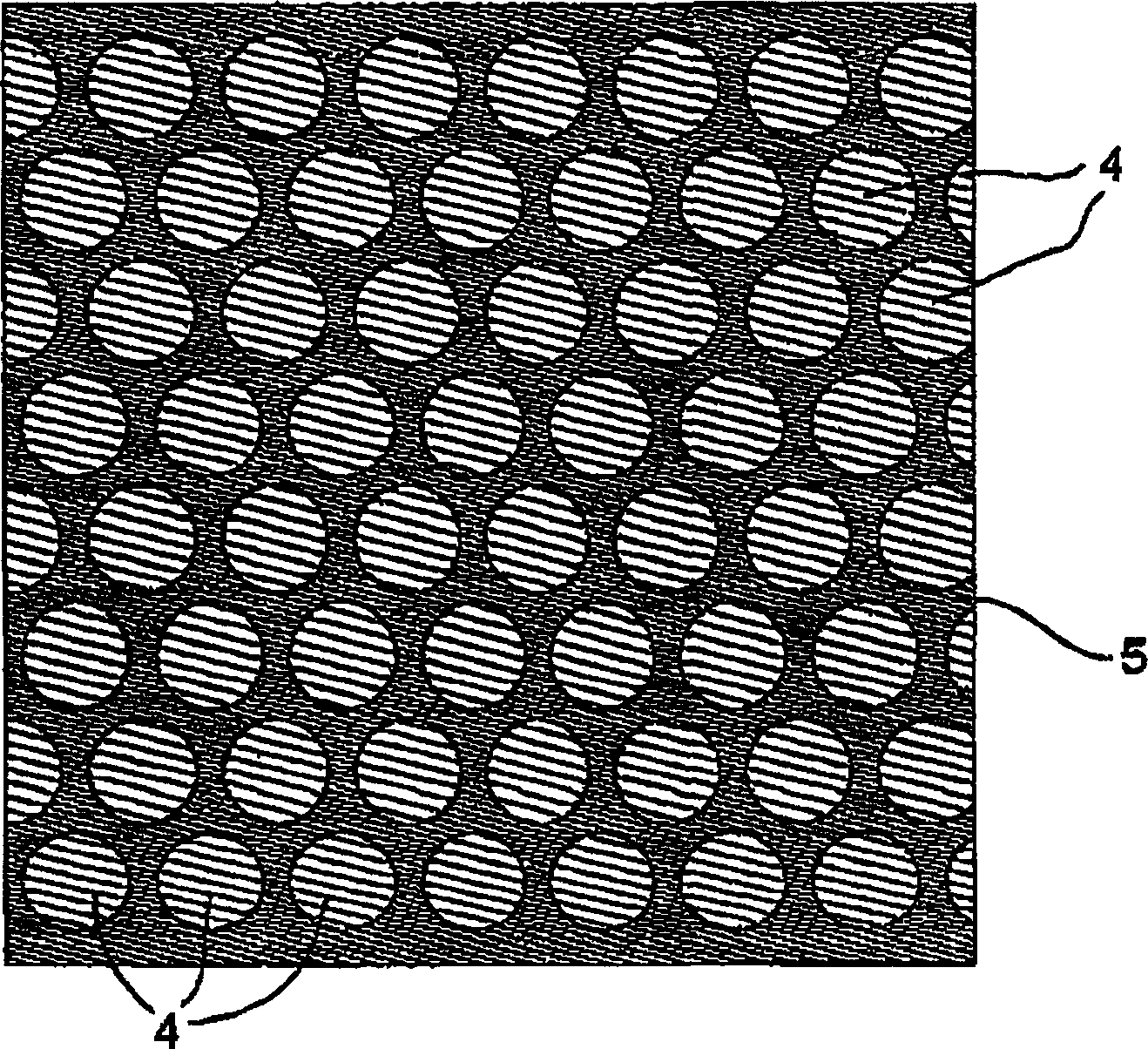

An object of the invention is to use general-purpose glass, such as soda lime glass containing Na and Ca, as a high-durability glass substrate with an antireflection film. Namely, the object of the invention is to provide a glass substrate which provides an antireflection function to increase the transmission rate of incident light, and inhibit Na or Ca in the glass substrate from diffusing to the surface of the antireflection film in high-temperature high-humidity environment, thereby inhibiting nebula of the antireflection film. The glass substrate (1) provided by the invention is a glass substrate (2) with an anti-reflection film (3), and is characterized in that, the glass substrate (2) contains at least one alkali metal selected from Na and Ca; the anti-reflection film (3) contains SiO2 and has a reflection rate of 1.35-1.50; and a diffusion inhibition film (4) containing 1-12 atom% of P is arranged on the interface of the surface of the glass substrate (2) and the anti-reflection film (3).

Owner:MITSUBISHI MATERIALS CORP

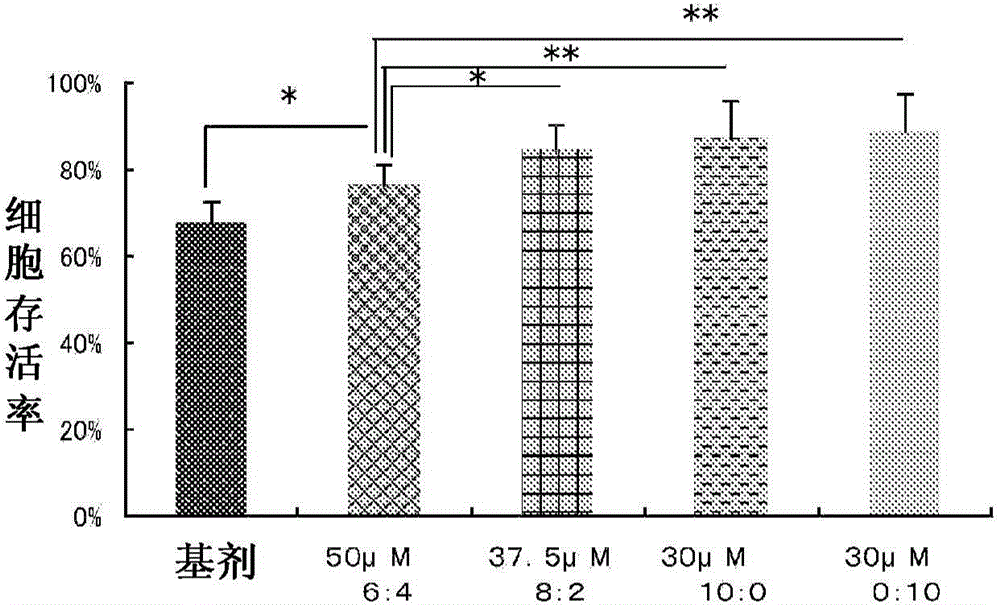

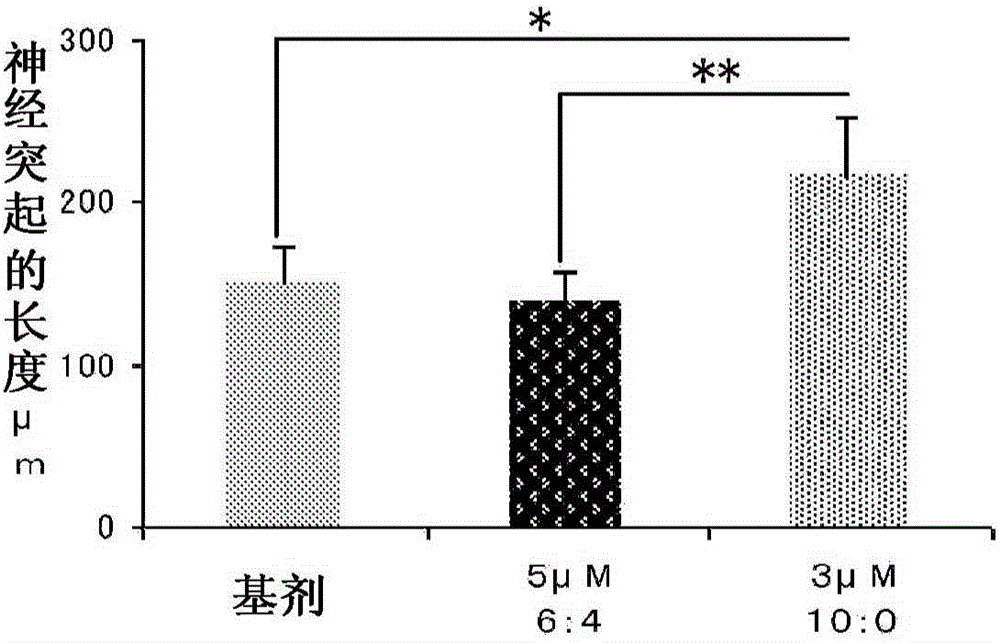

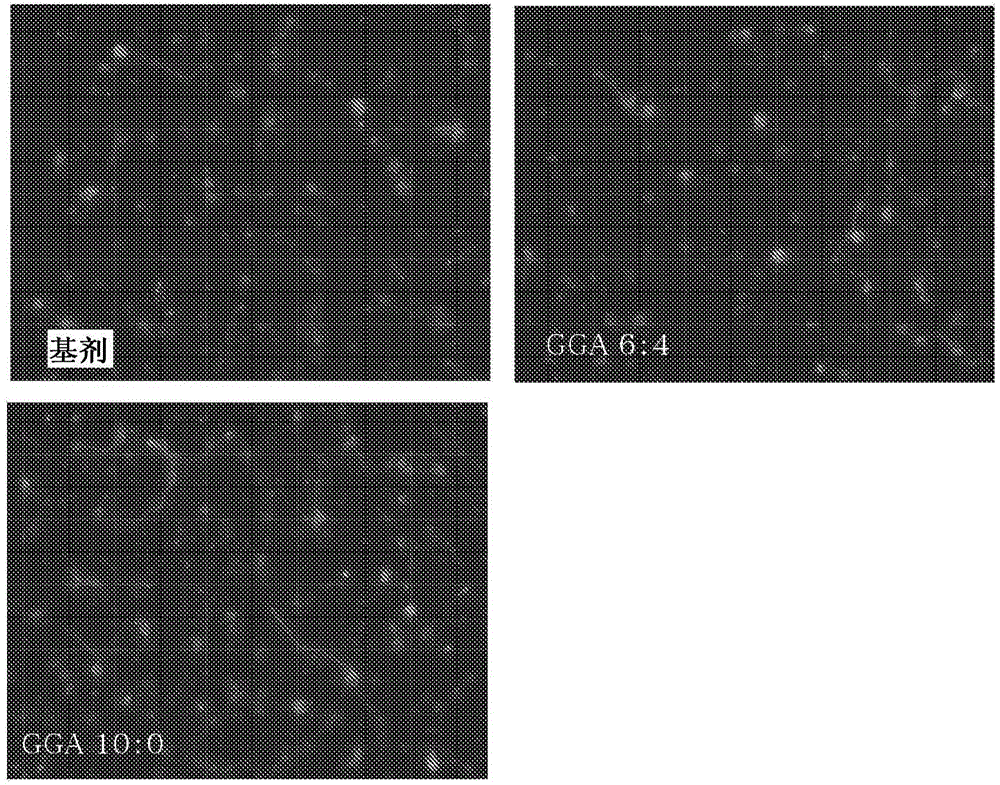

Ophthalmic composition containing geranylgeranylacetone

InactiveCN104136018AFree from sex changeFree from damageOrganic active ingredientsSenses disorderDiseaseMedicine

An ophthalmic composition comprising geranylgeranylacetone which (a) is a mixture of (5E,9E,13E)-geranylgeranylacetone and (5Z,9E,13E)-geranylgeranylacetone, the (5E,9E,13E)-geranylgeranylacetone content of the mixture being 80% by weight or more, (b) consists of (5E,9E,13E)-geranylgeranylacetone, or (c) consists of (5Z,9E,13E)-geranylgeranylacetone protects various types of retinal cells from degeneration, impairment or destruction, thereby remarkably promoting the survival. Consequently, the composition exhibits a remarkable effect of preventing, ameliorating or treating various retinal diseases. In addition, the composition hardly becomes white turbid during storage.

Owner:ROHTO PHARM CO LTD

Filler for solar cell module, solar cell module using same

InactiveCN101317275BSuppress cloudinessChemical recyclingCoatingsLow-density polyethyleneLinear low-density polyethylene

Disclosed is a filler for solar cell modules which is suppressed in white turbidity in case where a hot spot phenomenon occurs. Specifically disclosed is a filler for solar cell modules comprising a filler resin containing a silane-modified resin obtained by polymerizing an ethylenically unsaturated silane compound and a polyethylene for polymerization, and a masterbatch containing an ultravioletabsorbent, a light stabilizer, a heat stabilizer and a polyethylene for masterbatch. This filler for solar cell modules is characterized in that the polyethylene for polymerization and the polyethylene for masterbatch are composed of a metallocene linear low-density polyethylene having a density within the range of 0.895-0.910 g / cm<3>.

Owner:DAI NIPPON PRINTING CO LTD +1

Adhesive

ActiveCN1958703BGood flexibilityCurb archingNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesiveAcrylic resin

Provided is an adhesive which does not generate appearance changes at optical laminated body and has excellent durability in the condition of high temperature and humidity and repeatedly heating and cooling containing acrylic resin (1) and (2), wherein the relationship between THF insoluble component X(%) of the adhesive and Y(%) represented by formula III satisfies formula I and II: 40 <= X <= 70 (I), -0.51X +41 < 0.45X + 24 (II), Y = B - (100 - X) * C / 100 (III), wherein B is a weight percentage of the component, which has a molecular weight of no less than 300000, of the mixture of (1) and (2), and C is a weight percentage of the component, which has a molecular weight of no less than 300000, of the THF insoluble component, and (1) is the acrylic resin having a weight-average molecular weight of from 50000 to 250000, (2) is the acrylic resin containing (b) having a weight-average molecular weight of from 1000000 to 1500000, and (b) is the monomer with polar functional groups and alkene double bond.

Owner:SUMITOMO CHEM CO LTD

Uv light irradiating device

ActiveCN1725432BEfficient irradiationImprove light gathering efficiencyMechanical apparatusPhotomechanical apparatusFiberNoble gas

The present invention relates to an ultraviolet irradiation device that is capable of highly efficiently converging UV light of 300nm to 400nm, which is suitable for solidification by ultraviolet, on a light incident opening of tiny fiber with a diameter of less than 5mm; a blocking light filter that blocks ultraviolet with the harmful wavelength of less than 300nm is not used; and the ultraviolet of 300nm to 400nm can be effectively radiated on an object. The present invention is characterized in that the device is provided with a high-pressure fluorescent mercury lamp with a pair of tungsten electrodes that are arranged in a discharging container that is formed by quartz glass; mercury of 0.08 to 0.13mg / mm<3>, rare gas and halogen of 2*10<-4>~7*10<-3> [mu]mol / mm<3> are enclosed in the container; the distance between electrodes is 0.5 to 1.8 mm, which can highly efficiently irradiate the ultraviolet of 300 to 400nm; a light-converging component can converge the light from the high-pressure fluorescent mercury lamp andconverge the ultraviolet of 300 to 400nm in an area with a diameter of less than Phi 5mm so as to radiate the irradiated object.

Owner:USHIO DENKI KK

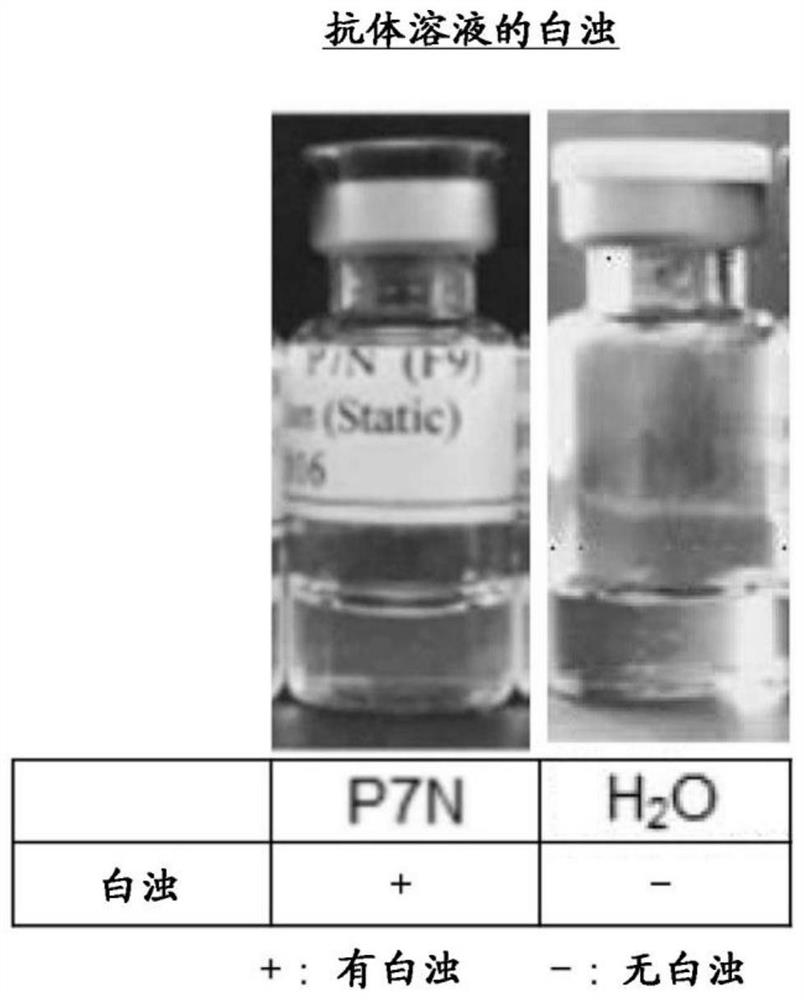

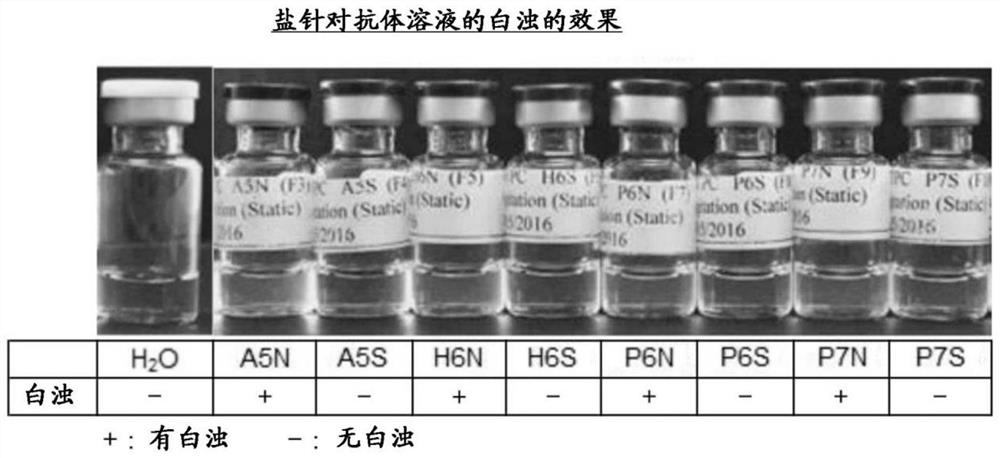

Human Anti-il-33 monoclonal-antibody-containing pharmaceutical composition

PendingCN112739378ASuppress cloudinessSuitable for usePowder deliveryInorganic non-active ingredientsAntiendomysial antibodiesBULK ACTIVE INGREDIENT

The purpose of the present invention is to provide a pharmaceutical composition containing a human anti-IL-33 monoclonal antibody suitable for administration to a subject. The present invention provides a pharmaceutical composition containing a human anti-IL-33 monoclonal antibody as an active ingredient, wherein the pharmaceutical composition is substantially free of sodium chloride or contains less than 30 mM of sodium chloride. The present invention also provides a freeze-dried form of the pharmaceutical composition.

Owner:MITSUBISHI TANABE PHARMA CORP

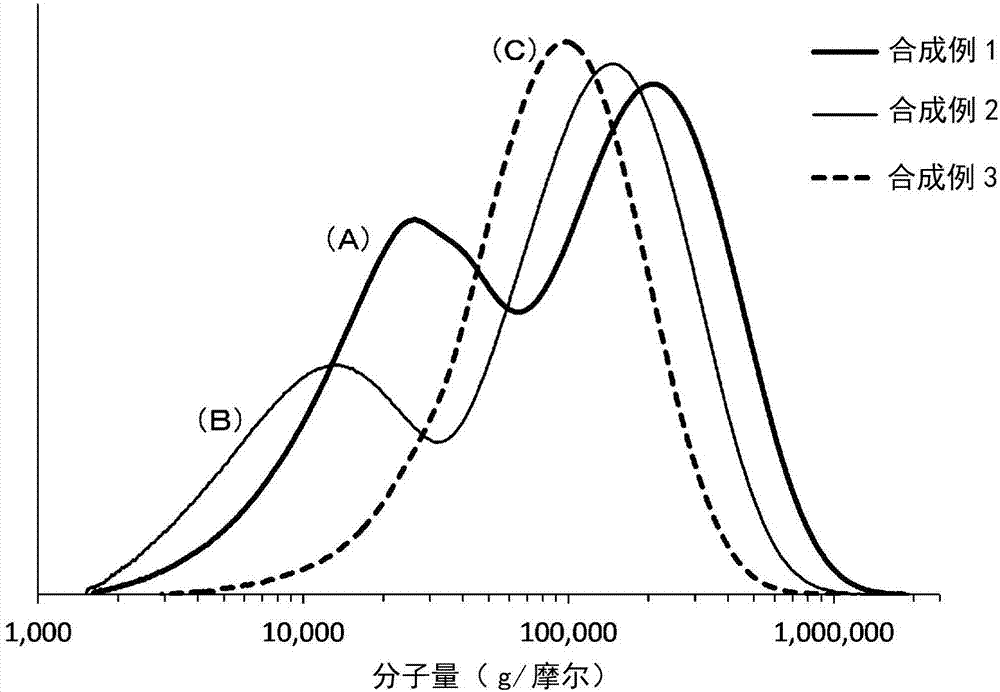

Resin composition

The present invention provides a resin composition which is a mixture of a methacrylic resin with an aromatic polycarbonate resin and which is capable of giving molded objects that are inhibited from becoming opaque and have excellent transparency. The resin composition comprises 80 parts by weight or less of an aromatic polycarbonate resin and 20 parts by weight or more of a methacrylic resin (the sum of both resins being taken as 100 parts by weight). The methacrylic resin has a weight-average molecular weight of 65,000-250,000, has a molecular-weight distribution index, which is represented by (weight-average molecular weight) / (number-average molecular weight), as large as 2.2 or greater, and contains at least 20 wt% components having molecular weights up to 40,000. The methacrylic resin, in analysis by GPC, gives a chromatogram regarding molecular-weight distribution (representative fig.) which has peak tops in positions respectively on the lower-molecular-weight side and the higher-molecular-weight side of the position having a molecular weight of 50,000, as in (A) or (B). That is, the methacrylic resin shows a so-called bimodal molecular-weight distribution.

Owner:SUMITOMO CHEM CO LTD

A method for manufacturing mold and a method for manufacturing anti-dazzle membrane

ActiveCN101712202BHigh anti-glare functionReduce contrastPhotomechanical apparatusOptical articlesCopper platingOptoelectronics

PURPOSE: A manufacturing method of a mold and a manufacturing method of a glare-proof film are provided to prevent the degradation of contrast and the generation of glittering by forming a minute concavo-convex shape on the surface of a mold. CONSTITUTION: A copper electroplating or a nickel-plating is executed on the surface(2) of a material(1) for a mold. The surface plated is ground. A light resinous film(3) is formed by spreading a photosensitive resin on the ground side. A pattern is exposed to the light resinous film. The light resinous film exposing the pattern is developed. A concavo-convex is formed in the ground plating surface by etching using the developed film as the mask.

Owner:SUMITOMO CHEM CO LTD

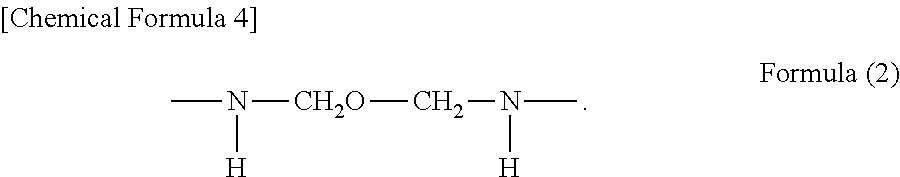

Multilayer film and method for producing same

ActiveUS20150072140A1Satisfactory transparencyAvoid it happening againLamination ancillary operationsLayered product treatmentPolyesterOligomer

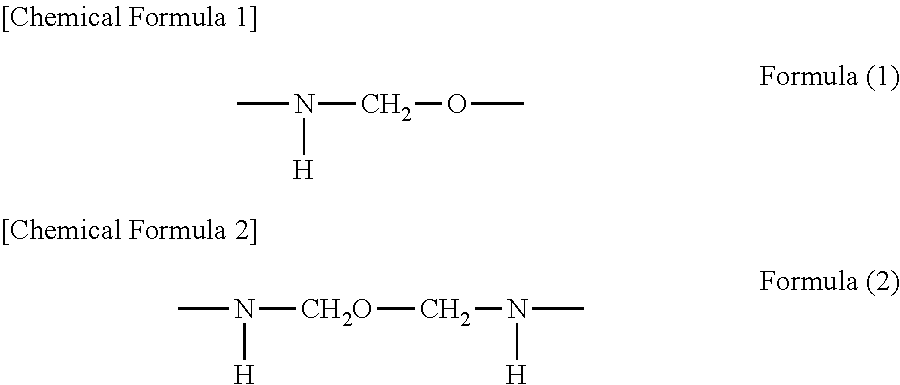

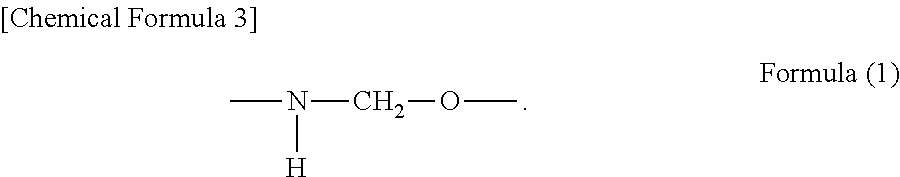

Provided is a multilayer film, in which a resin layer obtained using a resin (α) is provided on at least one surface of a polyester film, and which satisfies the conditions (I)-(IV) described below. (I) The resin layer has a thickness of 80-500 nm. (II) The resin layer has a pencil hardness of F or higher. (III) The multilayer film has a haze of 3.0% or less. (IV) The resin (α) is a resin that is obtained by heating a resin composition, which contains a resin (A) that has a hydroxyl group and an acryloyl group and a melamine compound (B) that has a methylol group, at 150° C. or higher. This multilayer film has a transparent resin layer that has a predominantly thin thickness of 500 nm or less, while having high hardness and excellent oligomer precipitation inhibiting properties.

Owner:TORAY IND INC

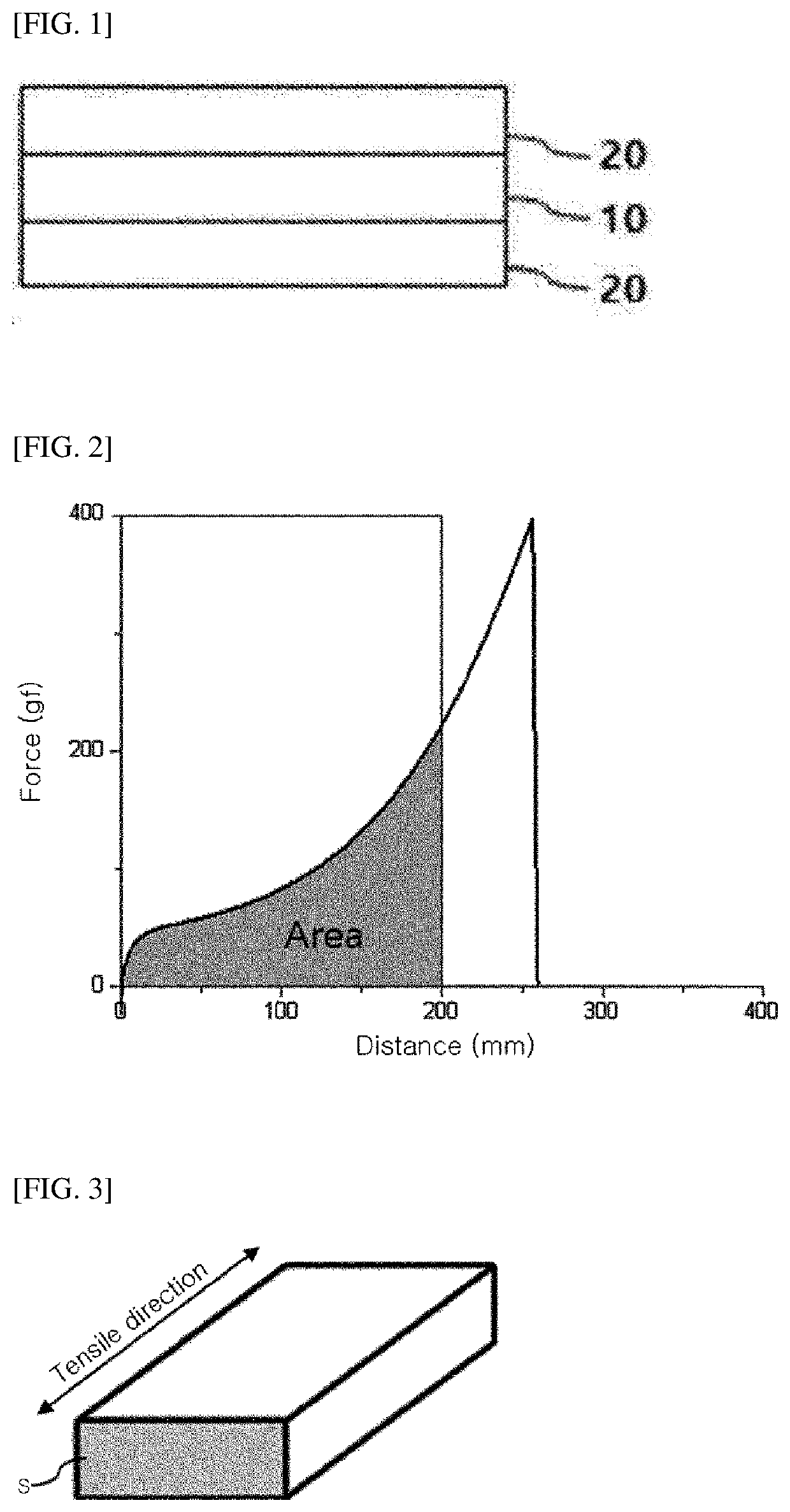

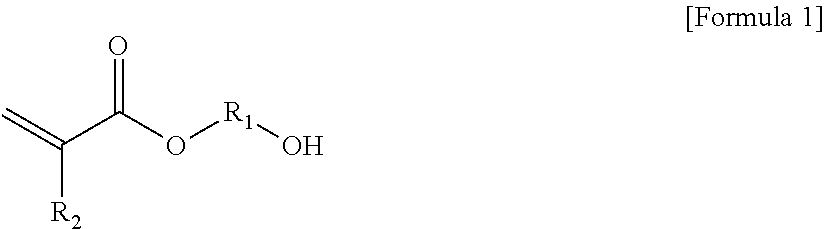

Curable Composition

PendingUS20220162359A1Fine stepsAvoid turbidityWithdrawing sample devicesMaterial strength using tensile/compressive forcesPolymer scienceUltimate tensile strength

The present application may provide a curable composition comprising a polymer component including an alkyl acrylate unit having a straight or branched alkyl group, a hydroxy group-containing monomer unit and a nitrogen-containing monomer unit, and a curing agent, and the curable composition has excellent step absorptivity, and step embedding and punching properties, and can prevent white turbidity, and is capable of implementing a low dielectric constant and improving the punching performance and handling properties. Even if such a curable composition according to the present application is applied to a stepped substrate or the like, it may prevent lifting or delayed bubbles from being generated in the step portion. In addition, the pressure-sensitive adhesive film comprising the cured product formed from the curable composition may have excellent tensile strength.

Owner:KOZA NOVEL MATERIALS KOREA CO LTD

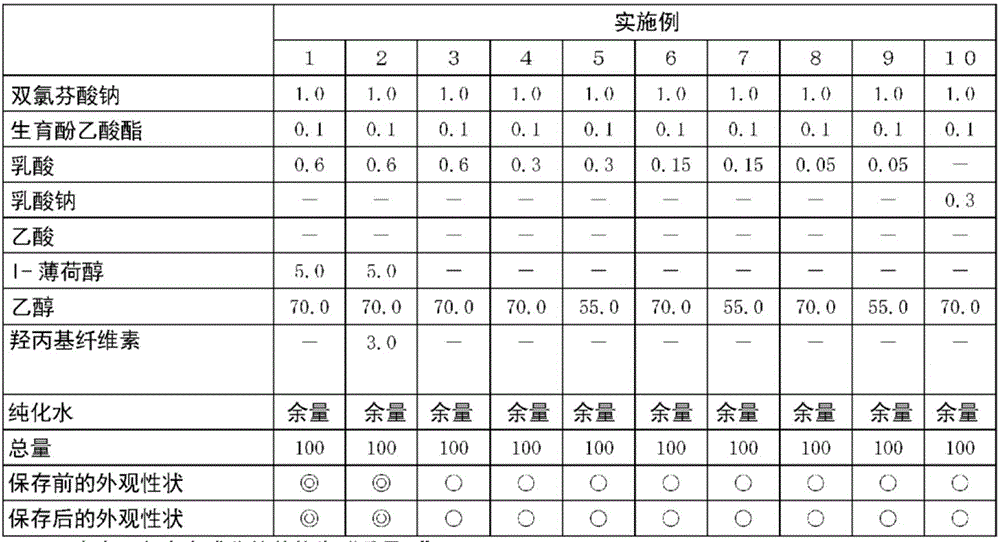

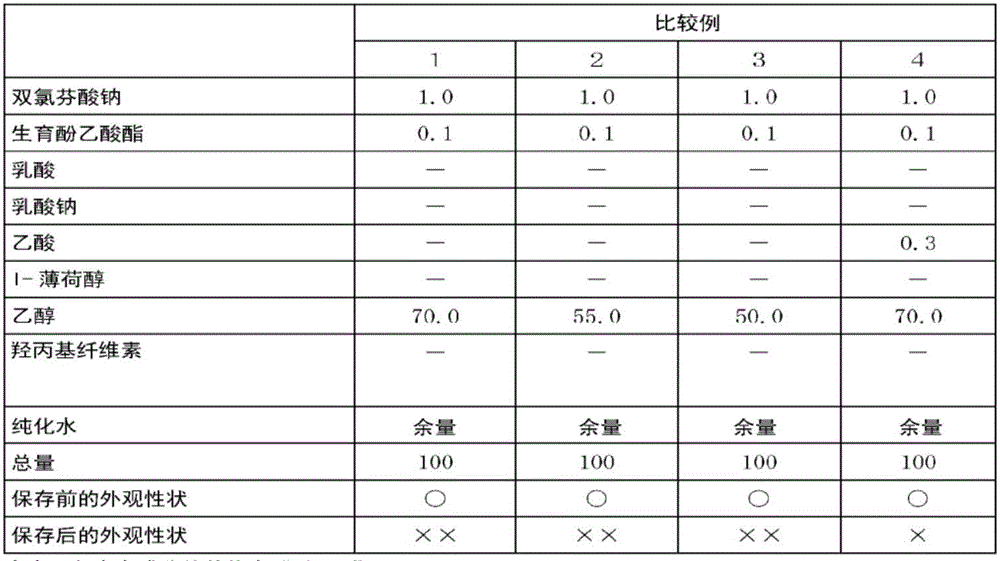

External pharmaceutical composition

ActiveCN106413699AInhibit yellowingExcellent storage stabilityAntipyreticAnalgesicsChemistryTocopherol

Owner:KOBAYASHI PHARMA CO LTD

Glass substrate with anti-reflection coating

ActiveCN103130420BIncreased durabilityHigh hardnessSolid-state devicesSemiconductor/solid-state device manufacturingGeneral purposeHigh humidity

An object of the invention is to use general-purpose glass, such as soda lime glass containing Na and Ca, as a high-durability glass substrate with an antireflection film. Namely, the object of the invention is to provide a glass substrate which provides an antireflection function to increase the transmission rate of incident light, and inhibit Na or Ca in the glass substrate from diffusing to the surface of the antireflection film in high-temperature high-humidity environment, thereby inhibiting nebula of the antireflection film. The glass substrate (1) provided by the invention is a glass substrate (2) with an anti-reflection film (3), and is characterized in that, the glass substrate (2) contains at least one alkali metal selected from Na and Ca; the anti-reflection film (3) contains SiO2 and has a reflection rate of 1.35-1.50; and a diffusion inhibition film (4) containing 1-12 atom% of P is arranged on the interface of the surface of the glass substrate (2) and the anti-reflection film (3).

Owner:MITSUBISHI MATERIALS CORP

Solvent-free urethane composition

ActiveCN1894299BReduce loadHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolSolvent free

Disclosed is a solvent-free composition containing a polyol component (A) and a polyisocyanate component (B) wherein the polyol component (A) is composed of a low molecular weight polyol (A1) having a molecular weight of not more than 350. The viscosity of the low molecular weight polyol (A1) may be 500 mPa.s or less at 25 1 / 2 C, and the low molecular weight polyol (A1) may be, for example, a C2-6 alkylene glycol. Alternatively, the polyol component (A) may be composed of the low molecular weight polyol (A1) as a diluent and a polymer polyol (A2). The polyisocyanate component (B) may be a modified body or derivative of a polyisocyanate (such as a polymer of a diisocyanate). The solvent-free composition may further contain an epoxidized compound (C) which may optionally contain a hydroxyl group (such as an aliphatic diol glycidyl ether or an aliphatic polyol glycidyl ether having a hydroxyl group). This solvent-free composition causes only small damage to the environment, and has excellent coating properties and a high working efficiency.

Owner:日本硅石株式会社

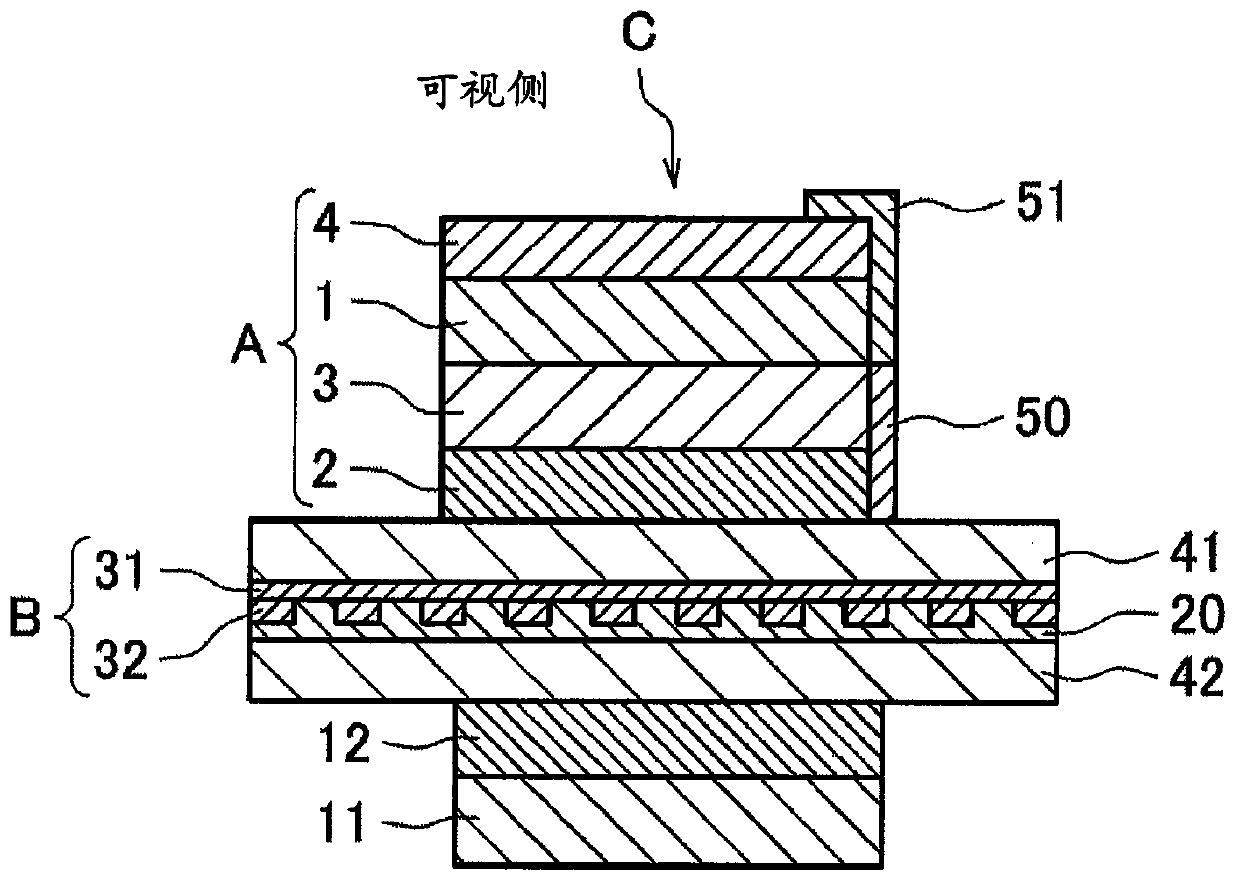

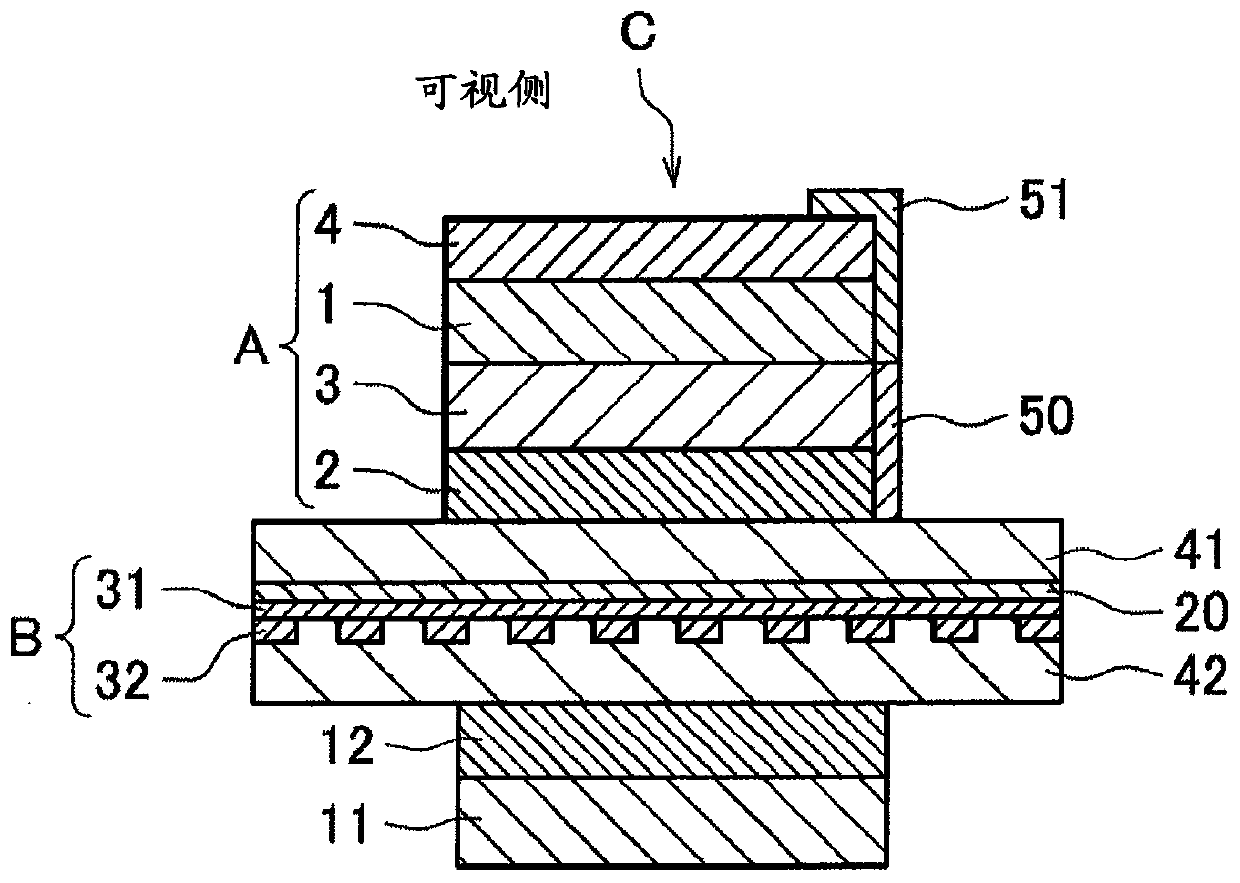

Polarizing film with added adhesive layer, polarizing film with added adhesive layer for in-cell liquid crystal panel, in-cell liquid crystal panel, and liquid crystal display device

PendingCN110476093AEnsure continuityGuaranteed contact areaNon-macromolecular adhesive additivesFilm/foil adhesive primer layersAntistatic agentLiquid-crystal display

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com